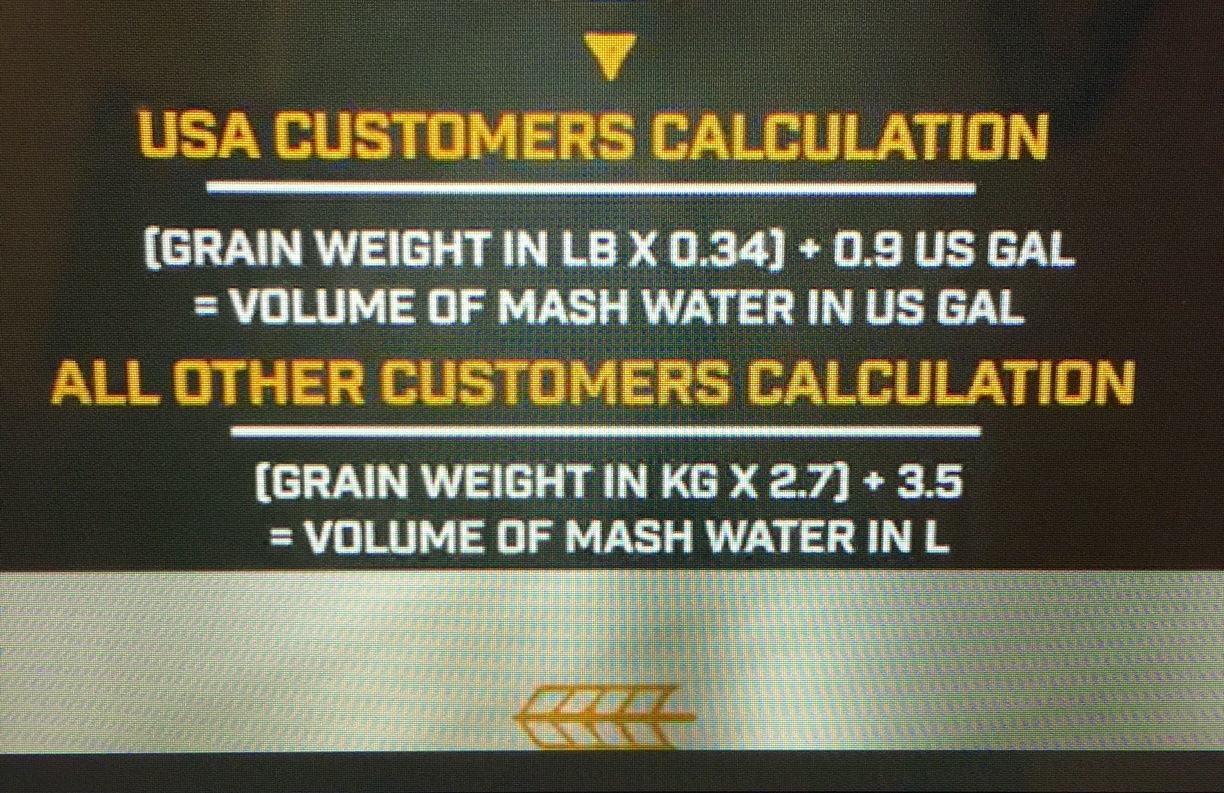

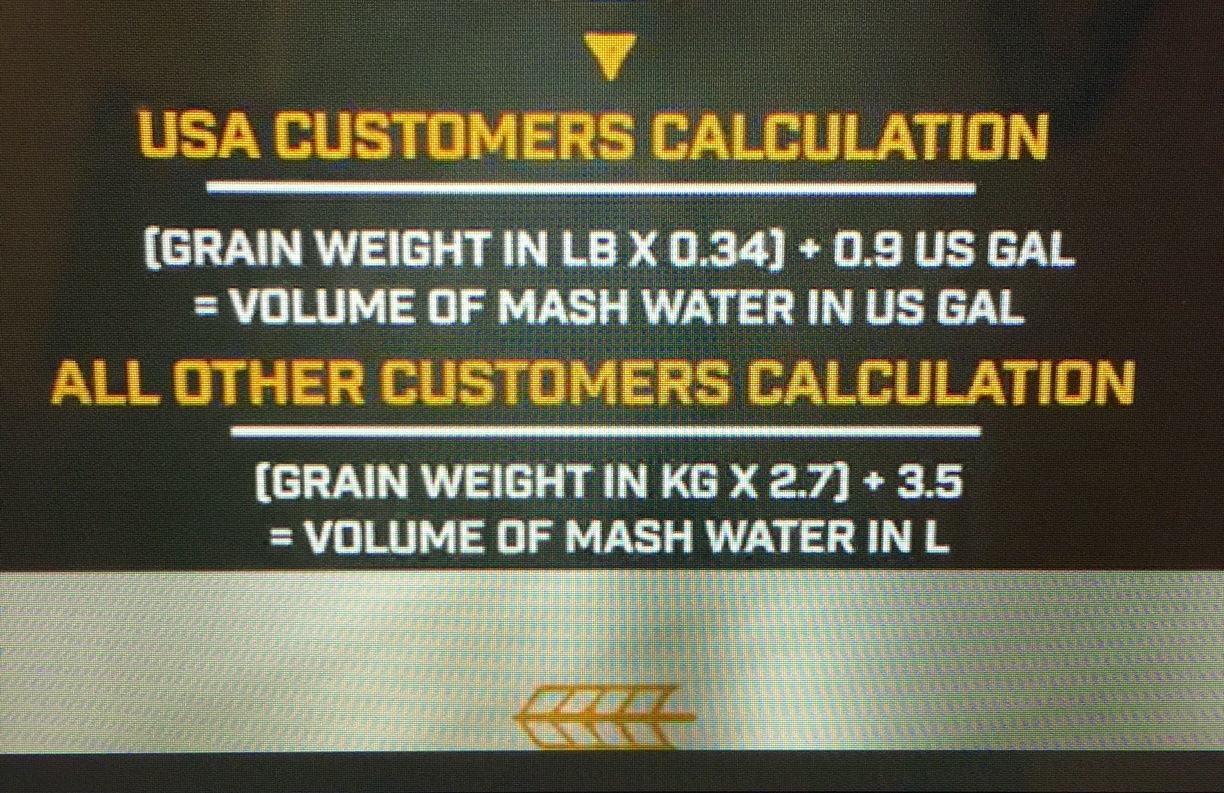

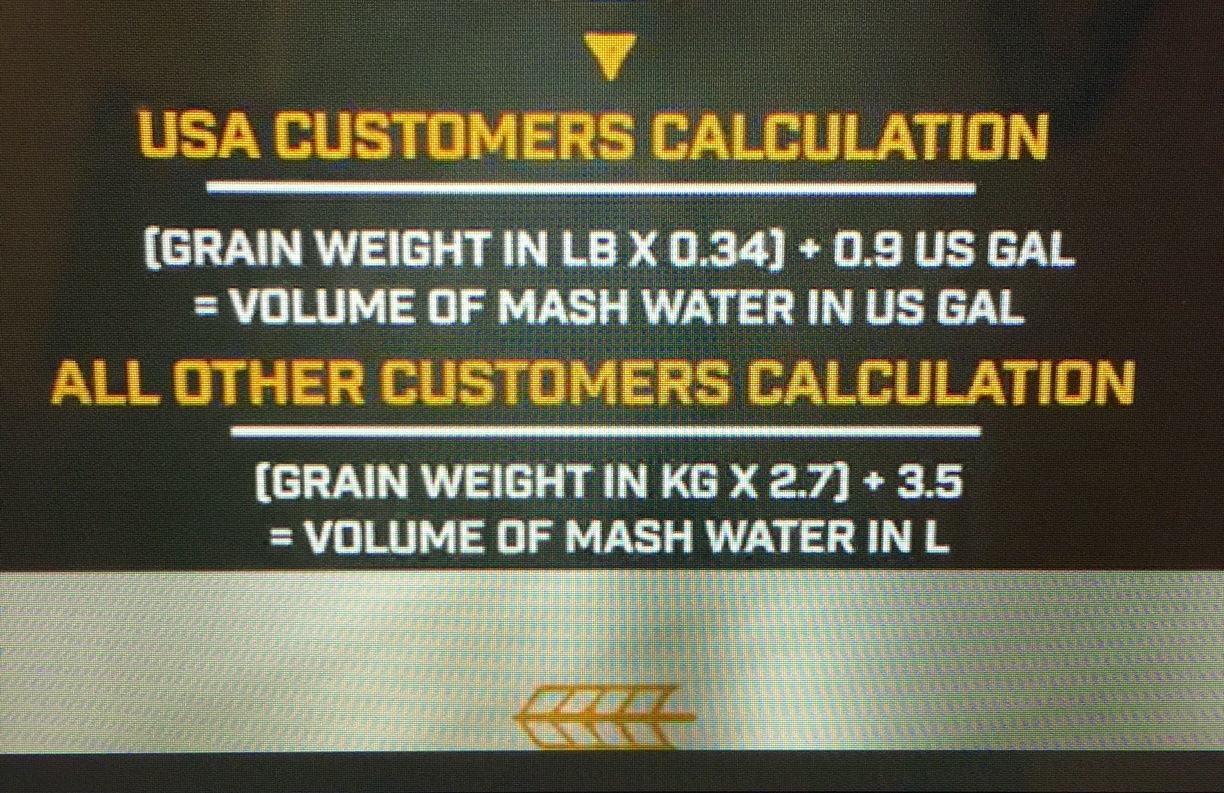

Also, here's a couple of screen shots on how to calculate your mash and sparge water.

The standard in the food industry for sanitizing is 77c/170f

I've used up to 6 ounces of pellet hops. Posted a video a while back in the thread of someone using 8 ounces of pellet hops, neither of which clogged, both mine and his are throwing the hops directly into the boil.

Was it slow on the transfer to the fermenter? Absolutely. I just use that time to clean everything I can that isn't being used at the moment.

I was going to try taking the spring and ball out during the transfer to see if that helped, but haven't done that yet.

I have a 300 micron 6x14 hop screen I used to use. I'm not excited about my wort inside the screen not boiling while everything outside the screen is. Mine never clogged, I just feel better not using one. as others have mentioned, if you really want to use one, go with the 400 micron.

yep, same here use the time for cleaning, I removed the spring and ball several batches now and no speed up on transfer that I notice.

I removed the ball and spring too. If anything, it seems even slower, like the pump had more suction and is able to compact the trub around the filter even tighter

I removed the ball and spring too. If anything, it seems even slower, like the pump had more suction and is able to compact the trub around the filter even tighter

