Don't know mate, but you losing it looks more like a three year old's behaviour than anybody else in this thread to me.First of all MATE, go back to the #1 post on this thread and you'll see where I got that co-souring method. cut and paste.

I might as well open my own thread. Y'all are acting like a bunch of 3 yr olds. nit-picking mf'ers . if its not 100% worded like you say , its wrong. I'm just done.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fast Souring - Modern Methods

- Thread starter RPh_Guy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

brownni5

Well-Known Member

- Joined

- Dec 17, 2017

- Messages

- 782

- Reaction score

- 337

Belle brings the fg down very quickly so I do not see a chance for oversouring, as there won't be much left for the bacterias to eat, once it is done fermenting.

I'm not sure this will necessarily be the case. LAB, from my experience, can sour without any gravity points, or very little residual sugar, remaining. Just saying I wouldn't count on the Belle to keep the beer from getting overly sour.

SteveH aka shetc

Well-Known Member

- Joined

- Jul 28, 2013

- Messages

- 3,151

- Reaction score

- 5,675

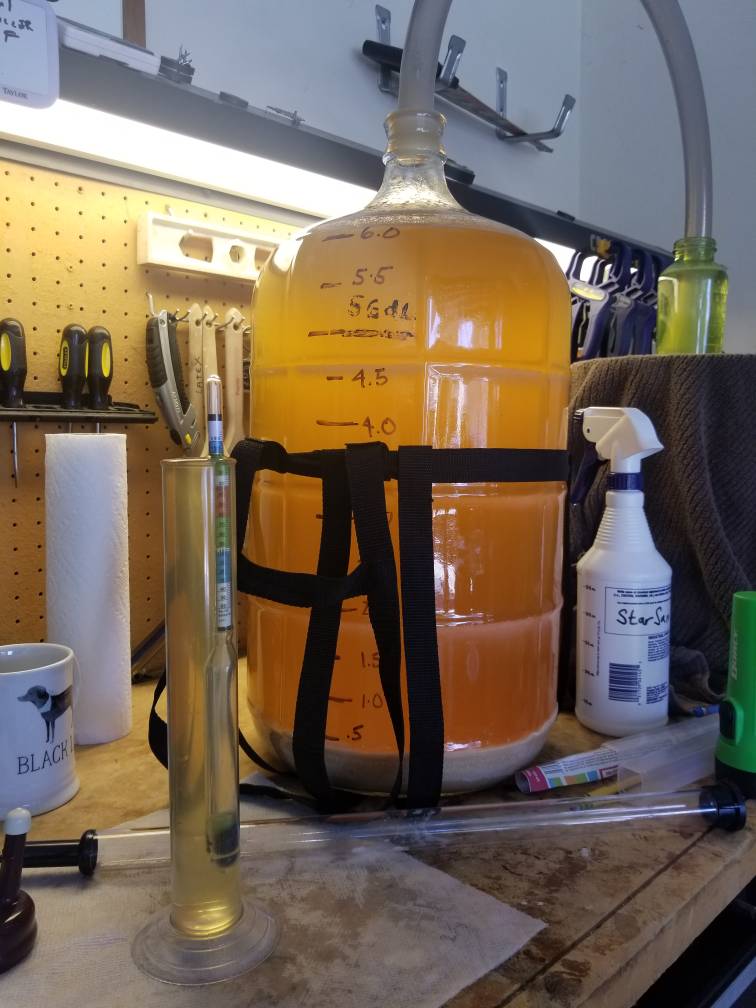

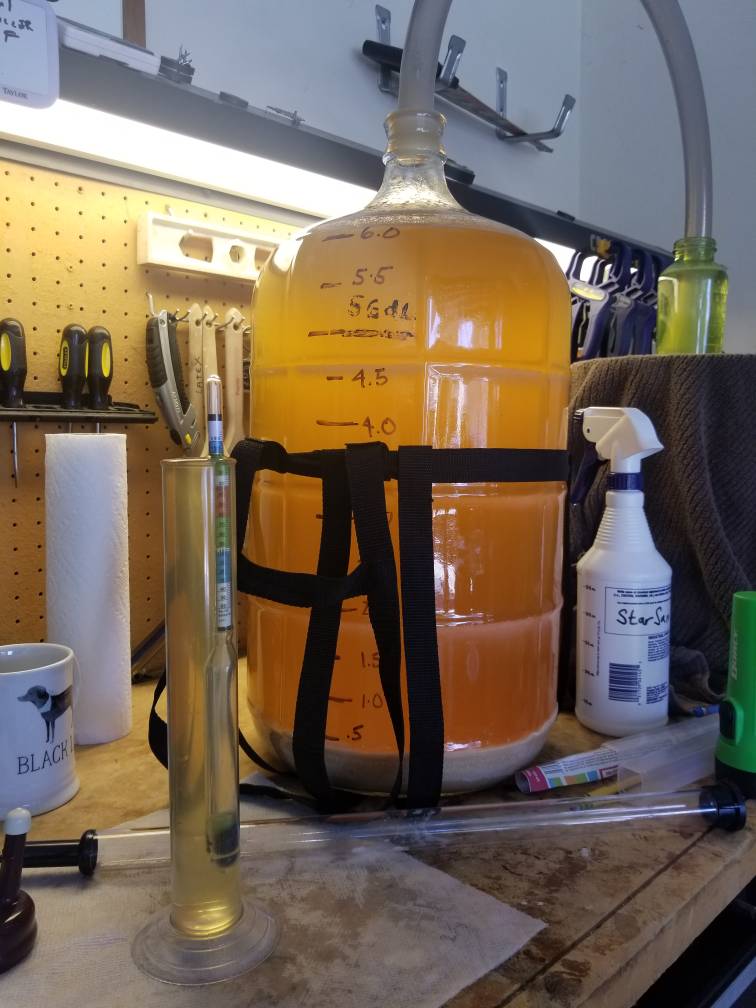

Current gravity of 1.007 & 3.34 pH. Imperial Dieter kolsch flavor coming through very nicely. Going to secondary on fruit today.

I did this once before with a herbal beer without hops and without intentional bacterial additions, those always soured because of the lack of hops. This one did not sour as much as the ones that I made without belle so I think it was because of the lack of sugar. Belle usually gets close to 1.0.I'm not sure this will necessarily be the case. LAB, from my experience, can sour without any gravity points, or very little residual sugar, remaining. Just saying I wouldn't count on the Belle to keep the beer from getting overly sour.

It basically stopped souring once fg was reached.

Last edited:

Here it is! Mango-Pineapple Sour. The tartness goes great with the pineapple finish! Thanks for the help.

FrozenOcean

Well-Known Member

- Joined

- Nov 9, 2013

- Messages

- 107

- Reaction score

- 24

I'm attempting my first sour beer... Followed the OP instructions for co-souring, used two pills of Swanson's L. Plantarum along with US-05.

