bruce_the_loon

Well-Known Member

After a few years of brewing, I finally got around to start building my fermentation chamber. Now before anyone starts on using fridges etc for a chamber, in South Africa decent second-hand fridges are rare and new ones would have cost me about six times what I've spent on it.

I got hold of a working second-hand water cooler which turned out to have a mini-fridge as well. After much stripping of threads, swearing and tearing apart, I got the compressor unit and the full cooling circuit out intact. Powered it up and it chilled. Part one of the mission completed.

Photo 1 - Compressor and cooling circuit extracted from the water cooler.

Photo 2 - Closeup of compressor and upper cooling circuit. Currently wrapped in foam insulation and paper towel for testing.

Next I rigged up the STC1000 controller to switch the compressor, wrapped the upper cooling circuit, which had been wound around the water bowl, in insulation and placed the temp probe from the controller into a container of water inside the mini-fridge and closed the door. Shifted the temps around a few times and the mini-fridge heat exchanger panel was able to handle temps down to 3°C.

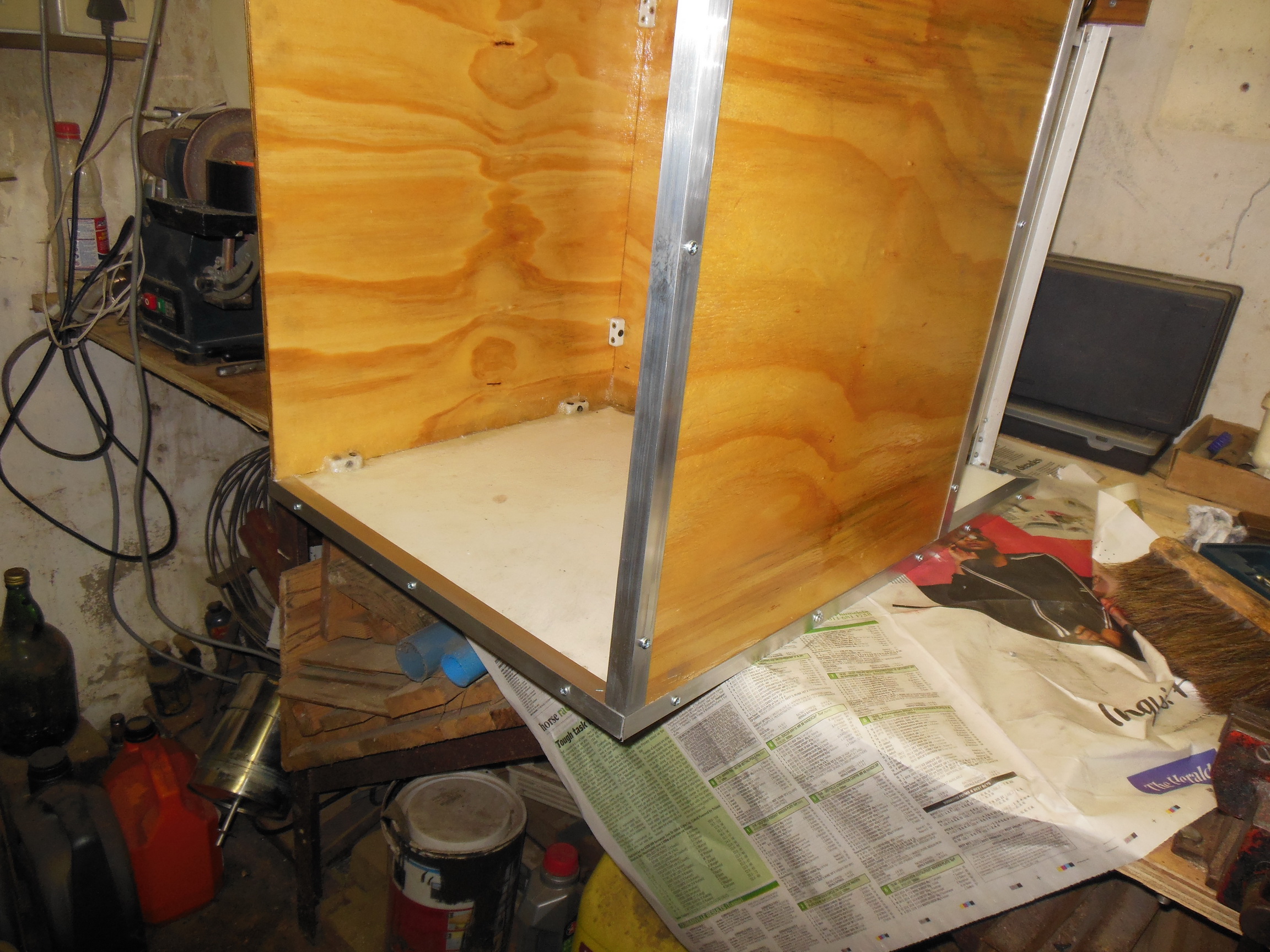

Started to build the chamber itself today. Cut some 10mm ply to size and mounted the sides and rear to the baseboard. Internal dimensions of the chamber are 45cm x 45cm x 90cm (18" x 18" x 36") which will have an effective size of 35cm x 35cm x 80cm (14" x 14" x 32") once the insulation has been fitted.