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I removed the ball and spring too. If anything, it seems even slower, like the pump had more suction and is able to compact the trub around the filter even tighter

I'm in. Placed the order this afternoon with Northern, then had to get the coat directly from Grainfather since Northern didn't carry it! (boo).

Hopefully I'll be able to play with my new toy this weekend!

Yes, there is a simple mathematical formula in the user manual to derive your exact quantities of both mash and sparge water. .... Worked out nicely. . ..

Does anyone know the recommended hop basket size/micron for the Grainfather? Searching reveals lots of discussion, but no sizes/products to buy.

Well damn it, never thought of that.

Do you think I need to clean the wort chiller or just switch to cold water?

Anybody used leaf hops with the GF? How'd it do? ... At one point I had my wife lift up the chiller while I scraped the filter with a spoon, which helped a bit, but soon slowed again. I'm considering moving the chiller off the top of the unit in the future so I can scrape the filter constantly while transferring.

I think I found another use for the Grainfather. I heat sanitized some keg parts tonight. With my propane burner I didn't use heat to sanitize anything because I didn't want to melt any rubber or plastic parts. I put the keg parts in the basket and set the temperature controller to 65c and recirculated. 30 minutes should be enough at that temperature. The keg had an infection that I was worried might stick around after PBW and starsan. This gives me a little more peace of mind.

yep, same here use the time for cleaning, I removed the spring and ball several batches now and no speed up on transfer that I notice.

I always run with my chiller on a stool, instead of the lid, so I have access to the boiler.

Here is what I got for sparging.

http://www.amazon.com/dp/B00004RC6S/?tag=skimlinks_replacement-20

I went with the used option from amazon for $60.

an Inkbird controller and it has been great.

I have a thermowell and ball valve that I am in the process of installing then I'll be done.

Great idea! I'm thinking this might be the way to go for me in the future so that I can scrape the trub off the filter periodically. I agree that it's a great time for cleaning during the transfer, but I'm not built for multitasking. I want the wort in the fermentor ASAP so I can devote my attention to something else. Personal hangup, I guess.

I doubt it ..... most of these manufacturers use anywhere from 3 or 4 ounces per cup to 5 or 6 ounces per cup. I went to a restaurant supply website, and West Bend's 101 cup urn is 3.9 gallons.Ohh yea this looks way awesome! It just says 100 cups of coffee. Im guessing thats the standard us cup so over 6 gallons?

