CharlieVT

Active Member

- Joined

- Aug 25, 2020

- Messages

- 32

- Reaction score

- 20

I'm sure others have posted about this, but I wanted to share my experience.

I picked up the pull through tool and fittings from BrewHardware.com.

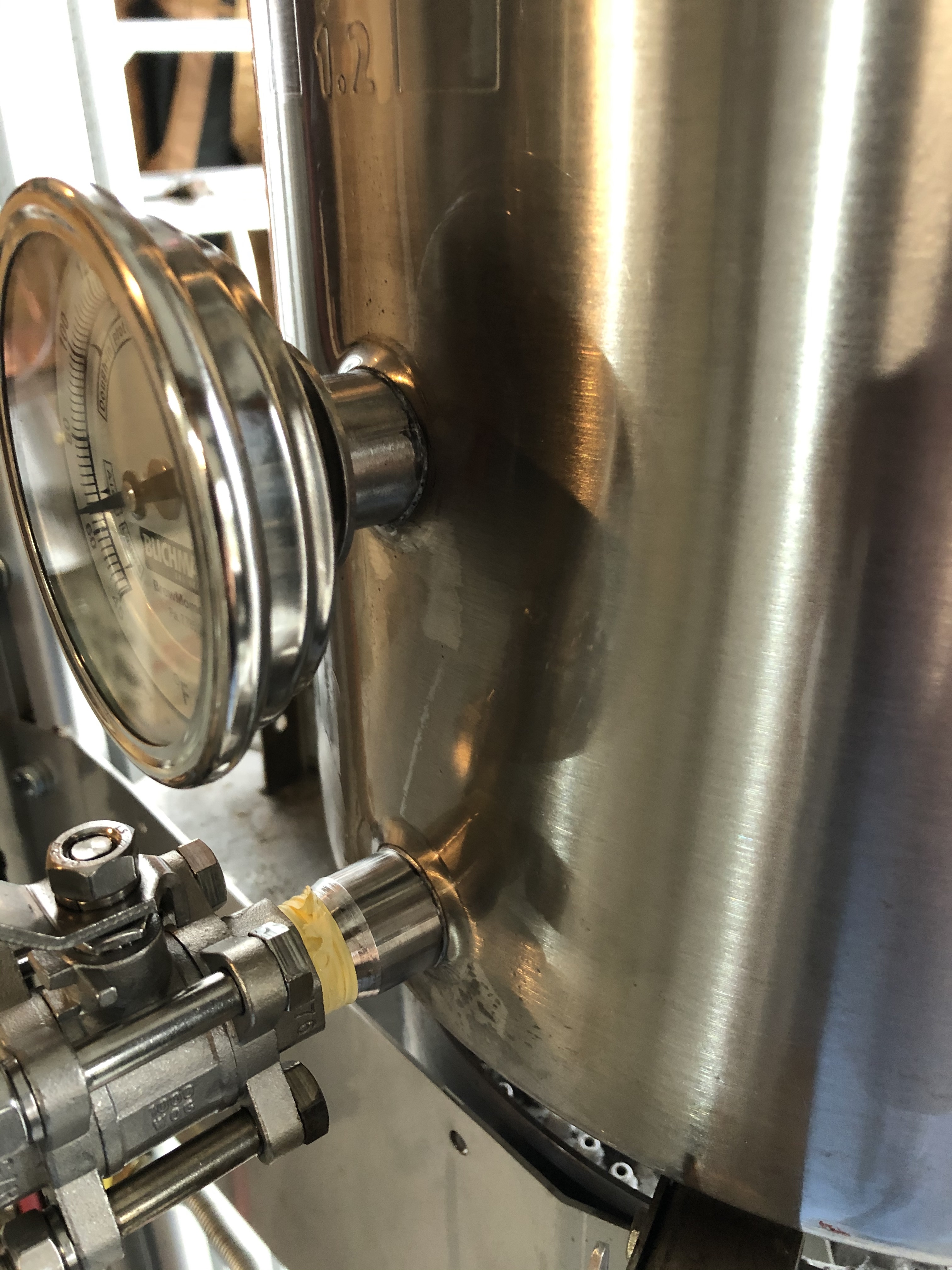

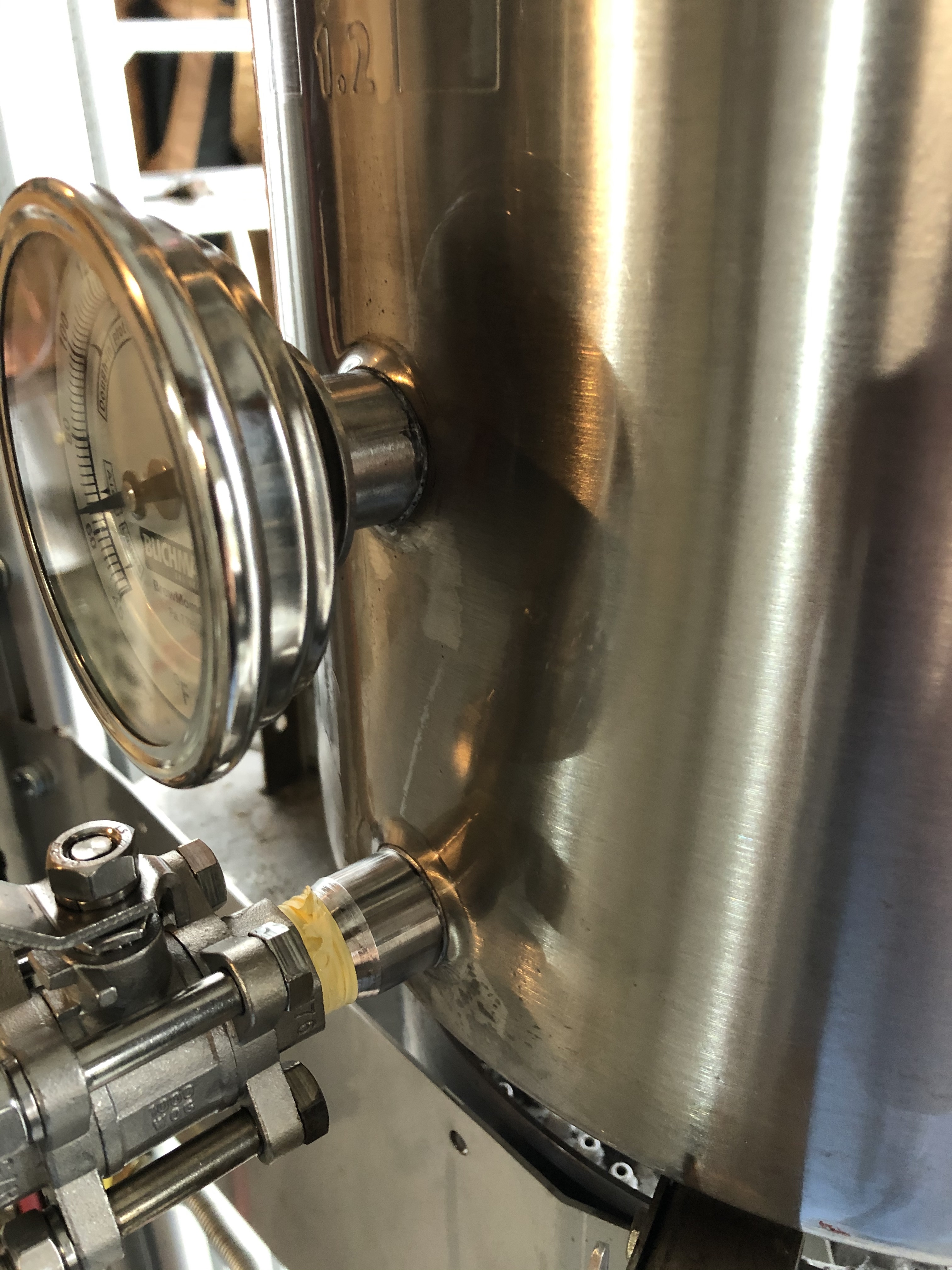

I have three megapot 1.2 kettles, all that I purchased used. The gasketed weldless fittings were a pain in the neck, and I struggled with leaks, some worse than others.

In preparation, I used a thermometer bung as a form to create coils with two wraps. I had six fittings to install, and only had enough from the first coil of silver solder to make five sets. Luckily I purchased an extra section of silver solder.

I used a deburring tool on all of the holes, then sandpaper to smooth the inside of the holes. I cleaned them with acetone, then used map gas to heat around the holes. I let it cool down (hopefully annealing, but I know nothing about metallurgy).

Once it was cooled, I cleaned again with acetone, used the flux to lubricate the fittings and used the pull through tool to insert them. I used the tapered fitting to pull the thermometer bung tapers, knocked them out with a dead blow hammer (be careful!!) then pulled the thermometer bungs in (making sure the narrow side of the taper was inside), then did the same with the drain fitting. I used flux for pulling lubricant as directed.

Then I hung the pots (one at a time) on a bracket hung from my ceiling with the fittings on the bottom side. I added more flux to each fitting, then carefully heated the pot arround the fitting, then moving the heat to the fitting itself until the solder melted into the taper.

After cooling, I cleaned it up with Barkeepers Friend and it was good to go.

This was a HUGE upgrade, removing a bunch of connections, fasteners and places to clean. I'd highly recommend it to anyone. If you have the skill level to solder copper pipes, you can do this job.