Photo 3 - Front view of the partially assembled chamber with the port for the mini-fridge chamber cut out.

Insulation is going to be 50mm Isotherm which is a polyester flexible blanket with an R of 0.79. I've used this around my fermenter before. If that doesn't work out, then 35mm polystyrene sheeting is the fallback plan.

Photo 4 - Rear view of the partially assembled chamber with the port for the mini-fridge chamber cut out.

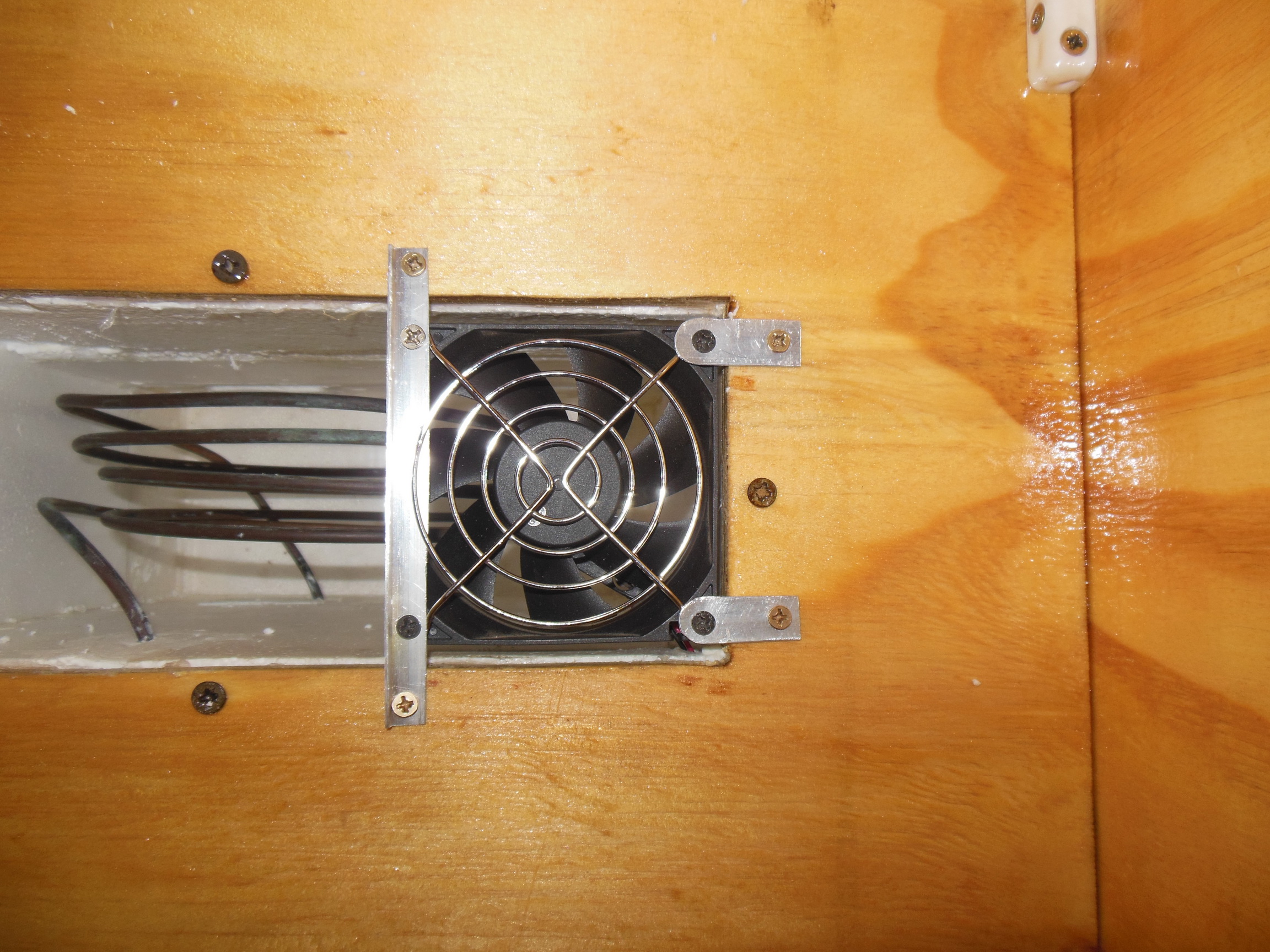

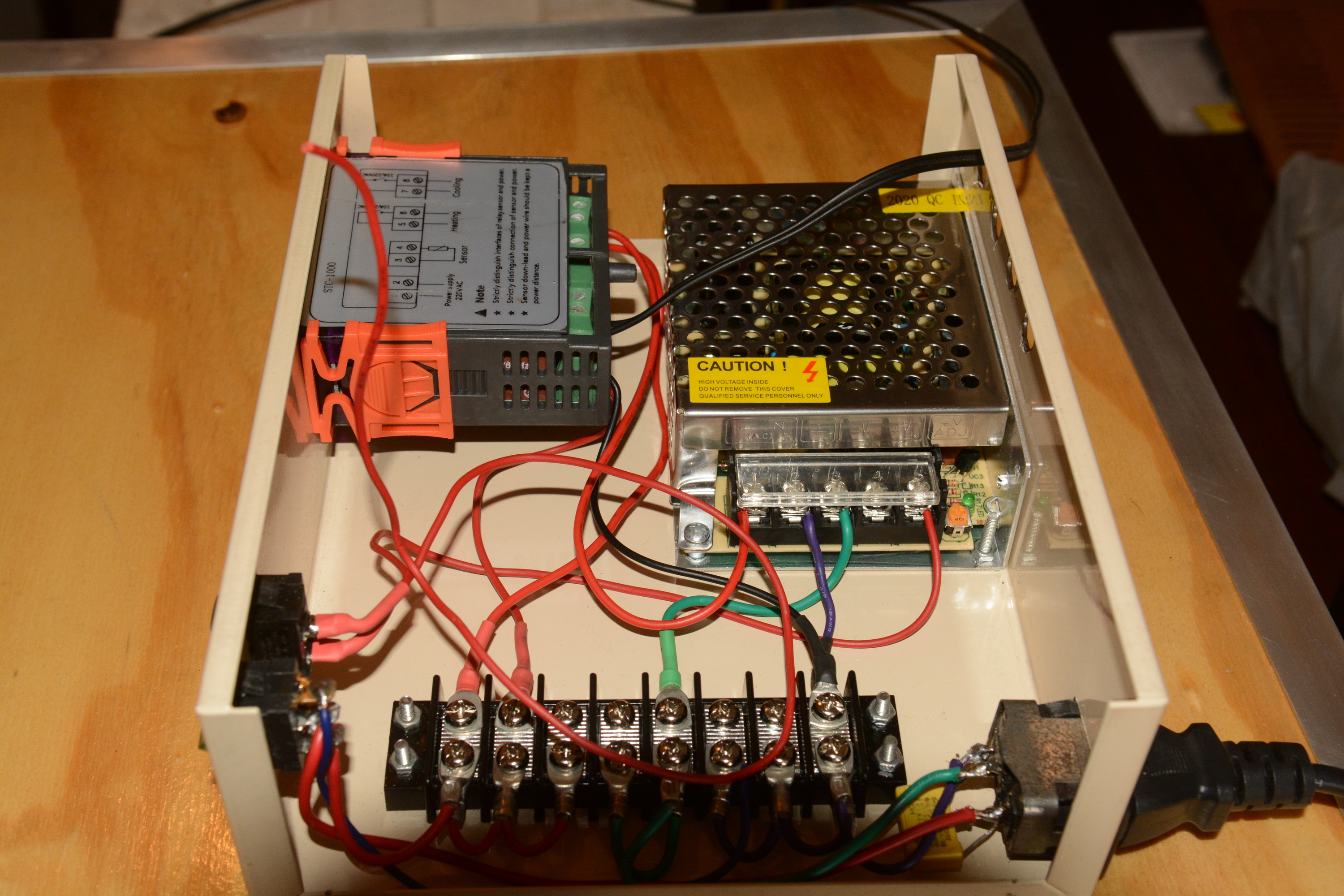

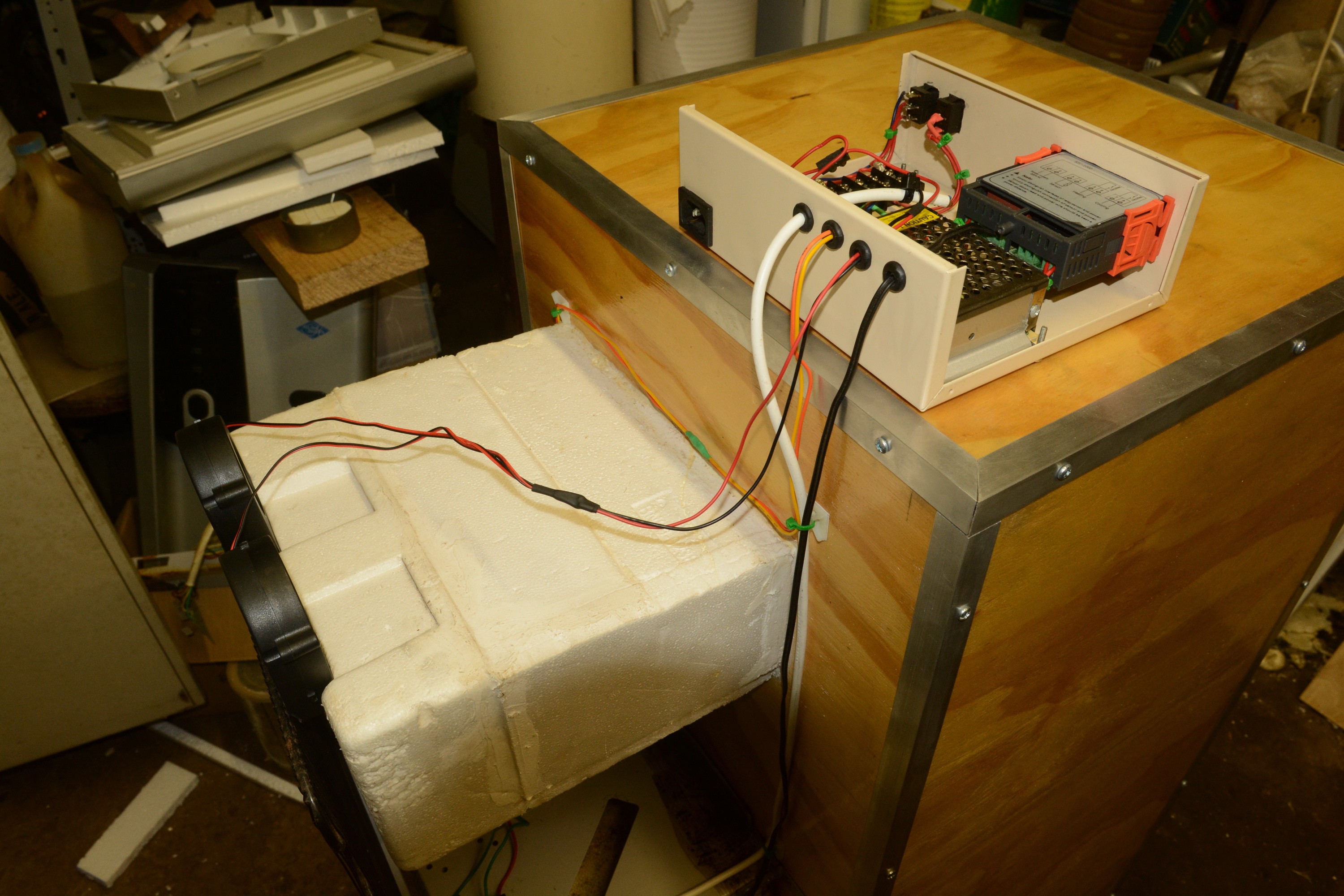

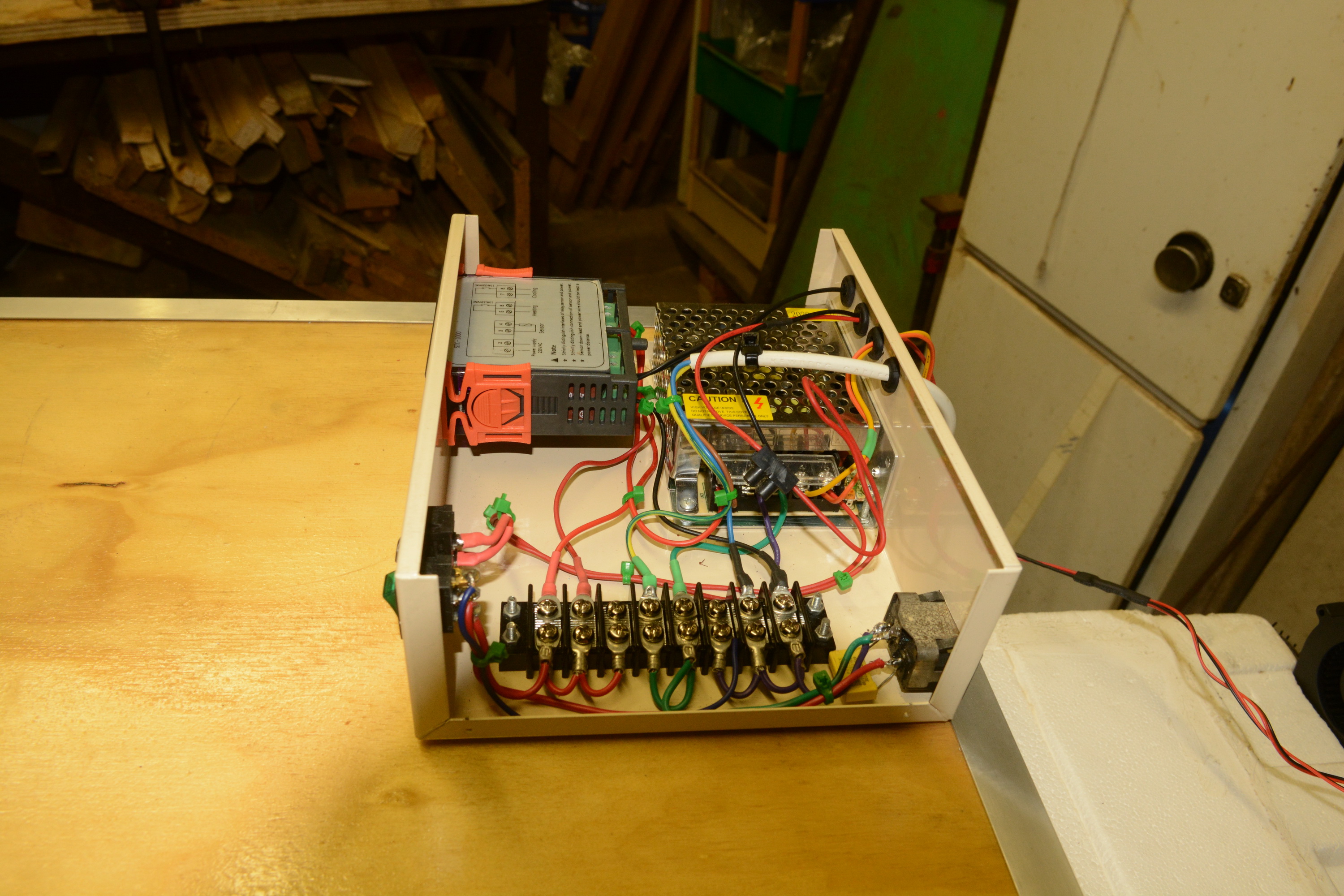

