You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electrical advice and wiring help for fairly simple RIMS system

- Thread starter JJzeJetplane

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

grandequeso

Well-Known Member

I don't know if you factored this in or not, a 2000 watt element at 120v is 1200/120=16.7 amps and adding your pumps onto that bumps it up at least another amp of two. A 20amp circuit breaker is only meant to take a continuous load of 80% or 16 amps. You probably won't trip the breaker if nothing else is on that circuit. Being as that you are in the design stages it may not be a bad time to address this before you have a problem later. If you do plan to go this route with the 120volt system consider changing the outlet out where you plan on plugging your panel in to a 20amp rated one. Most outlets in a residence are only 15amp rated even though they may be on a 20a circuity. The code allows this as basically no residential loads are that high on a single plug. You'll likely met the outlet if you put that much load on it for sustained amount of time.

grandequeso

grandequeso

JJzeJetplane

Active Member

Well, I decided I was going to go with all copper plumbing, and the closest to a 2000W heater I could find with a low watt density was a 1700W LWD heater. So using that, 1700/120=14.2A. Add in the pump, and I'm right at 16A. I think I should be safe where I'm at, but if I decide to upgrade in the future, this will be something I'll address then. I will make sure that outlet is rated for 20 A. Great point about the outlet though! It's a cased outdoor porch outlet, so I feel like it's one that they wouldn't be able to cheap out on as easily, but you do never know.

grandequeso

Well-Known Member

Sounds good in that case. consider using a 20a rated male cord cap as well. looking foward to how your build goes.

Grandequeso

Grandequeso

JJzeJetplane

Active Member

Yea, I'm excited to get started. I'll try to document a lot of the build in case it works out well and others wish to follow. Thanks for all the feedback Paul, I really appreciate it!

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

JJzeJetplane

Active Member

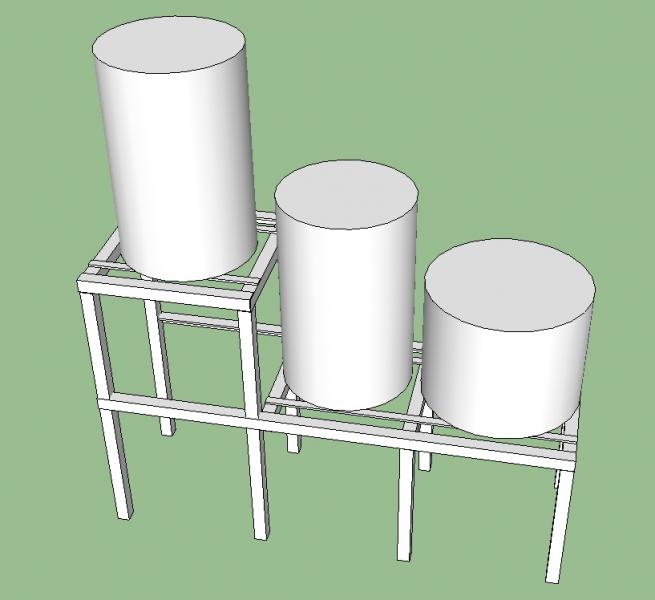

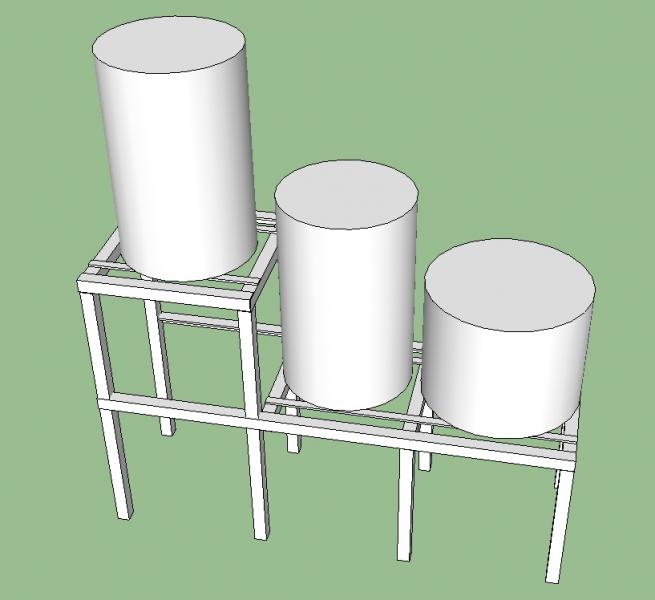

Ok, so I've ordered everything that I'm going to need for this build and I'm waiting on the last 25% of the pieces to come in the mail. I just finished laying out the structure and I'm going to find an aluminum supply store. I'm attaching the model I built with sketchup so I could resolve issues I may have in design. Let me know what you guys think. Heres the parts list for the structure:

(Q) Desc-W"xT"xL"

(2) flat aluminum bars -1"x1/4"x19.5"

(2) flat aluminum bars -1"x1/4"x36"

(9) square tubes - 1.5"x1/4"x18"

(4) square tubes - 1.5"x1/4"x36"

(2) angled aluminum - 1.5"x1/4"x19.5"

(2) angled aluminum - 1.5"x1/4"x55.5"

I did a calculation to figure out the total weight of the structure to see how manageable this is going to be unloaded and my calculation came up with just over 51 lbs (using a density of 0.10 lbs/in3). This seems pretty manageable to me.

