Okay, so I want to implement a mash cap and was thinking about purchasing the NorCal Brewing set-up. @Bilsch and Bracc (RIP) had helped design it, but it needs more.

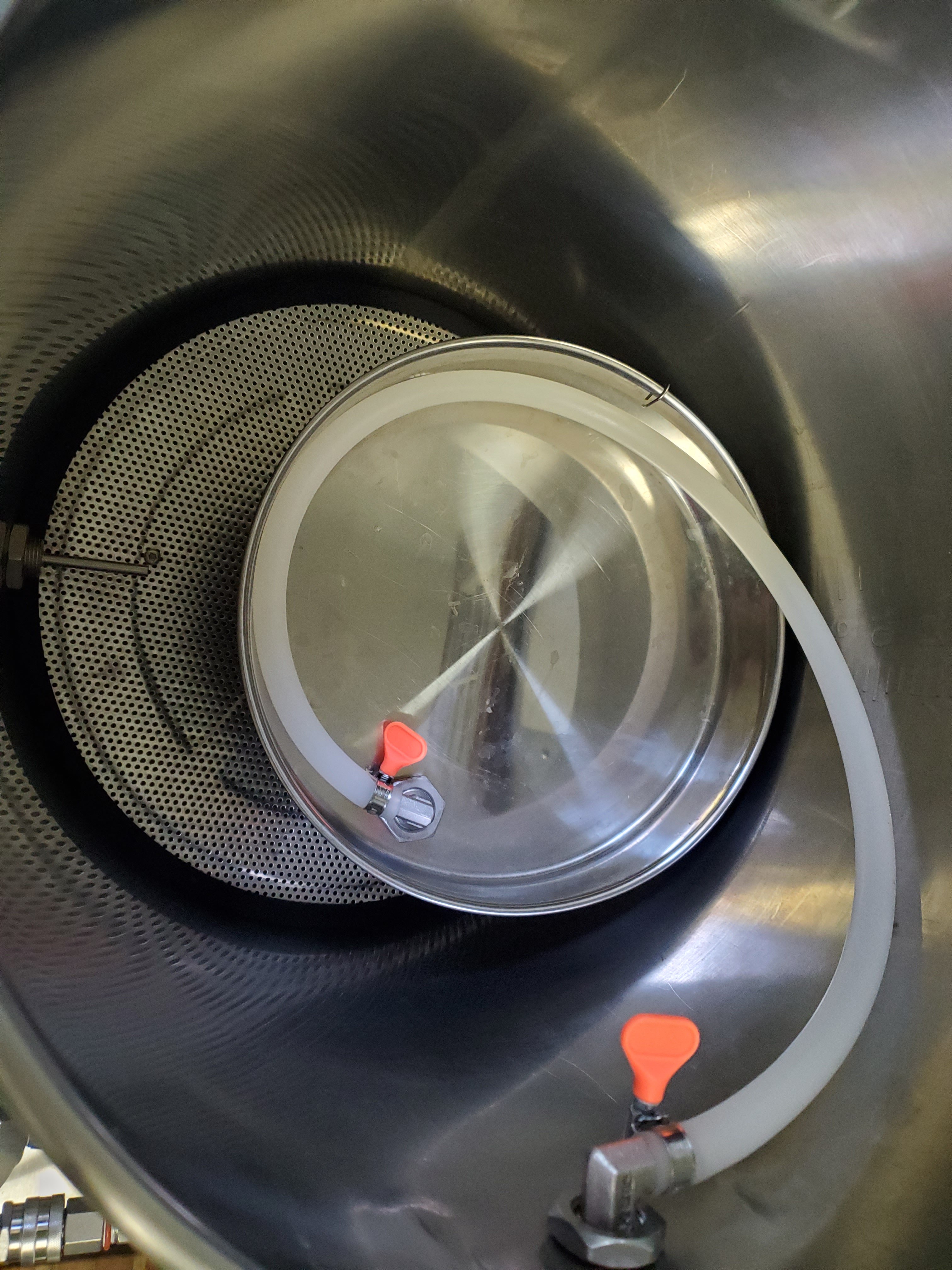

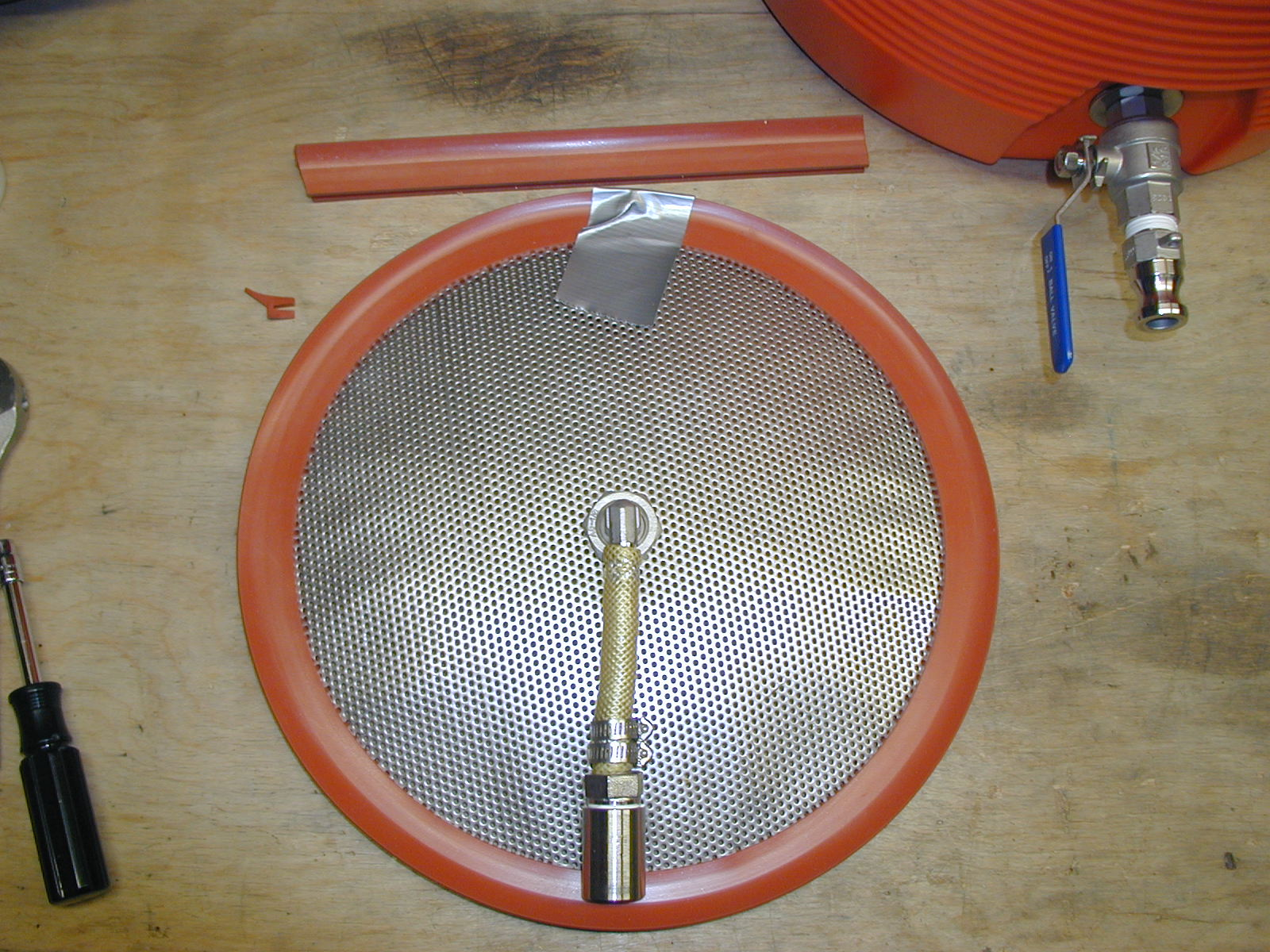

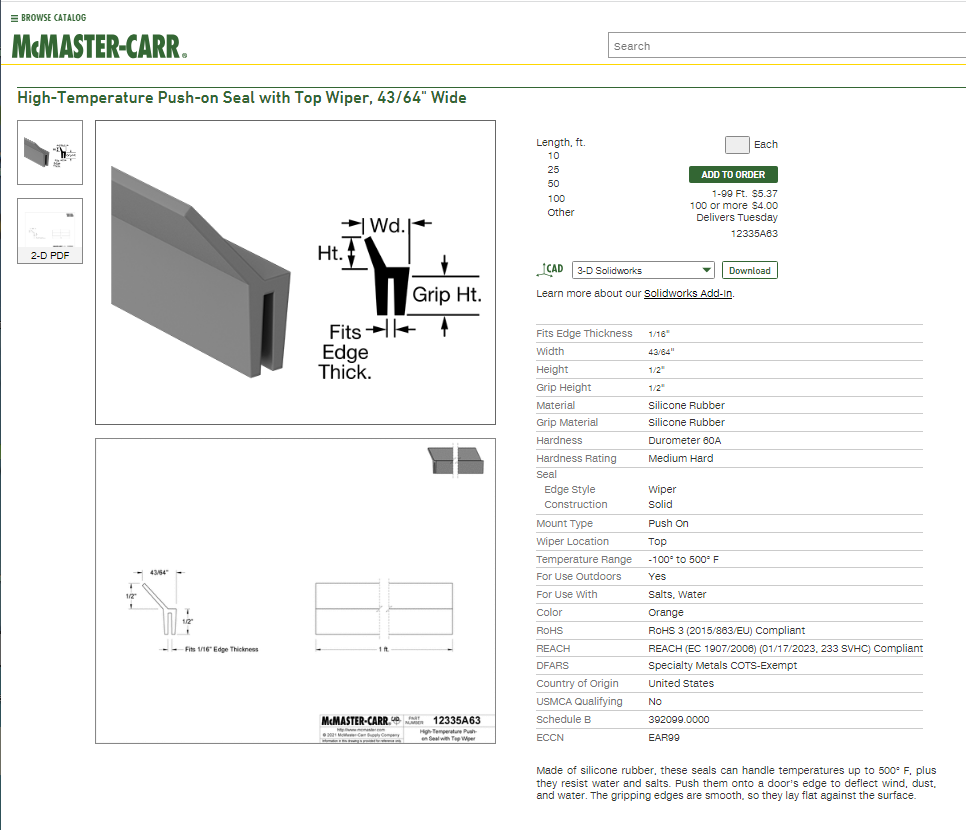

Has anybody used that piece, either the way it was sold or any mods to it? If not, what's your set-up? Pictures appreciated. I have a Spike 15G mash tun in an eHERMS set up and I fly sparge.

Thanks!

Has anybody used that piece, either the way it was sold or any mods to it? If not, what's your set-up? Pictures appreciated. I have a Spike 15G mash tun in an eHERMS set up and I fly sparge.

Thanks!