It's been fermenting for a week now. I have no way to test pH, but it certainly tastes sour now. Gravity is down to 1.012 from 1.055.

My question is: is this likely to sour more? It tastes good, but it I would like it a bit more sour. On the other hand, I'm anxious to get some hops in there... I had an airlock blowout, I had to take my lid off the fermenter to clean things up. I'm nervous about getting it infected with something not so nice.

I didn't get a good sense from reading through this thread how long it would take to finish fermentation.

It's been fermenting for a week now. I have no way to test pH, but it certainly tastes sour now. Gravity is down to 1.012 from 1.055.

My question is: is this likely to sour more? It tastes good, but it I would like it a bit more sour. On the other hand, I'm anxious to get some hops in there... I had an airlock blowout, I had to take my lid off the fermenter to clean things up. I'm nervous about getting it infected with something not so nice.

I didn't get a good sense from reading through this thread how long it would take to finish fermentation.

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

RPh_Guy

Bringing Sour Back

In my experience it can take 1-2 weeks to reach maximum sourness if no hops are added, even though the large majority of souring occurs in the first few days.My question is: is this likely to sour more? It tastes good, but it I would like it a bit more sour.

Effects from contamination are pretty unlikely (though not impossible) from what you've described. Bacteria won't be any problem (i.e. adding hops won't help avoid contamination in this case), and sour beer has extra layers of protection against wild yeast.On the other hand, I'm anxious to get some hops in there... I had an airlock blowout, I had to take my lid off the fermenter to clean things up. I'm nervous about getting it infected with something not so nice.

You if aren't satisfied with the level of sourness, there are ways to increase it for next time, mainly through manipulating the water chemistry.

Beer666

Well-Known Member

- Joined

- Apr 10, 2018

- Messages

- 596

- Reaction score

- 616

How do people go about dry hopping and adding fruit or would i be better adding a hop tea after the fruit has fermented? I have just done a sour wheat beer with Maniacal yeasts Juggernaut kveik blend. About 3 days later i added Omega Labs lacto. Its my best so far, a lot more flavour than co pitching.

