toddo97

Well-Known Member

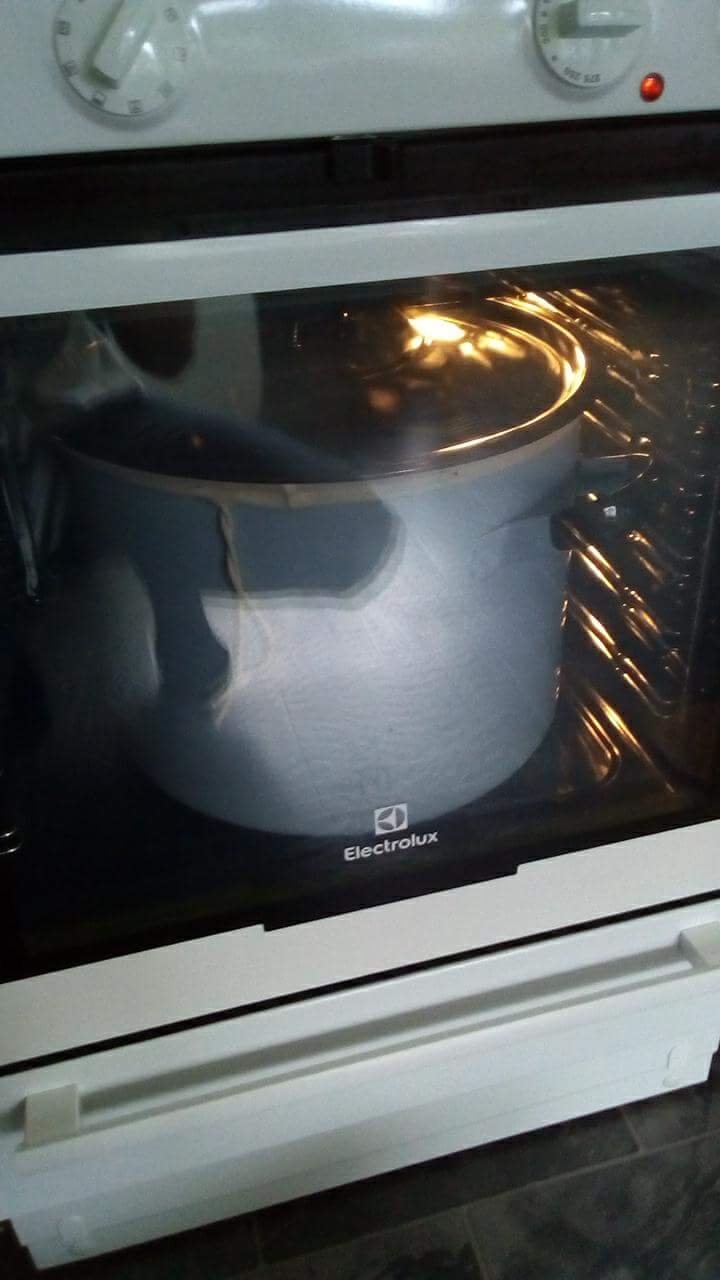

I have two BIAB brews under my belt and am getting ready to brew this weekend. I mash on my electric stovetop and rather than doing the blanket wrap thing to maintain my mash temp, I just set the burner on low and frequently stir for the hour. My temps stay pretty steady and since it's low, there's no scorching/melting of the bag. Is this a legit thing to do or am I asking for trouble doing it this way? It seems like a good way of maintaining temps, but I don't see many (any?) people doing it like this.