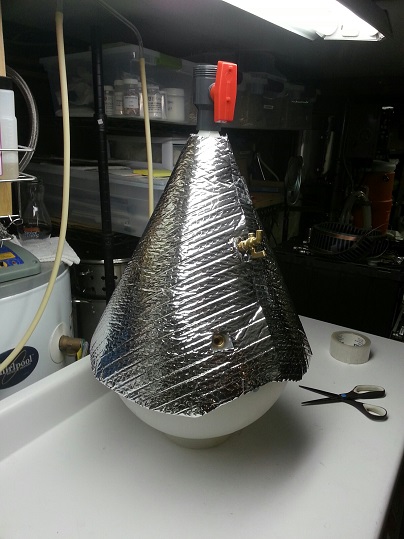

If anyone is having issues with leaking (JAG107?) from the union valve (not the threads that attach it to the bottom of the conical, but the joint on the bottom of the valve) check the valve itself.

The valve ball (the part that rotates inside) is tightened down with a threaded ring inside on the bottom of the ball that pushes up and creates a tight seal.

This insert piece can unthread when you loosen the outer ring when removing the ball, especially if you rotate the ball to unthread it . I opened mine and found this piece to move very easily.

Put some Teflon tape on its threads to stiffen it and it seems ok once seated. (must be done with empty vessel)

If you grab the red handle and feel any side to side play, this is the issue. Mine loosened so much that it was a steady stream flowing out the ball valve when it was in the closed position.

A key to remember is to keep the collection ball from rotating and only loosen the ring when removing.

The valve ball (the part that rotates inside) is tightened down with a threaded ring inside on the bottom of the ball that pushes up and creates a tight seal.

This insert piece can unthread when you loosen the outer ring when removing the ball, especially if you rotate the ball to unthread it . I opened mine and found this piece to move very easily.

Put some Teflon tape on its threads to stiffen it and it seems ok once seated. (must be done with empty vessel)

If you grab the red handle and feel any side to side play, this is the issue. Mine loosened so much that it was a steady stream flowing out the ball valve when it was in the closed position.

A key to remember is to keep the collection ball from rotating and only loosen the ring when removing.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

. Will be testing it out this upcoming weekend

. Will be testing it out this upcoming weekend