RPh_Guy

Bringing Sour Back

I normally add hop tea at the time of packaging. There's no right or wrong answer, but if you want to dry hop, I recommend doing it while fermentation is still active (including the fruit fermentation) in order to reduce oxidation.

FrozenOcean

Well-Known Member

- Joined

- Nov 9, 2013

- Messages

- 107

- Reaction score

- 24

So, I tried to make a hop tea... I had 1 oz of hops boiled in 500mL water for 5 minutes. Then cooled for about 30 minutes by setting the pot in a cold water bath.

Basically what I ended up with was hop paste. I squeezed some liquid out through a strainer, but I'd be surprised if I ended up with more than 100mL of liquid into the fermenter.

Did I do something wrong? More water? Less hops?

Thanks!

Basically what I ended up with was hop paste. I squeezed some liquid out through a strainer, but I'd be surprised if I ended up with more than 100mL of liquid into the fermenter.

Did I do something wrong? More water? Less hops?

Thanks!

Both!!So, I tried to make a hop tea... I had 1 oz of hops boiled in 500mL water for 5 minutes. Then cooled for about 30 minutes by setting the pot in a cold water bath.

Basically what I ended up with was hop paste. I squeezed some liquid out through a strainer, but I'd be surprised if I ended up with more than 100mL of liquid into the fermenter.

Did I do something wrong? More water? Less hops?

Thanks!

RPh_Guy

Bringing Sour Back

I'm not really an expert on hop tea, but that is what I do, and it is pretty thick. I'll take photos and measurements next time. I've had the best results from containing them in a hop sock, squeezing out the liquid and then putting all of it in the beer.I had 1 oz of hops boiled in 500mL water for 5 minutes. Then cooled for about 30 minutes by setting the pot in a cold water bath.

I got an all-stainless French press to help with the straining but I haven't used it for hops yet. It did work reasonably well for some spice teas I made.

Have you had a chance to taste it? You might be surprised how flavorful it is.I'd be surprised if I ended up with more than 100mL of liquid into the fermenter.

First, thanks for starting this thread. I am planning to brew my first sour (probably a Berliner Wiesse, fermented with Voss), and I find your method very approachable for a first-time sour brewer. I do have a couple of follow-up questions:

Just to be 100% clear - is there a certain temp that must be reached, or cleaning/sanitation technique that should be followed? I generally soak my fermenters with 120-130 F tap water and PBW for a while, rinse, then use star san. Is this adequate?

For someone new to sours and not yet confident in my ability to go by taste - is there a recommendation for how to tell when it's "done" using pH or TA? That is, I don't just let it go until it's finished at 3.1-3.3, right? I realize it's more complicated than a single value, I am just hoping that the first one turns out nicely.

Q: Won't the Lacto ruin my equipment or contaminate my other beers?

A: No. Normal cleaning and sanitation procedures easily remove L. plantarum. Furthermore, L. plantarum is extremely hop-sensitive and will not sour your clean beers with hops, even if you directly add it. These techniques actually have LESS risk overall of contamination compared to kettle souring.

Just to be 100% clear - is there a certain temp that must be reached, or cleaning/sanitation technique that should be followed? I generally soak my fermenters with 120-130 F tap water and PBW for a while, rinse, then use star san. Is this adequate?

for the cost of a ph meter i think its a good investment, a sour at 3.2 is far diff then one at 3.4.

For someone new to sours and not yet confident in my ability to go by taste - is there a recommendation for how to tell when it's "done" using pH or TA? That is, I don't just let it go until it's finished at 3.1-3.3, right? I realize it's more complicated than a single value, I am just hoping that the first one turns out nicely.

RPh_Guy

Bringing Sour Back

Great!First, thanks for starting this thread. I am planning to brew my first sour (probably a Berliner Wiesse, fermented with Voss), and I find your method very approachable for a first-time sour brewer.

I've been wanting to make a post-sour with Voss, I think the fresh orange flavor will complement the acidity nicely.

That's good, you'll be fine. I go just a little bit further: I soak my equipment for 24-48 hours with homemade PBW, and then a citric acid rinse (plus water rinses before and after each step). Star San before use.I generally soak my fermenters with 120-130 F tap water and PBW for a while, rinse, then use star san. Is this adequate?

There's not a particular temperature needed; heat just helps the cleaning chemicals work better.