The first time that happened it plugged up the filter so bad the water wouldn't even come out of the faucet. We just finally dumped the filter and now we go to another town and get really good mountain water from a spring -Sorry to hear about your crappy water. That sounds pretty bad. I have a sediment prefilter on my RO unit, and it's entertaining to watch it turn from white to orangish-brown over the course of a couple months use.

Still working on thatGood luck on deciding on a system. ..

Not yet! There are you tube videos you can see on this topic from GF.I have read a fair bit of the thread, but not all. I have not seen anybody discuss using the still, anybody tried?

You got it, stir! That's all, no boil over. If you keep the lid on to get up to boil it will try to boil over so just remove lid as you approach 212....Probably on here but how to stop boilovers? Wort hardly ever tries to boil over for me but I usually just remove the pot from the stove, stir a bit then back on...

Sounds good for drinking but I'd still want to know it's profile. I've gotten more into water adjustment, Bru'n water, and I believe it makes a big difference. Especially on light color brews...get really good mountain water from a spring

Probably on here but how to stop boilovers? Wort hardly ever tries to boil over for me but I usually just remove the pot from the stove, stir a bit then back on.

How quickly does this heat up? Maintains a good temp with the PID?

Honestly, I haven't paid much attention to heating time.

I start it up when I am almost ready to mash in, and it's always ready when I sparge.

According to this site: http://www.jesrestaurantequipment.c...-capacity-polished-aluminum-fin-p-935381.html

It holds 4.68 gallons.\

It seems to keep the temp pretty well.

I'll see once I get the thermowell installed how that affects things.

Right now I have my probe just hanging in the water.

Just got my own Grainfather, can't wait to try it! This thread as been really helpful!

Yeah, I got the readout from the city ..... the water is so pure in that town the EPA can't force the Chlorine/Chloromine/Flouride crap on them but the city told me that the EPA forces them to "clean the delivery system (pipes)" once a year, so they have to warn all the users not to use the water for 2 weeks until the chemicals have disappeared from the water! It's great water! -- Annnnd, I usually only make Dark beers and very hoppy IPAs. As we all know, "A Hoppy Beer is a Happy Beer!" I see you're enjoying your GF .... congrats!Sounds good for drinking but I'd still want to know it's profile. I've gotten more into water adjustment, Bru'n water, and I believe it makes a big difference. Especially on light color brews

Honestly, I haven't paid much attention to heating time.

I start it up when I am almost ready to mash in, and it's always ready when I sparge.

According to this site: http://www.jesrestaurantequipment.c...-capacity-polished-aluminum-fin-p-935381.html

It holds 4.68 gallons.\

It seems to keep the temp pretty well.

I'll see once I get the thermowell installed how that affects things.

Right now I have my probe just hanging in the water.

Honestly, I haven't paid much attention to heating time.

I start it up when I am almost ready to mash in, and it's always ready when I sparge.

According to this site: http://www.jesrestaurantequipment.c...-capacity-polished-aluminum-fin-p-935381.html

It holds 4.68 gal

I was actually just about to order one. But 4.68 gallons seems like not enough to me, although I am not on the grainfather for a couple more weeks. I guess Ill wait and see how much water I end up sparging with, my 8 Gallon pot and 10 Gallon Cooler mash tun should work just fine.

Question. I know it is silly but I still use my original spinning flysparge arm on my regular AG batches. It does not disturb the grain bed at all and thats why I keep using it. Is it possible to use it on the grainfather? Any thoughts?

If you use BrewSmith to develop your recipes, it will assist in establishing the right strike water temperature by entering the grain temperature in the mash profile. I've found it does a rather good job providing you have changed some settings in BeerSmith to fit the Grainfather. Use the attached profiles and explanation to make the necessary changes. By the way, by making these changes, BrewSmith's inability to accurated calculate mash and sparge water quantities are also fixed

I see you are even a bit farther north than I am... so we are dealing with similar temperatures.

What kind of volumes are you typically working with? And, do you find that the reflectix provides any benefit, or no?

5.5g in the fermenter, I don't do huge beers so no monster grain bills.

Mostly I think it helps speed up heating time, probably helps maintain mash temp better so heater is firing less, reducing scorching.

Keep in mind you're not gonna get a raging volcano boil like a gas burner, you get a rolling boil, which is all you need. Also means less boil-off, so less steam and humidity output when you are brewing inside.

A dedicated 20 amp circuit with no extension cord may be more important, based on what I've read on this thread. That's what I have. You need every watt you can get from the element when it's colder!