(Q) Desc-W"xT"xL"

(2) flat aluminum bars -1"x1/4"x19.5"

(2) flat aluminum bars -1"x1/4"x36"

(9) square tubes - 1.5"x1/4"x18"

(4) square tubes - 1.5"x1/4"x36"

(2) angled aluminum - 1.5"x1/4"x19.5"

(2) angled aluminum - 1.5"x1/4"x55.5"

I did a calculation to figure out the total weight of the structure to see how manageable this is going to be unloaded and my calculation came up with just over 51 lbs (using a density of 0.10 lbs/in3). This seems pretty manageable to me.

JJzeJetplane

Active Member

What do you mean exactly? Are you looking to have the ability to switch on/off each receptacle in the outlet?Quick question, could one use a duplex receptacle and control each outlet separately or do you need to have two different outlets?

The way I plan to wire my system, I will have everything hooked up with a single plug to a single receptacle. If you are planning on having two plugs, you're total amperage on the whole outlet is limited by the both the outlet rating and the breaker serving that outlet.

I really dont know what I mean, I plan on plugging the control panel in the wall on a single socket to power the control panel (4352 auber and 25A SSR) to control a 1500w extra low density coil, and thought of also having a switch to power on my chugger pump. very similar to your setup. so i would have an on off switch for the element and an on off switch for the pump, does that make sense? Also what gauge wire do people use? Would 20 gauge work?

JJzeJetplane

Active Member

Well, if you read from the first wiring diagram on page 2 to the bottom of page 3 in this thread, you'll see the progression of what I originally wanted to what I'm going with now, and suggestions as to why I may want to change them. You'll also notice some of the other factors you'll need to consider.

How does your pump get power; does it have a receptacle plug or a wire with leads on the end?

and thought of also having a switch to power on my chugger pump

How does your pump get power; does it have a receptacle plug or a wire with leads on the end?

JJzeJetplane

Active Member

Also what gauge wire do people use? Would 20 gauge work?

Well, you size wire by how many amps your system uses. Thicker wire= higher amps. You said you're using a 1500W element on a 120V system. Using the formula P=IV (Power=Current*Voltage) and solving for I (P/V=I), we get 1500W/120V=12.5A. If you have separate plugs for your pump, then just put a little safety factor on the wire and you should be good (size for 15A?). Now use a wire sizing chart to see what size wire can handle your load. I found this one using google. Wire Sizing Chart Also note the following asterisk:

* The national electric code (NEC) specifies that the overcurrent protection device not exceed 30A for 10 AGW wire, 20A for 12 AGW wire and 15A for 14 AWG wire.

So there you go, the national electric code says to use no smaller than 14 AWG wire for 15A .

EDIT 1: The 2% voltage drop chart above the max amp chart says that for 15A in 14 gauge wire, you will lose 2% of your voltage at 3 feet. If 3 feet seems shorter than you believe you will be running your wire, than you will need even thicker wire than that.

Josh, thank you so much, this is helpful. I think my setup is going to be just about identical to yours. My final question, and i know its dumb, but can i connect a two duplex receptacle to the two different toggle switches, ie use a single Leviton 15-Amp Duplex Outlet and plug the pump in one and heating element in the other?

grandequeso

Well-Known Member

However you did that voltage drop calculation you did something wrong. I entered 14awg. 35' @ 120V single phase into my voltage drop app I use at work and got 2.9 %. 3%. I believe is the max vd allowed on a single branch circuit (combined loads max vd is 5%)

JJzeJetplane

Active Member

Well there you go. I must not have used that chart right. Well good, that makes me feel quite better about my setup now too.

grandequeso

Well-Known Member

I put together a little combination stack switch / duplex receptacle into a 4" square box with an industrial cover to control my two pumps off of one 120v circuit. My control panel is 30a 240v and I didn't want to screw around with wiring outlets and switches and extra breakers or fuses into it for my pumps. You could easily use the same sort of setup to control any two devices. Its very basic. Line power feeds into the stack swicth. neutral goes directly to the duplex receptacle. break the preforated tab between the two "line side" screws on the receptacle to separate them from each other. Then you wire two little jumpers to the two poles on the stack switch. Took maybe 5 mins and about $5 to put together. I used a cord from an old window a/c someone was throwing away to power it was extra nice as it was free and it had a gfci built into it & it was made of nice heavy gauge wires.

JJzeJetplane

Active Member

Quick update. Everything I've ordered has come in and I've finished wiring the control station. Drilling the aluminum with a battery powered drill is taking forever and then I still need to plumb and support all the piping. I can't wait to brew cause I've got a pumpkin ale and rye IPA ready to run through it.

How did you make out on this build? I am starting to get parts (with the help of Santa) to do the exact same setup. I'm looking to eventually go entirely electric, however tuition costs have me trapped at my parents still and without space for a dedicated setup. So RIMs in a box it is! Currently have SSR, PID, and RTD. Just need switches, lights, and wire.

JJzeJetplane

Active Member

Everything worked out pretty good actually. I'm still looking for a better way to secure my burners to the frame as well as finding a better way to support my hot liqueur tank so that the supports don't overheat while the burner is on. Other than that, everything actually worked well. I suggest a larger box for a control panel than the ammo tin as it was tough to fit everything into, but I did somehow make it work. If you need specific help, let us know!

JJ

JJ

Similar threads

- Replies

- 8

- Views

- 610

- Replies

- 0

- Views

- 753

Latest posts

-

-

-

Canned wort: concentrate vs non-concentrate; hot break material

- Latest: EscapeArtistBrewing

-

-

-