Trouble_Brewing

Well-Known Member

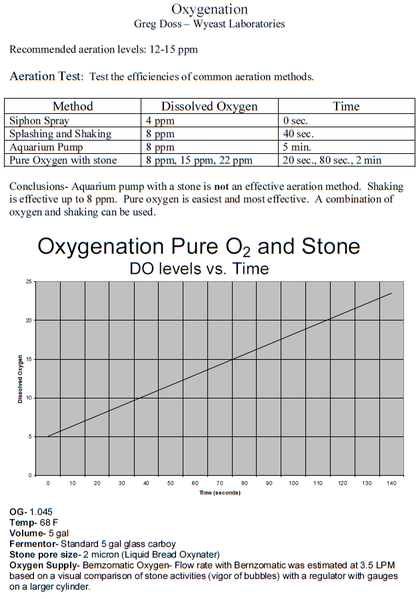

OK, I've been trying to track down an answer to this, but am getting a lot of conflicting and confusing info. I know there is no one pat answer for all beers, but are there some guidelines for the amount of O2 to add to your wort before pitching yeast?

I'm getting an inexpensive O2 regulator from a brew shop. I plan to hook up an inexpensive flow meter so I can measure out how much I'm adding. But I'd kind of like to know what others are doing.

I'm getting an inexpensive O2 regulator from a brew shop. I plan to hook up an inexpensive flow meter so I can measure out how much I'm adding. But I'd kind of like to know what others are doing.