I wouldn't worry about it. Let it finish naturally, and then add hops when packaging. People are generally happy with where it stops on its own, but you can adjust things next time if you want it more or less sour.For someone new to sours and not yet confident in my ability to go by taste - is there a recommendation for how to tell when it's "done" using pH or TA? That is, I don't just let it go until it's finished at 3.1-3.3, right? I realize it's more complicated than a single value, I am just hoping that the first one turns out nicely.

If you're interested in TA levels for comparison, I can test a few of my batches. I don't usually test final pH or TA for beer since it's not really useful for anything. I control mash pH to around 5.4-5.7 and then drop kettle pH to 5.1 toward the end of the boil.

Last edited:

FrozenOcean

Well-Known Member

- Joined

- Nov 9, 2013

- Messages

- 107

- Reaction score

- 24

Have you had a chance to taste it? You might be surprised how flavorful it is.

Great point, I hadn't tasted it! I think either way, I would have wanted a bit of feedback, just because it didn't go the way I expected it.

I did just try it. Didn't detect a lot of hop flavour (I used a mix of amarillo + citra + mosaic). I was going for some fruity hop flavours. But wow, it certainly has soured to a nice level. It tastes really good.

I'm going to hit it with a fairly big dry hop now (same varietals), so that should at least get the fruit aromas.

This thread is awesome, thanks so much RPh_Guy for starting it, and being our guide. I'm kind of amazed that I was able to make a sour beer so easily.

I do think discussion on the hop tea method is missing in this thread to some extent. If anyone with more experience on that wants to weigh in, I think it would really help.

I have only made hop tea once, but i can at least add how it went for me. I used 0.5 oz of saaz in a hop bag in 300 ml water. I boiled for 10 mins. Pulled bag out and squeezed liquid out. Then cooler in an ice water bath to room temp and added just prior to kegging. It was more of a hoppy soup; tasted very strong by itself. Once added to 5 gallons, it is just barely noticeable. Very subtle but gives it a nice finishing touch.I do think discussion on the hop tea method is missing in this thread to some extent. If anyone with more experience on that wants to weigh in, I think it would really help.

Beer666

Well-Known Member

- Joined

- Apr 10, 2018

- Messages

- 596

- Reaction score

- 616

So, I tried to make a hop tea... I had 1 oz of hops boiled in 500mL water for 5 minutes. Then cooled for about 30 minutes by setting the pot in a cold water bath.

Basically what I ended up with was hop paste. I squeezed some liquid out through a strainer, but I'd be surprised if I ended up with more than 100mL of liquid into the fermenter.

Did I do something wrong? More water? Less hops?

Thanks!

