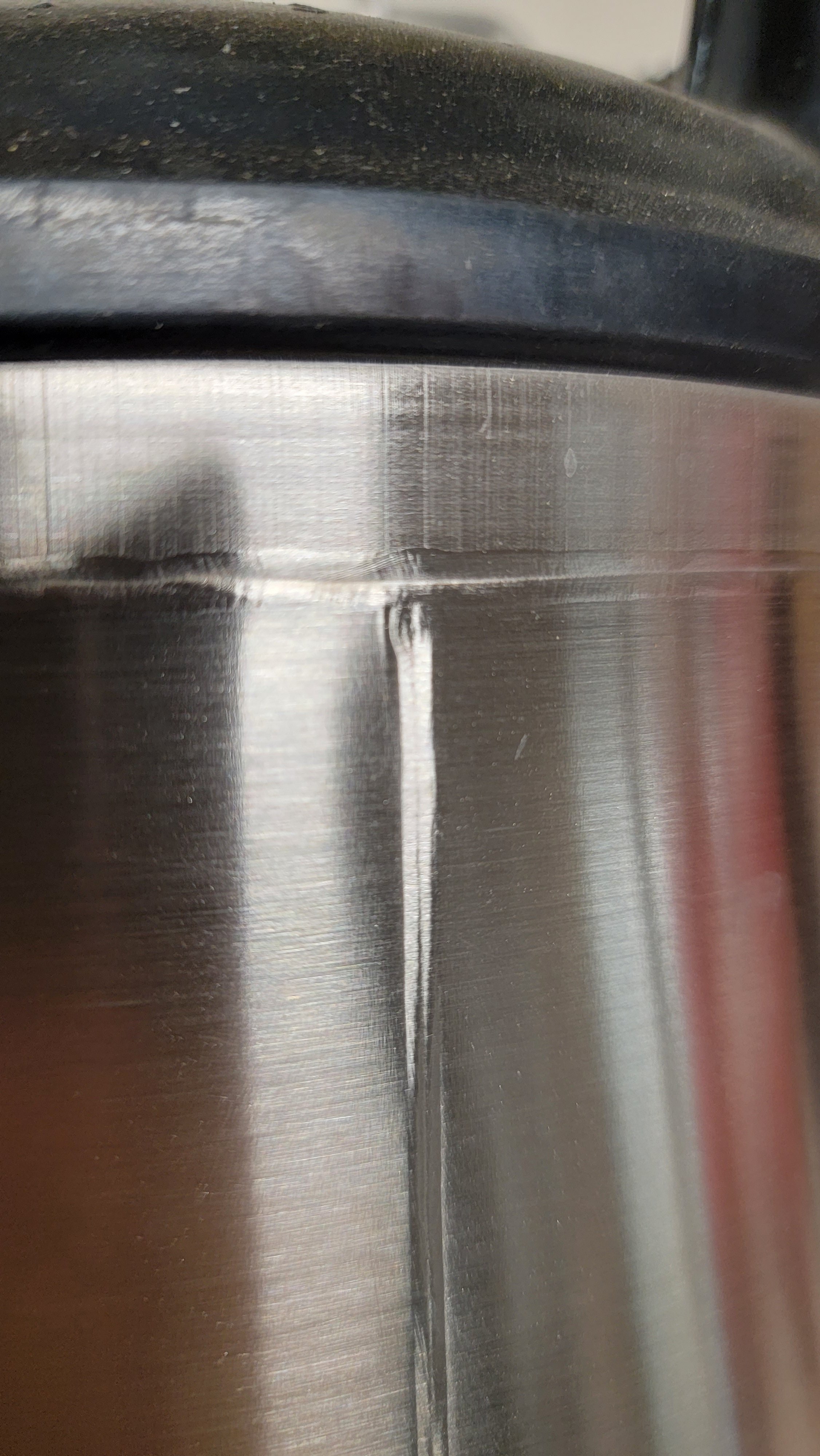

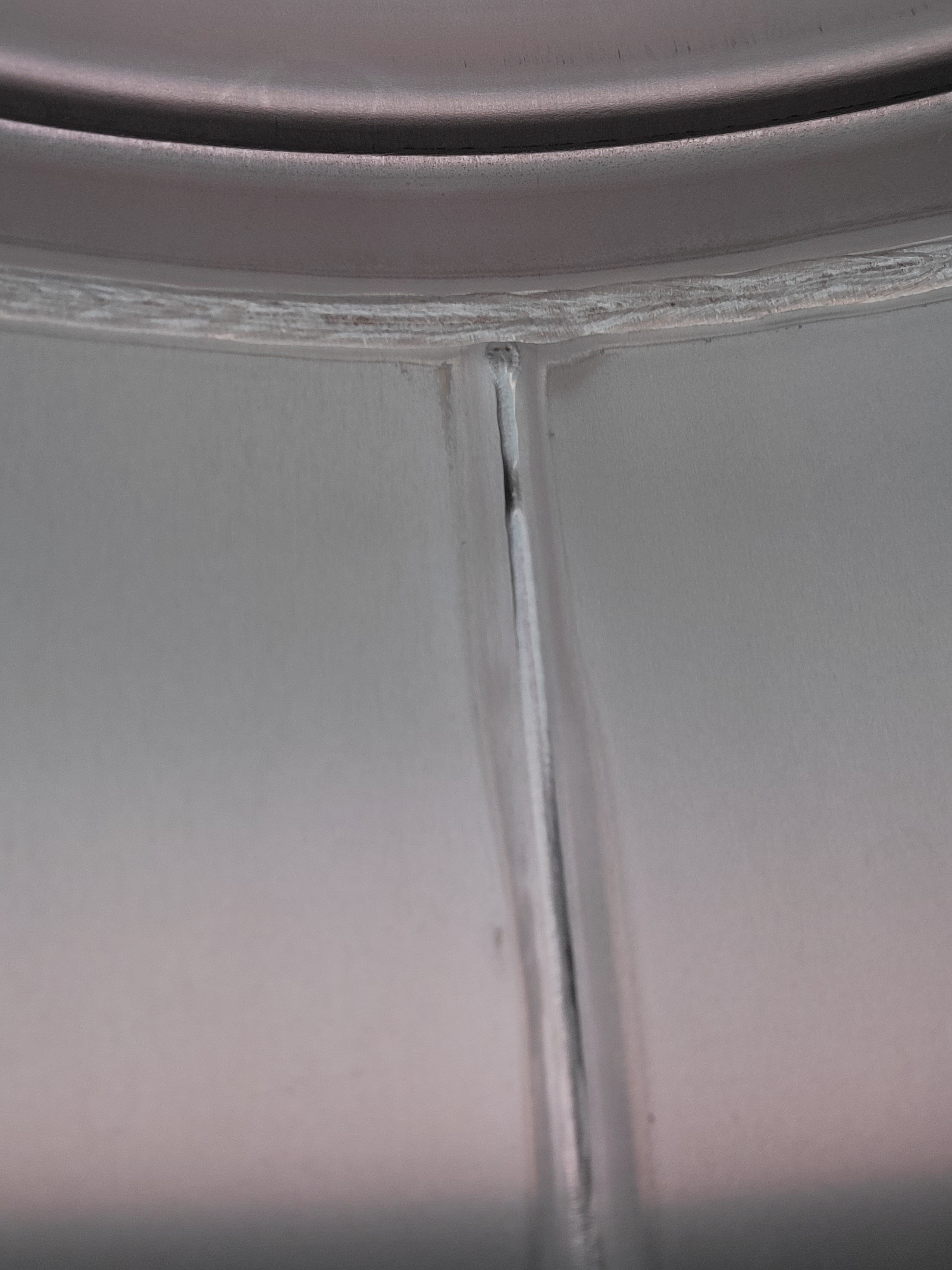

It's been a while since I've been in the welding process line of work, but face cracking is a sign of the weld puddle cooling too quickly and shrinking (or not a "good seam fill") - as in travel speed vs "power parameters".

Not to say the seam won't hold, but ... sure gives a poor appearance - refer to the top of the shown vertical seam - profile is just ok, it looks fairly clean.

However, approaching the intersection of the vertical/horizontal seams, the vertical weld has less fill and appears to show porosity at the stop point.

For me, my next 2.5 keg will be another keg brand - my $0.02..

Oh - one more - I replaced all the torpedo dip tubes with conventional non-ear flared tubes.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)