skraeling

Scientist Extraordinaire

- Joined

- Sep 26, 2013

- Messages

- 721

- Reaction score

- 285

Keeping the lid on will hamper the release of DMS during the boil and may lead to off flavors.

Sure other this having been proven false already.

Keeping the lid on will hamper the release of DMS during the boil and may lead to off flavors.

Sure maybe if lid was metal and completly covering the unit not allowing any steam escape, then I could see that.

But keeping the lid partially on that even has a hole I doubt would hamper the driving off of dms.

Sure other this having been proven false already.

It comes down to degrees. DMS is more a concern with Pilsner malts, and to what degree the condensation which contains the DMS returns to the wort. Also how sensitive you are to DMS off flavors. How much steam condenses and returns vs how much escapes through that small hole....

You don't need to have a volcanic boil going. A constant rolling boil is plenty.

Where have you seen that this has been proven false?

The experimental brewing guys im pretty sure debunked the whole dms/lid thing in one episode.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Just received my Grainfather and am unpacking / assembling and have a question. There is a 2.5-3" wide strip of what appears to be yellow sheet fiberglass curled around the inside of the kettle just above the pump inlet. Is this just packing material?

I don't think so, but if you have a link....

The Brulosophy guys just did this one, was proven false in their experiment at least;

http://brulosophy.com/2016/10/31/the-boil-lid-on-vs-lid-off-exbeeriment-results/

They also did a 30 min boil with pilsner malt, ended up with no DMS;

http://brulosophy.com/2015/09/14/boil-length-pt-2-pilsner-malt-exbeeriment-results/

No it wont.

The Brulosophy guys just did this one, was proven false in their experiment at least

Agreed. Nothing Brulosophy does is conclusive, but perhaps it's enough to make one question homebrewing dogma? My biggest takeaway from those experiments is that what we learn as absolute truth may not be absolute.

I'm waiting for their response. No, not on a GFI abut will be now. Yeah, no idea why it did that. I do hope they replace it.