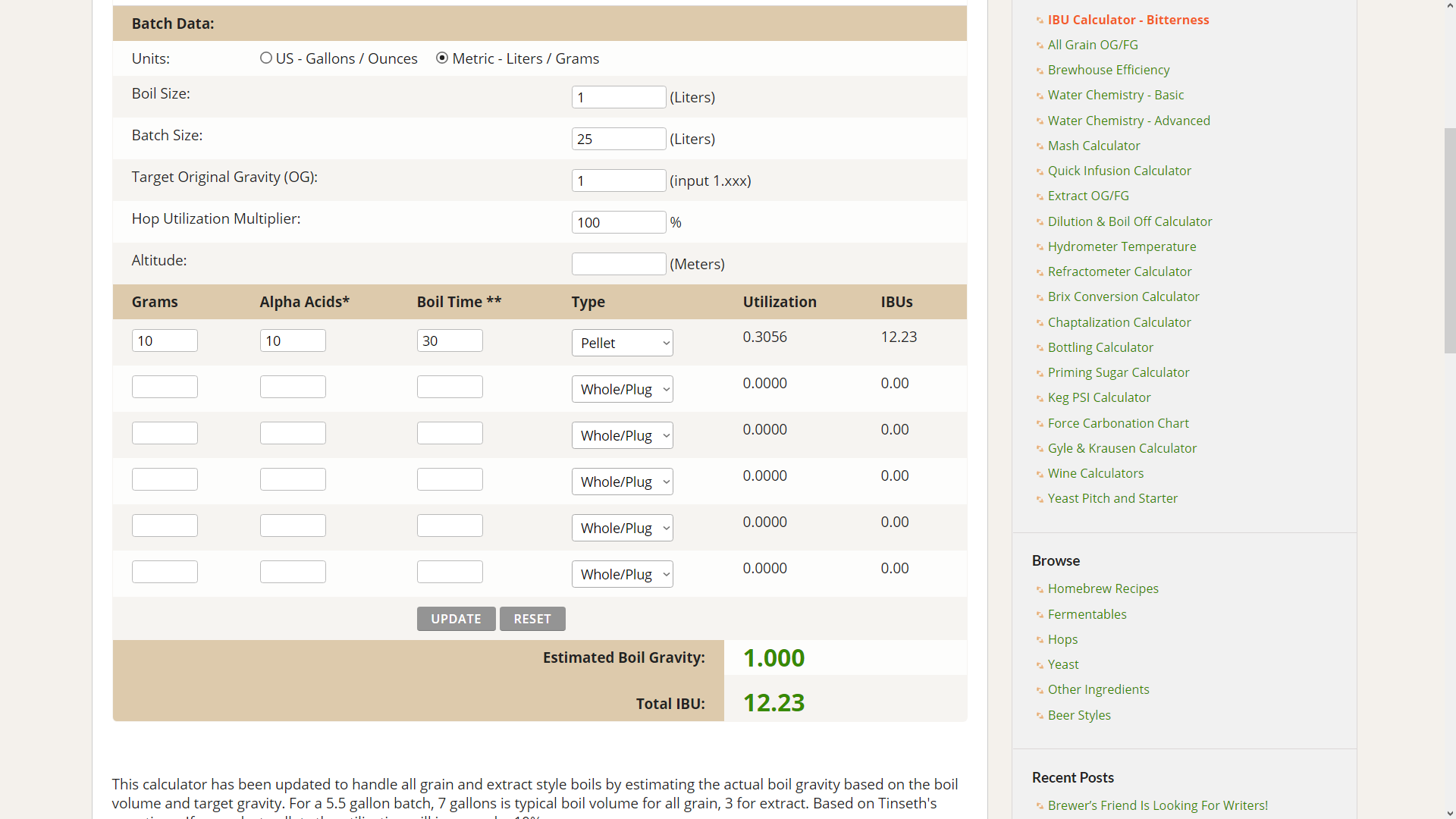

For adding IBU's to my no boil beers i generally boil 1l of water with around 30g of pellets in a nut milk bag for 30m. I end up with around 500ml of tea. For my sour i might just add them to boiled water and let it steep. Use the brewers friend IBU calc for working out IBU. Make sure to set the target gravity to 1( as its water not wort).

For adding IBU's to my no boil beers i generally boil 1l of water with around 30g of pellets in a nut milk bag for 30m. I end up with around 500ml of tea. For my sour i might just add them to boiled water and let it steep. Use the brewers friend IBU calc for working out IBU. Make sure to set the target gravity to 1( as its water not wort).

So this gives you the IBUs of your hop tea. Then to calculate the IBUs of your sour beer after adding hop tea, is it just multiplying dilution factor by hop tea IBU?

e.g. if your hop tea had 200 IBUs and is 300 ml (0.079 gal) and your beer batch is 5 gallons, then: (0.079 / 5) x 200 = 3.2?

Beer666

Well-Known Member

- Joined

- Apr 10, 2018

- Messages

- 596

- Reaction score

- 616

So this gives you the IBUs of your hop tea. Then to calculate the IBUs of your sour beer after adding hop tea, is it just multiplying dilution factor by hop tea IBU?

e.g. if your hop tea had 200 IBUs and is 300 ml (0.079 gal) and your beer batch is 5 gallons, then: (0.079 / 5) x 200 = 3.2?

Your maths sounds right to me. This is how i calculate mine. Link for the calc is here.

1l of water with 10g of 10AA pellets boiled for 30 minutes and added to 25l of wort would add 12.23 IBU's. Target gravity must be one as we are boiling water. I have used this many times and would consider it to be reasonably accurate imho.

Fathand

Well-Known Member

I do not have the ability to keg. Is there any concern bottling these types of quick sours.

I know traditional sours can continue to ferment. Is that the case here?

Thanks.

I know traditional sours can continue to ferment. Is that the case here?

Thanks.

Hey that’s a lot easier. Haha. I overlooked batch size.Your maths sounds right to me. This is how i calculate mine. Link for the calc is here.

1l of water with 10g of 10AA pellets boiled for 30 minutes and added to 25l of wort would add 12.23 IBU's. Target gravity must be one as we are boiling water. I have used this many times and would consider it to be reasonably accurate imho.View attachment 670200

Are you asking if they’ll continue to sour? If so i think the answer is technically yes, although i think you inhibit this if you add hops (hop tea or dry hop).I do not have the ability to keg. Is there any concern bottling these types of quick sours.

