mistercameron

Well-Known Member

FRIDGENSTEIN

Synopsis: I'll show you how I took a craigslist refrigerator and turned it into a rockin side-by-side kegerator and fermentation chamber using some inexpensive controllers, a little bit of know-how, and a whole lotta elbow grease.

You need to be comfortable with things that can cut plastic and metal, and you have to be comfortable with wiring electronics. It's basic and not hard to learn, but this might be a bit confusing if this project is your learning material. Above all, be patient and plan it through. Know what you're going to do before cutting.

-------

I've been working on this build for the last couple months, and though it's not 100% done, it's 100% functional. I got most of my information and inspiration from three threads:

Side-by-Side Kegerator/Fermentation Chamber, by Forbein11

Sibe By Side kegerator/fermenting chamber conversion, by rtrevino

ebay aquarium temp controller build, by android

-------

Here's a "Done" version of fridgenstein so reading this thread is worthwhile

First things first... locating the fridge. Do your research. I think both Forbein and rtrevino both have Frigidaire side-by-sides. I did some digging and found out that similar looking Kenmore fridges are made by the same manufacturer. The similarities are uncanny. I was willing to spend up to $100 on the fridge so I started visiting craigslist frequently. After a week or two, the fridge I wanted showed up in a listing. It had a bunch of broken shelves, so I talked the seller down to $50. It smelled like a bait shop. Don't worry - nothing a few applications of a good strong bleach solution can't take care of. I was told this one was about 10-11 years old, so roughly a 2000/2001 ANALOG controls model. Make sure it's analog that the controls are dials, not some kind of LCD+button display - it's vitally important.

What does the fridge look like? Well, I thought I had photos from the early parts of the build, but I don't after all. See the photos from the above threads. The inside of my fridge looked identical in every way. It will be easiest on you if you get something like the ones you're seeing here, though it's not impossible to set up your own controller rig.

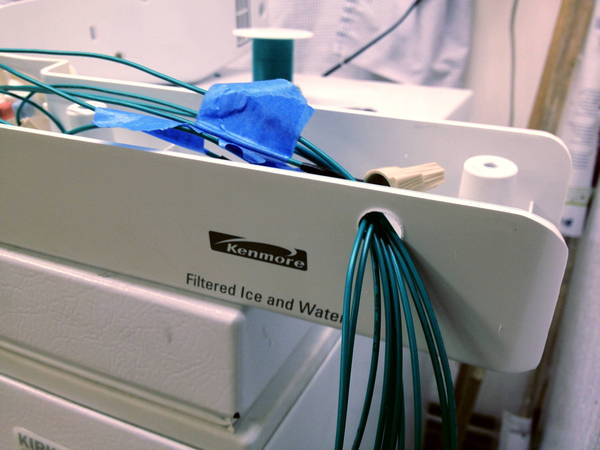

Take it all apart: If a part could reasonably be unscrewed and taken off, I did. I used a strong bleach+vinegar solution (add 1oz of regular bleach to 5gallons of water, then add 1oz of white vinegar) to spray and wipe down every surface that was going to end up anywhere near the beer. This included removing the shelves, water filter, the control panel in the fridge, the wire racks, ice maker, the back sheet metal paneling in the freezer... everything. I got it all dripping wet with the bleach solution and let it air dry overnight. I did the same thing the next day with starsan. Only the necessary items made it back into the final fridge. It wasn't much.

Take note: One reason I took photos was to document what parts went where. Once you spend time around it you'll get more comfortable.

Synopsis: I'll show you how I took a craigslist refrigerator and turned it into a rockin side-by-side kegerator and fermentation chamber using some inexpensive controllers, a little bit of know-how, and a whole lotta elbow grease.

You need to be comfortable with things that can cut plastic and metal, and you have to be comfortable with wiring electronics. It's basic and not hard to learn, but this might be a bit confusing if this project is your learning material. Above all, be patient and plan it through. Know what you're going to do before cutting.

-------

I've been working on this build for the last couple months, and though it's not 100% done, it's 100% functional. I got most of my information and inspiration from three threads:

Side-by-Side Kegerator/Fermentation Chamber, by Forbein11

Sibe By Side kegerator/fermenting chamber conversion, by rtrevino

ebay aquarium temp controller build, by android

-------

Here's a "Done" version of fridgenstein so reading this thread is worthwhile

First things first... locating the fridge. Do your research. I think both Forbein and rtrevino both have Frigidaire side-by-sides. I did some digging and found out that similar looking Kenmore fridges are made by the same manufacturer. The similarities are uncanny. I was willing to spend up to $100 on the fridge so I started visiting craigslist frequently. After a week or two, the fridge I wanted showed up in a listing. It had a bunch of broken shelves, so I talked the seller down to $50. It smelled like a bait shop. Don't worry - nothing a few applications of a good strong bleach solution can't take care of. I was told this one was about 10-11 years old, so roughly a 2000/2001 ANALOG controls model. Make sure it's analog that the controls are dials, not some kind of LCD+button display - it's vitally important.

What does the fridge look like? Well, I thought I had photos from the early parts of the build, but I don't after all. See the photos from the above threads. The inside of my fridge looked identical in every way. It will be easiest on you if you get something like the ones you're seeing here, though it's not impossible to set up your own controller rig.

Take it all apart: If a part could reasonably be unscrewed and taken off, I did. I used a strong bleach+vinegar solution (add 1oz of regular bleach to 5gallons of water, then add 1oz of white vinegar) to spray and wipe down every surface that was going to end up anywhere near the beer. This included removing the shelves, water filter, the control panel in the fridge, the wire racks, ice maker, the back sheet metal paneling in the freezer... everything. I got it all dripping wet with the bleach solution and let it air dry overnight. I did the same thing the next day with starsan. Only the necessary items made it back into the final fridge. It wasn't much.

Take note: One reason I took photos was to document what parts went where. Once you spend time around it you'll get more comfortable.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I look forward to seeing the result

I look forward to seeing the result