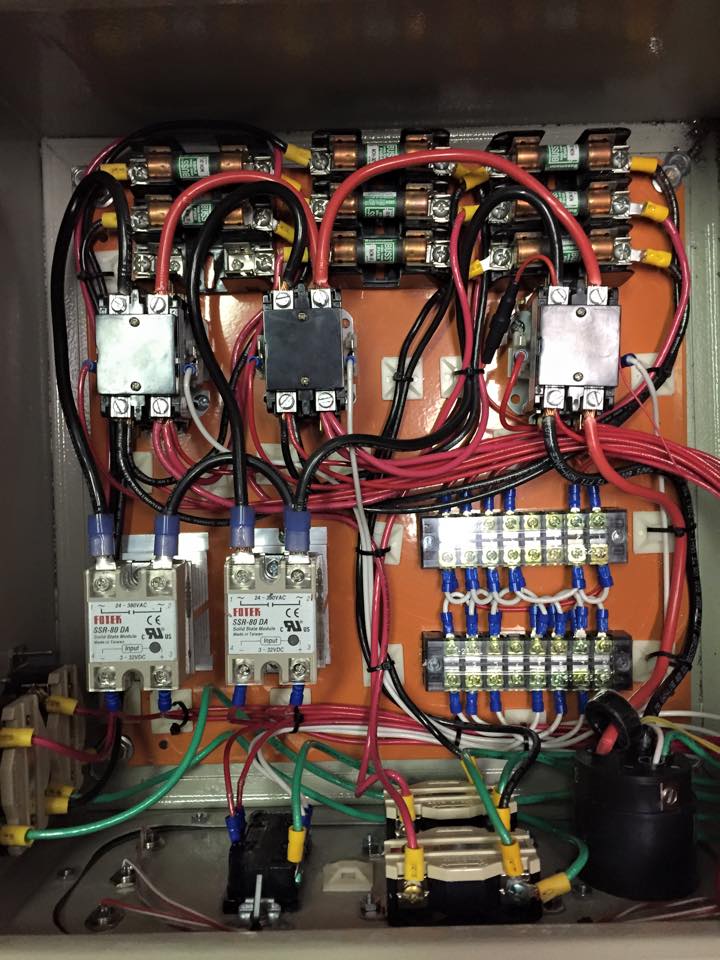

Got my circuit installed and finally I was able to test the control panel, everything is working 100%!

Had a 3 problems with it that I was able to fix on the same day. First, the volt/amp meter, as soon as I connected the power cable, it would light up and show 86V, when I would turn on the switch it would read the entire 240v, then when I would turn the switch off, it would stay on! Scratched my head for a while on this, the volt/amp meter must have some type of capacitor that keeps the relay open, so instead of having it read the voltage off the switch, I had it read one end of the voltage from the power led and the other end reads the voltage from the normally open side of the relay.

My pid's were reading around 1500 degrees haha, went back to the electricbrewery and found there were some things I needed to config on them.

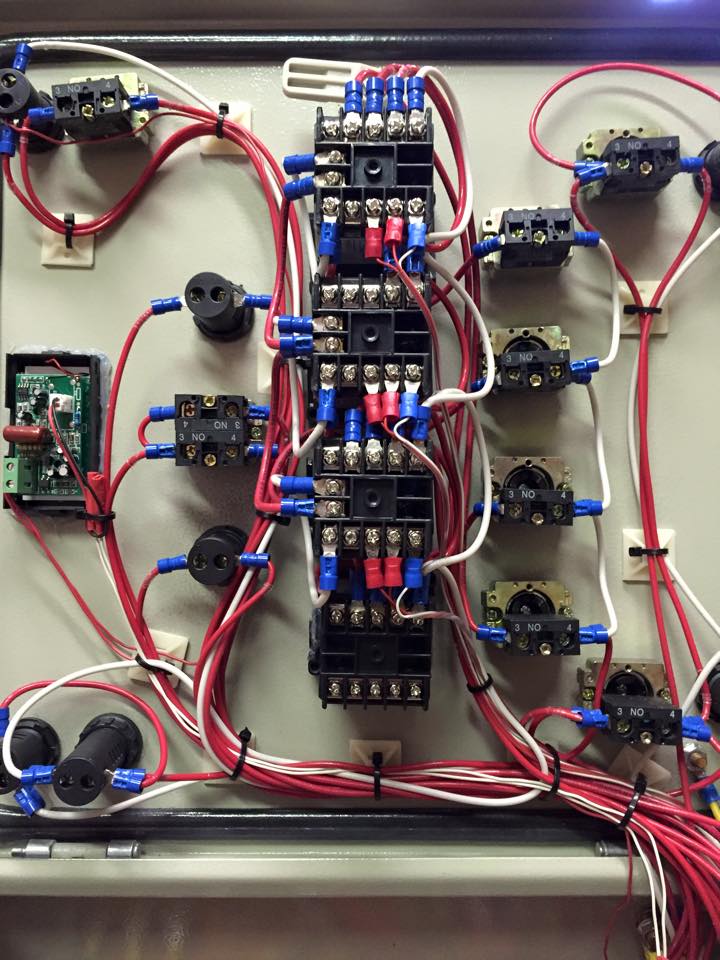

As soon as I would turn on one pump, the other one would turn on as well. I went through my wiring, checked everything and asked myself what the hell was going on, then I found these outlets are bridged. I went back to home depot and asked for one that wasn't and I was told they didn't exist. I got pretty frustrated at this point because another one wouldn't fit in my control panel. Finally I looked online and say that the bridge can be easilly removed with pliers

Oh, one other thing, for some reason my key operated switch works with or without a key haha

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)