I know traditional sours can continue to ferment. Is that the case here?

Thanks.

or do you mean, continue to ferment and produce co2 leading to bottle bombs?

RPh_Guy

Bringing Sour Back

No, there's absolutely no issue with bottling. I bottle all of my beers.I do not have the ability to keg. Is there any concern bottling these types of quick sours.

I know traditional sours can continue to ferment. Is that the case here?

Lactobacillus does not produce significant amounts of carbon dioxide, so there's no risk of over-carbonation.

Cheers

Fathand

Well-Known Member

No, there's absolutely no issue with bottling. I bottle all of my beers.

Lactobacillus does not produce significant amounts of carbon dioxide, so there's no risk of over-carbonation.

Cheers

Yes bottle bombs were my concern. Glad to hear no significant amount of CO2 is produced.

80% pale malt (your choice: pils, 2-row, 6-row, pale ale, MO, Vienna, etc) and 20% unmalted wheat (like wheat flakes or flour).

Beer666

Well-Known Member

- Joined

- Apr 10, 2018

- Messages

- 596

- Reaction score

- 616

So if i want to add say Roeselare yeast/ bacteria after initial fermentation/souring how long will it take? Have to say i am impressed with my latest attempt. I added the lacto after a week then fruit a week later and it has a very nice sourness. its pretty acidic but clean and tasty. Thank You @RPh_Guy i would of still been messing around with kettle souring if not for you. Cheers

RPh_Guy

Bringing Sour Back

What kind of information would be helpful?@RPh_Guy (and anyone else), the two sours I've made used your suggestion for a simple recipe of 50% pilsener, 50% wheat... wondering if you have any variations on this (though still keeping it simple) that you might suggest I could try for my next one?

https://www.homebrewtalk.com/forum/forums/homebrew-sours-wilds-recipes.72/

Literally any of the recipes in the HBT sour recipe database could be adapted for a fast sour process, and even any of the non-sour recipes can be adapted for fast souring. If anything catches your eye I can certainly help adapting it if needed (send me a PM or tag me on a thread).

I could offer a list of grain bills for different malt profiles, a list of flavorful yeast strains, and a list of hops that might be good to try, as well as water profiles and mash schedules ... Would that be helpful to people?

I am building a website. Organizing and editing capability on a forum post doesn't really suffice.

If you just pitch the Roeselare culture, the beer then be ready within a typical "traditional" sour timeframe. It probably needs 3-9 months to reach final gravity and produce flavor. The Brett flavor will be muted to some extent because of the sourness.So if i want to add say Roeselare yeast/ bacteria after initial fermentation/souring how long will it take?

If you're in a hurry, you could add glucoamylase along with Roe, and it'll reach a stable FG rather quickly (couple weeks maybe). Then you could bottle it and the Brett would continue to develop flavor in the bottles, though still muted by the acidity.

Ideally you want the Brett producing flavor before souring (e.g. by pitching a Brett-only starter along with the primary Sacc and then post-sour). With these modern methods, flavorful Brett+Sacc+Lacto mixed sours can be produced in 1-2 weeks ready for bottling.

Is wheat actually important in the grain bill, or do most sour recipes have wheat in them just because it's traditional? There's nothing wrong with that, btw. 100% barley malt will sour, but will it taste right?

Great!

I've been wanting to make a post-sour with Voss, I think the fresh orange flavor will complement the acidity nicely.

...

I wouldn't worry about it. Let it finish naturally, and then add hops when packaging. People are generally happy with where it stops on its own, but you can adjust things next time if you want it more or less sour.

If you're interested in TA levels for comparison, I can test a few of my batches. I don't usually test final pH or TA for beer since it's not really useful for anything. I control mash pH to around 5.4-5.7 and then drop kettle pH to 5.1 toward the end of the boil.

I've poured my first glass of the Berliner Weisse I made using the fast souring method, and thought I'd share my results.

I made a 5.5 gal batch. 4.3 lbs Pilsner and 3 lbs White Wheat malt, mashed at 149F for 90 min. Boiled for 45 min. Chilled to 90F and pitched a pouch of Omega Voss. Let it ferment for 10 hrs and then pitched 16 oz of Mango flavored Goodbelly. Let ferment out for 4 days, added a hop tea (5g Sorachi Ace boiled for 15 min in 1L water: target 6 IBUs), cold crashed for 2 days, and kegged yesterday. Burst carbed @ 40F for 24 hours then set to serving pressure.

