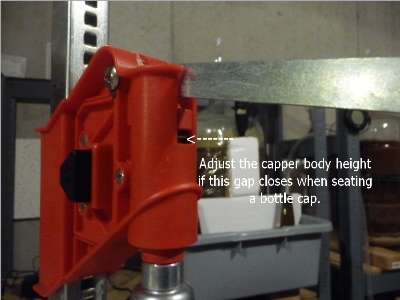

Yes I looked through quite a few pages on capping but this never really was addressed. I use an Agata bench capper and the caps push hard and then seem to slip into place. Do I push down then real hard or since it has already seated and feels like the bell has slid down is it good enough?

That's something they never really explain. Has it crimped in once the bell has slid over? I put small dents/smiles in a few caps and think I was pushing too hard.

That's something they never really explain. Has it crimped in once the bell has slid over? I put small dents/smiles in a few caps and think I was pushing too hard.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)