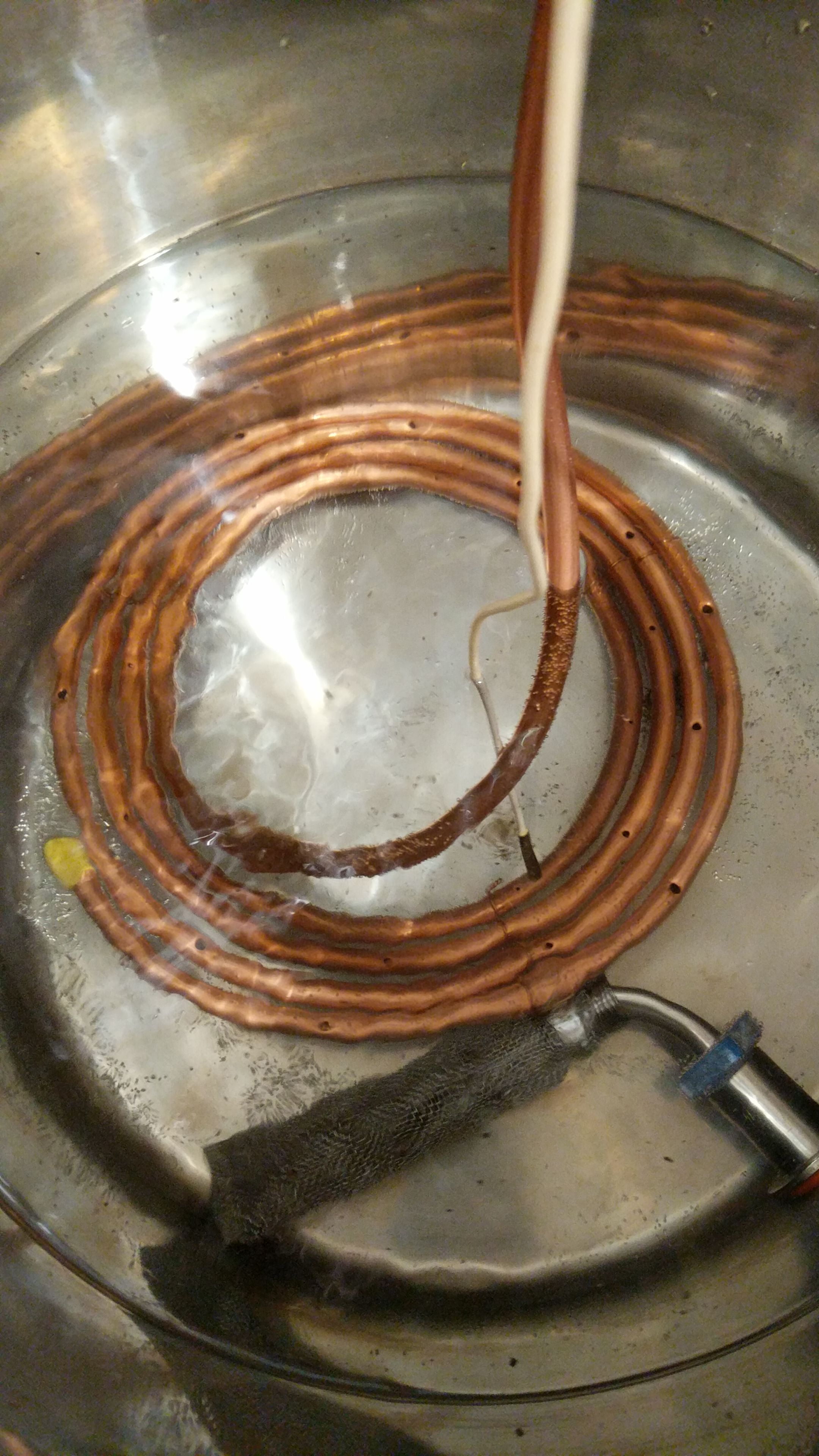

OP, make sure you really do stir it frequently! I've done the same thing as you but I didn't stir as often as I should have; I was still monitoring the middle of the mash with a probe but I decided to measure the wort at the bottom of the pot and it was almost at mash out temp! In the winter I brew inside on the stove. I'm trying to improve my process and maintaining temp without stirring was one that I figured I could improve upon. I wanted to have a small amount of evenly distributed heat input so I just tested a circ pump tonight with water. I found a 3-3.5 on the large burner with the circ pump on works perfectly at maintaining temp  !

!

I can't wait to use this! Will be great for step mashing too. Obviously the recirc manifold will go in the bag itself. I just need to see if the bazooka screen is enough to not "pack off" the suction with the grain bag. If it does I may have to add a false bottom.

Not sure what others' experiences have been with recirc pumps like this but I'm guessing this will be a game changer for me. No more messing around with stirring/insulation.

I can't wait to use this! Will be great for step mashing too. Obviously the recirc manifold will go in the bag itself. I just need to see if the bazooka screen is enough to not "pack off" the suction with the grain bag. If it does I may have to add a false bottom.

Not sure what others' experiences have been with recirc pumps like this but I'm guessing this will be a game changer for me. No more messing around with stirring/insulation.

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)