The one thing I wished for was a better way to center the thermometer bungs, since I got some of the tapers slightly off center. Fully functional, just not as pretty. The drain fittings were centered well.

I picked up the pull through tool and fittings from BrewHardware.com.

I have three megapot 1.2 kettles, all that I purchased used. The gasketed weldless fittings were a pain in the neck, and I struggled with leaks, some worse than others.

In preparation, I used a thermometer bung as a form to create coils with two wraps. I had six fittings to install, and only had enough from the first coil of silver solder to make five sets. Luckily I purchased an extra section of silver solder.

I used a deburring tool on all of the holes, then sandpaper to smooth the inside of the holes. I cleaned them with acetone, then used map gas to heat around the holes. I let it cool down (hopefully annealing, but I know nothing about metallurgy).

Once it was cooled, I cleaned again with acetone, used the flux to lubricate the fittings and used the pull through tool to insert them. I used the tapered fitting to pull the thermometer bung tapers, knocked them out with a dead blow hammer (be careful!!) then pulled the thermometer bungs in (making sure the narrow side of the taper was inside), then did the same with the drain fitting. I used flux for pulling lubricant as directed.

Then I hung the pots (one at a time) on a bracket hung from my ceiling with the fittings on the bottom side. I added more flux to each fitting, then carefully heated the pot arround the fitting, then moving the heat to the fitting itself until the solder melted into the taper.

After cooling, I cleaned it up with Barkeepers Friend and it was good to go.

This was a HUGE upgrade, removing a bunch of connections, fasteners and places to clean. I'd highly recommend it to anyone. If you have the skill level to solder copper pipes, you can do this job.

The one thing I wished for was a better way to center the thermometer bungs, since I got some of the tapers slightly off center. Fully functional, just not as pretty. The drain fittings were centered well.