Despite the fact that it is not yet carbonated, I think the beer is great. The combination of dry, light, and sour make for a very refreshing beer. It does have a subtle citrus flavor - it reminds me a bit of a lemon ice. I was, however, expecting more sour flavor. I do plan to test final pH and TA so that I can compare that with what I am tasting.

Anyway, thanks again RPh - I will be using this method for my next sour beer! Any ideas for a second sour beer style for someone new to the style like myself?

Last edited:

Gnomebrewer

Well-Known Member

Has anyone tried brewing a Lichtenhainer?

http://www.milkthefunk.com/wiki/Lichtenhainer

I'm thinking I might brew one up this weekend as a co-pitch. 1/3 best pilsen, 1/3 wheat malt, 1/3 best smoked malt to 1.040. But what yeast strain? I'm tossing up between a clean yeast (US05) and hefeweizen (WY3068). Thoughts?

http://www.milkthefunk.com/wiki/Lichtenhainer

I'm thinking I might brew one up this weekend as a co-pitch. 1/3 best pilsen, 1/3 wheat malt, 1/3 best smoked malt to 1.040. But what yeast strain? I'm tossing up between a clean yeast (US05) and hefeweizen (WY3068). Thoughts?

SteveH aka shetc

Well-Known Member

- Joined

- Jul 28, 2013

- Messages

- 3,151

- Reaction score

- 5,675

I brewed a berliner weisse with 50% smoked wheat, and added 6 lbs of mangoes. Used Omega lacto to sour. That keg of beer disappeared in a flash.Has anyone tried brewing a Lichtenhainer?

http://www.milkthefunk.com/wiki/Lichtenhainer

I'm thinking I might brew one up this weekend as a co-pitch. 1/3 best pilsen, 1/3 wheat malt, 1/3 best smoked malt to 1.040. But what yeast strain? I'm tossing up between a clean yeast (US05) and hefeweizen (WY3068). Thoughts?

RPh_Guy

Bringing Sour Back

Wheat isn't necessary for souring or flavor. It's just tasty.Is wheat actually important in the grain bill, or do most sour recipes have wheat in them just because it's traditional? There's nothing wrong with that, btw. 100% barley malt will sour, but will it taste right?

Glad it turned out well!Any ideas for a second sour beer style for someone new to the style like myself?

See my most recent post above.

There's no limit to what you can make by adding flavor from malt, yeast, hops, or adjuncts. Would suggestions for ingredients be helpful? Or just like "here's a Gose recipe"?

Voss gives a really strong fresh orange + orange marmalade flavor when you hold it at 95°F (35°C). It doesn't reach its potential at lower temps from what I've heard.

Cheers!

Not yet, but it's on my list. I would suggest WY1084 (Irish ale yeast) at 65-67°F (19°C). This yeast gives a light fruity background without dominating the profile. Same goes for WY2565 in the same temp range.Has anyone tried brewing a Lichtenhainer?

I'm thinking I might brew one up this weekend as a co-pitch. 1/3 best pilsen, 1/3 wheat malt, 1/3 best smoked malt to 1.040. But what yeast strain? I'm tossing up between a clean yeast (US05) and hefeweizen (WY3068). Thoughts?

Between the two you mentioned I would probably use US-05. I'm just not sure how the weissbier strain would play out with the other flavors.

A pineapple-forward strain like 644 goes well with smoke if you want to get a little crazy.

Gnomebrewer

Well-Known Member

Not yet, but it's on my list. I would suggest WY1084 (Irish ale yeast) at 65-67°F (19°C). This yeast gives a light fruity background without dominating the profile.

A pineapple-forward strain like 644 goes well with smoke if you want to get a little crazy.

Interesting. I hadn't thought of using UK strains - I have some WY1318 on hand at the moment that might fit the bill. Otherwise, I have some 644 in isotonic storage that I could start up. I've used it before in Gose's and really like it. I think I'll give the 1318 a go seeing as it's already up and running from a recent English bitter.

Gnomebrewer

Well-Known Member

I brewed a berliner weisse with 50% smoked wheat, and added 6 lbs of mangoes. Used Omega lacto to sour. That keg of beer disappeared in a flash.

I'm looking to do this one without fruit - most of my fast sours have been fruited. And, like yours, they all seem to disappear super fast - it's amazing how many non-beer drinkers love them, and how many blokey macro-lager only drinkers go back for pint after pint of pink sour raspberry!

