I did, the reply was to use the 2nd o-ring as a backup plan. It would probably work, almost certainly, but I wasn't thrilled with how the O-rings squirmed and wrinkled and generally not using the fittings as they were designed.

I have considered getting posts from there, I did see differences in the ones I have. I was going to write and see what his posts looked like, but didn't want to bug him too much. Also I may have found another solution which is to not have the taps poke out between the 2 handles, but finagle them to actually just manage to fit *over* a handle. I'd need to add a picture for that. If it works, I'm done, and don't have to bug him nor buy any more parts. I still need to try it and see.

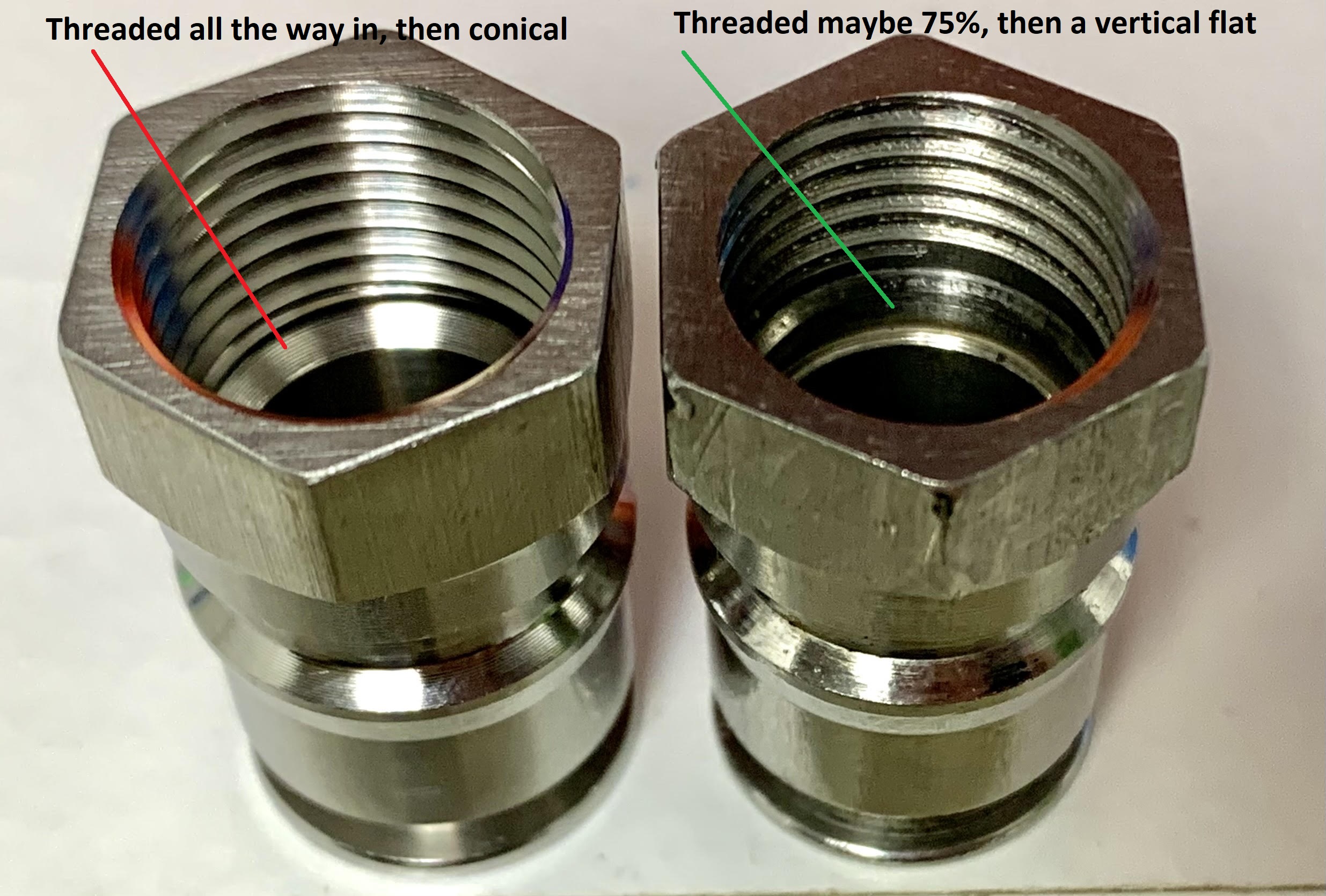

For the posts, see below. The left side post hits the new adapter fitting, and the o-ring at the top doesn't seal to the post. The right side post is shaped perfectly for it that new adapter. And yeah if he's got posts like the right side in stock, I do bet it works. I'd assumed a post was a post, pin locks excluded of course, but - I guess not. Different times, companies, sellers, etc. - different products.

Eh since I have paint up, here's the idea for skipping this altogether. The tap seems that it can be rotated so that it actually just fits over the handle, if lined up just right.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)