Carlyle

Well-Known Member

Hello to all my fellow brewer and beer drinkers!

I've been home brewing on a hillbilly set up now for almost 20 years and must say i have come up with many a fine brew over that time. A friend of mine started brewing with me about 3 years ago and I've been inspired by him to make my brewing more efficient and easier. The cinder blocks and camp stoves get a little old at times...

I recently finished the build on a new garage/man cave and now have a better place to brew!

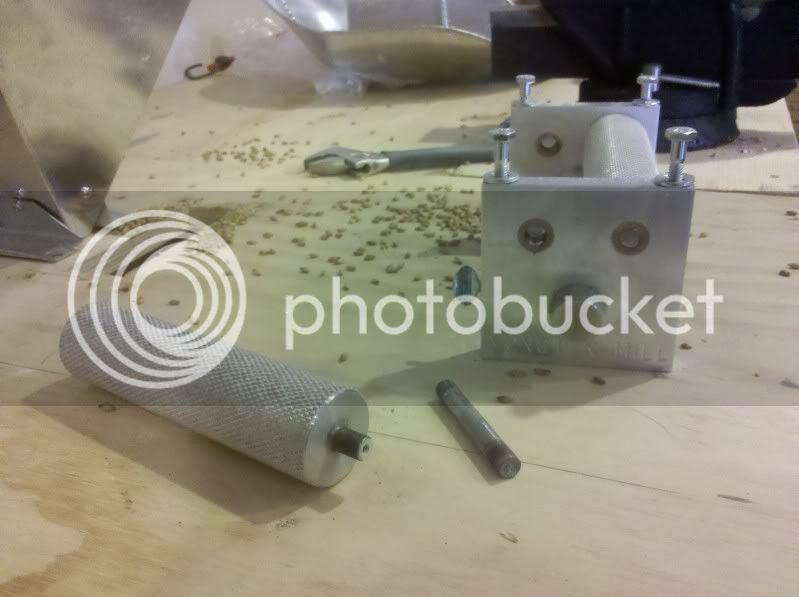

I had a workbench installed and now my new mill is built in and ready to crush.

Grain Silo

I just got the go ahead and my single tier brew stand is being welded up.

More pictures as it comes along.

I've been home brewing on a hillbilly set up now for almost 20 years and must say i have come up with many a fine brew over that time. A friend of mine started brewing with me about 3 years ago and I've been inspired by him to make my brewing more efficient and easier. The cinder blocks and camp stoves get a little old at times...

I recently finished the build on a new garage/man cave and now have a better place to brew!

I had a workbench installed and now my new mill is built in and ready to crush.

Grain Silo

I just got the go ahead and my single tier brew stand is being welded up.

More pictures as it comes along.