When I did my first sour I bottled a couple of litres before racking the rest onto fruits. That "pure" sour was lovely, loads of citrus flavour, so really looking forward to experimenting with just grains and yeasts over time, and the idea of bottling half and then racking the other half onto something appeals to my experimental self.

Gnomebrewer

Well-Known Member

When I did my first sour I bottled a couple of litres before racking the rest onto fruits. That "pure" sour was lovely, loads of citrus flavour, so really looking forward to experimenting with just grains and yeasts over time, and the idea of bottling half and then racking the other half onto something appeals to my experimental self.

I'm thinking I might start taking 10L or so out of each batch of beer I brew in the near future, before hops are added, to run as a fast sour. The cost is minimal, and there's no significant time outlay if I'm brewing the main batch of beer anyway (I can brew up to 80L batches so 10L doesn't really hurt). It'll force me to try using some grains that I probably wouldn't otherwise consider in a fast sour. It could be interesting but could also end with some dumpers!

Yeah but 10L, not much of a loss if you do have to dump the odd batch.I'm thinking I might start taking 10L or so out of each batch of beer I brew in the near future, before hops are added, to run as a fast sour. The cost is minimal, and there's no significant time outlay if I'm brewing the main batch of beer anyway (I can brew up to 80L batches so 10L doesn't really hurt). It'll force me to try using some grains that I probably wouldn't otherwise consider in a fast sour. It could be interesting but could also end with some dumpers!

fendersrule

Well-Known Member

- Joined

- Oct 11, 2018

- Messages

- 703

- Reaction score

- 342

Couple questions as I will use this method soon.

1) Is a 45 minute boil necessary for a White Wheat Malt + 2-Row Grist? I kinda thought 15 minutes should be it--just enough time to sanitize the wort and chiller....

2) Any reason why lacto can't be "pre-pitched" to minimize open-container time? Having to rip apart 10-20 capsules takes time with slippery star-sanned hands. I was thinking why not just do this either a) shortly before the wort goes in the carboy (problem with this is that the lacto will be going right ontop of a thin layer of star san), or b) pitch bugs while the wort is transfering to the carboy--just start pitching it in then. Then finally, add yeast to complete the job.

3) If I read correctly, a 1/2 ounce of dry hops is all it takes to STOP the souring. A) Is this really necessary being that lacto PH curve flattens out pretty heavily at 3.3 or so PH? And B) if it's necessary, about when should I expect to measure the PH so I'm not sitting there doing it every day (which introduces oxygen)? Having a rough timeline on when to check PH is probably a good idea for us that want to try the co-pitch method.

4) Making a fruit sour, means dumping in pasteurized mashed fruit towards the 3-4 days of fermentation mark. According to the FAQ, the beer may already be at 3.3PH at this point....so how does one deal with adding 5lbs of fruit at this point? Blueberries for examble are 3.2-3.3 PH, so I suppose that if the PH was already at 3.3, then I should add blueberries AND dry hop at the same time?

1) Is a 45 minute boil necessary for a White Wheat Malt + 2-Row Grist? I kinda thought 15 minutes should be it--just enough time to sanitize the wort and chiller....

2) Any reason why lacto can't be "pre-pitched" to minimize open-container time? Having to rip apart 10-20 capsules takes time with slippery star-sanned hands. I was thinking why not just do this either a) shortly before the wort goes in the carboy (problem with this is that the lacto will be going right ontop of a thin layer of star san), or b) pitch bugs while the wort is transfering to the carboy--just start pitching it in then. Then finally, add yeast to complete the job.

3) If I read correctly, a 1/2 ounce of dry hops is all it takes to STOP the souring. A) Is this really necessary being that lacto PH curve flattens out pretty heavily at 3.3 or so PH? And B) if it's necessary, about when should I expect to measure the PH so I'm not sitting there doing it every day (which introduces oxygen)? Having a rough timeline on when to check PH is probably a good idea for us that want to try the co-pitch method.

4) Making a fruit sour, means dumping in pasteurized mashed fruit towards the 3-4 days of fermentation mark. According to the FAQ, the beer may already be at 3.3PH at this point....so how does one deal with adding 5lbs of fruit at this point? Blueberries for examble are 3.2-3.3 PH, so I suppose that if the PH was already at 3.3, then I should add blueberries AND dry hop at the same time?

Similar threads

- Replies

- 0

- Views

- 714