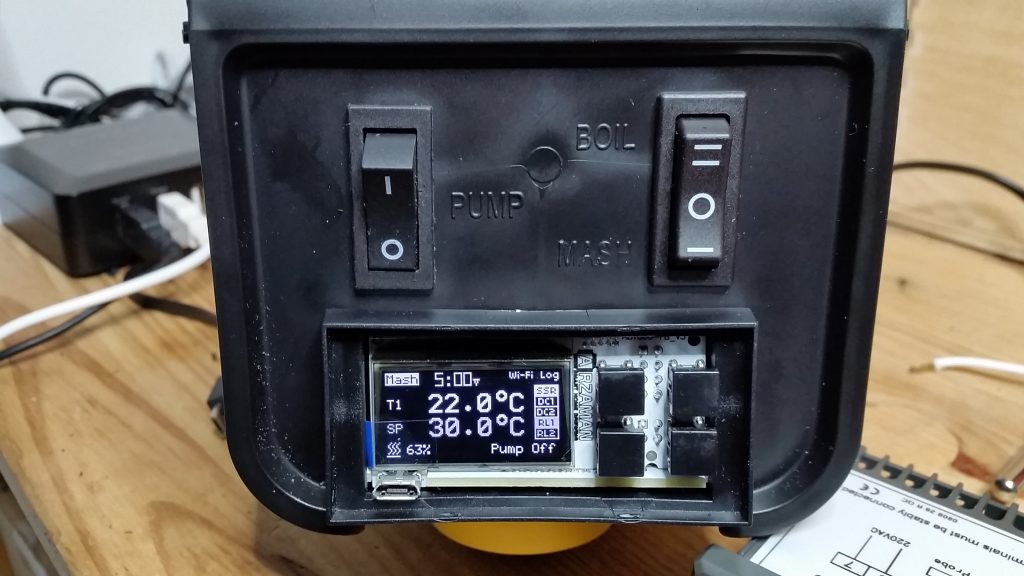

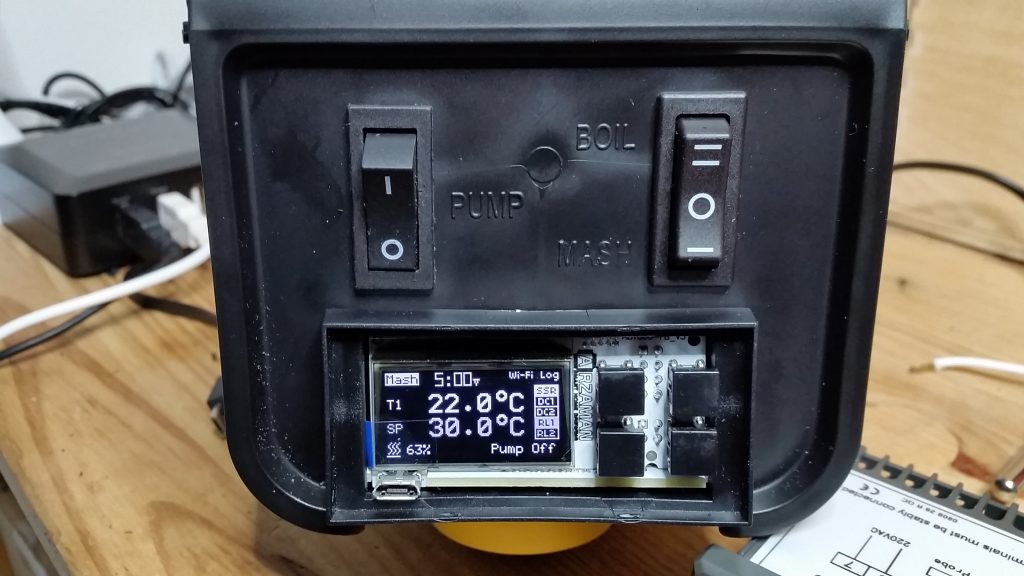

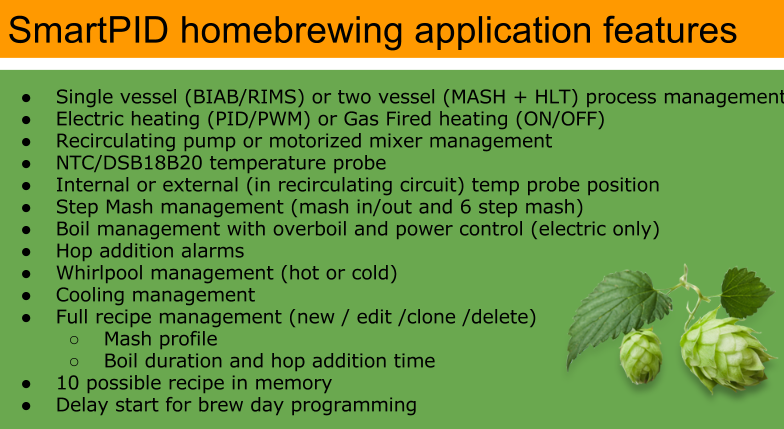

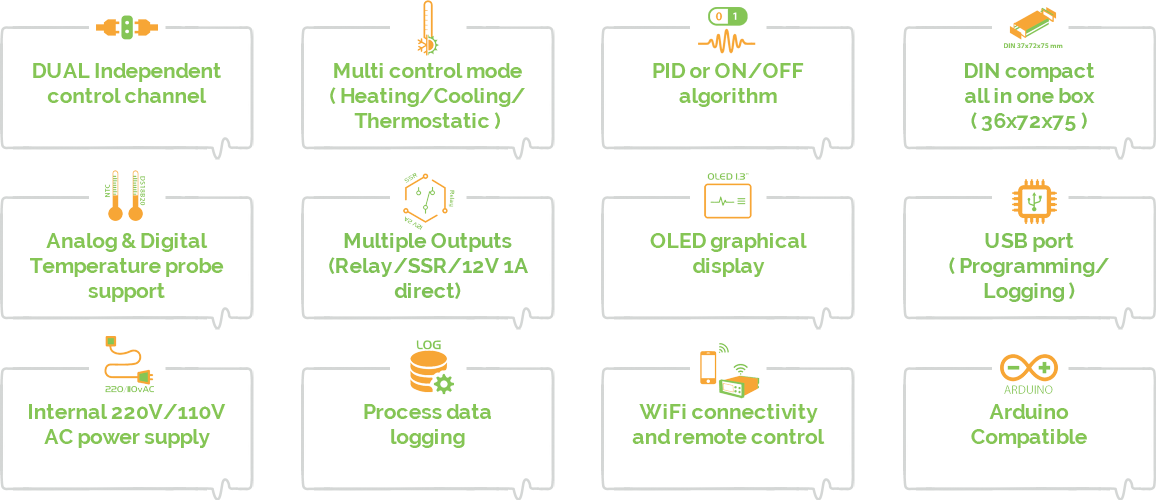

Working to a plug-n-play and easy retrofit solution to upgrade original grinfather controller with Smartpid and need some suggestions and ideas from GF community

The idea is to keep the original case and switches, just removing STC200 and rewiring Smartpid in order to get full process automation, recipe management, wifi data log, OLED graphical display, USB, etcetc.. and basically there a two options

1) connect heating element to relay 1 , connect pump to relay 2 in parallel to switch, connect temperature probe to one of the two control channel. Just two wires for pump and a screw driver !

You can benefit all the smart PID automation feature (including pump cycle automation) but the temperature control during step mash will be performed ON/OFF (with hysteresis) since is not advisable to use PID /PWM algorithm with mechanical relay output

Also during boil you lose the nice feature to control power via PWM 0-100%

2) insert in the case a solid state relay (10A minimum) to control heating elements, pump control and temperature probe as option 1

Little bit of extra work and a need of suitable SSR with heat sink to fit in the small spare space inside the case but you can benefit full PID + PWM solution either in mashing or in boiling

there is also a 3rd option more invasive that need to work on the base of GF separating 2 heating element now in series in order to control them separately (500W by PID during mashing, 1500 W by relay during mash in/out and boil)

what option do you prefer ? Any other suggestion ?

arzaman

http://smartpid.com

I'm thinking the horse is out of the barn here...GF is releasing a simple plug and play controller upgrade that will do what most people here want/care about - if they choose to upgrade at all. Could this arduino unit be cheaper and more easily controllable than the GF unit? Possibly more tweakable but at the end if the day, it will boil down to price/timing and I know where my money's going. Not wanting to be a party pooper though! :-0

Hi

I didn't run a full feature comparison with the new controller upgrade from GF (I see just some video preview) and for sure I expect they did a great job either on the HW and the SW also become they come after a series of other aftermarket controllers...so they have time to study

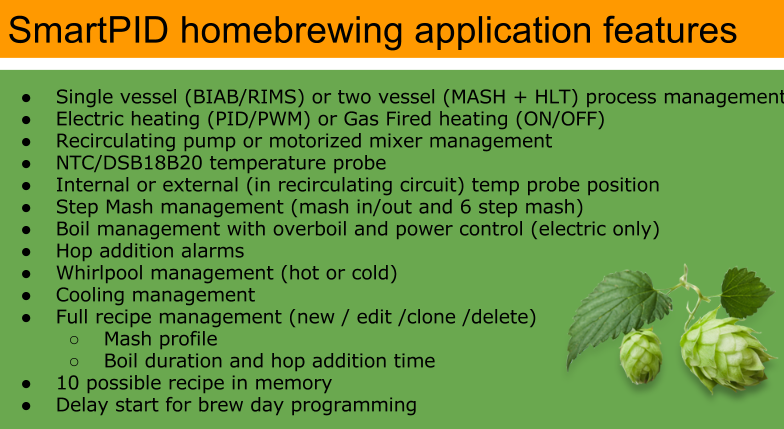

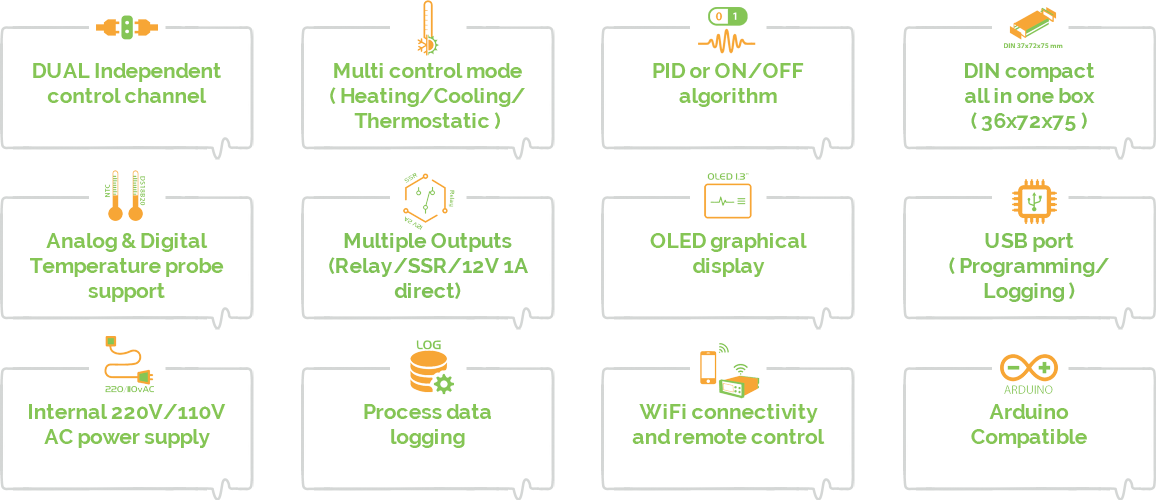

In term of feature and functions I suggest to have a look to SmartPID web site and also to some video done with simulator that provide you full picture on how the brewing process has been automated in all details.. I think there are some feature like data logging either via USB or via web/smartphone, recipe management etc.. that could make the difference

SamrtPID moreover is no just brewing process automation...is a multi-application platform and you can install an run a smart thermostat for thermostatic control of you fermentation chamber etc. etc..

SmartPID is not and arduino DIY kit is a ready made PRODUCT..It has been designed by a maker and diy enthusiast for the maker and homebrewer community so by definition is tweak and programmable and is off course 100% arduino compatible

About cost...working hard with manufacturer to kee it affordable for consumer and DIY market...It will no cheap as STC1000 but it will not cost a fortune like Siemens PLC

enjoy

arzaman

Ya big down fall of the grain father is blockage. I've learned my lesson the hard way already... make sure your whirlpooling for a couple minutes after the boil when the wort is still hot to get a nice tight trub cone in the middle. I use a hop spider for my pellet hops or you could go the cheaper route and get a couple of paint strainer bags from homedepot/lowes and use those. I may actually switch back to strainer bags since my disappointed in my spider right now.Did a bit of searching and this may very well be in the massive thread somewhere but didn't see it.

After my boil I turned the pump on to recirculate for 10 minutes to sanitize the chiller. Heard some air going into the wort and then it plugged. Could see a chunk of stuff in the clear tubing of the recirculation arm. Took the arm off to try and shake it out, put it back on still plugged. Squeezed the tubing and turned the pump off and on and managed to get it unplugged. Suppose I could just have rinsed out the recirculation arm but didn't want to introduce tap water to it at that point - guess it was still hot enough to kill anything. Once it was unplugged all was fine including subsequent transfer.

Anyway, felt I got lucky this time but I am wondering if anyone has any tips on how to deal with a blockage say in the chiller itself (or generally from the filter and up). Only had 4 oz. of hops in this batch.

Thanks!

Ya big down fall of the grain father is blockage. I've learned my lesson the hard way already... make sure your whirlpooling for a couple minutes after the boil when the wort is still hot to get a nice tight trub cone in the middle. I use a hop spider for my pellet hops or you could go the cheaper route and get a couple of paint strainer bags from homedepot/lowes and use those. I may actually switch back to strainer bags since my disappointed in my spider right now.

Be careful not to hit the pump filter when whirlpooling. . It's easy to detach. I have the filter off several times.

Do you mean that when you set the temp the element isn't turning on and heating up? If so there is a reset button underneath the unit. Just flip it on it's side and hold it down for a couple seconds.So I set up my grainfather last night for first cleaning and the set button on the temperature controller doesn't seem to work. I can hold it down as long as I like and nothing happens. I tried holding the up and down arrows to see if I could get any reaction and no luck there either. Temp shows fine and changes appropriately. It is a US version. Is there some way to reset the controller or something? Anyone else had this issue? I have sent a note to grainfather as well.