The next step is to fabricate a chamber to enclose the chilling coils that had been wound around the water tank in the cooler. This chamber will be ported into the rear of the fermentation chamber like the mini-fridge chamber and fans will circulate air around both the chilling coils and the chiller plate. The STC1000 will be mounted above the chamber itself with the temperature probe inside the chamber to be secured to the fermenter (or even placed into a thermowell if I ever get around to it.)

Photo 5 - Partially assembled chamber with my Mangrove Jack's 5g stainless steel fermenter.

Next few days will be spent on finishing the chamber construction, mounting the compressor and chiller circuits and figuring out which epoxy sealer to use to waterproof the inside of the chamber before insulating. Then there will be the electrics and the cursing and the testing. More pictures as the various stages are reached.

PS - All the rust on the compressor pipes is from the hot water heater plumbing in the water cooler (which had a hot water function as well) that decided to rust out.

Edit: changed photos to full size

I got hold of a working second-hand water cooler which turned out to have a mini-fridge as well. After much stripping of threads, swearing and tearing apart, I got the compressor unit and the full cooling circuit out intact. Powered it up and it chilled. Part one of the mission completed.

Photo 1 - Compressor and cooling circuit extracted from the water cooler.

Photo 2 - Closeup of compressor and upper cooling circuit. Currently wrapped in foam insulation and paper towel for testing.

Next I rigged up the STC1000 controller to switch the compressor, wrapped the upper cooling circuit, which had been wound around the water bowl, in insulation and placed the temp probe from the controller into a container of water inside the mini-fridge and closed the door. Shifted the temps around a few times and the mini-fridge heat exchanger panel was able to handle temps down to 3°C.

Started to build the chamber itself today. Cut some 10mm ply to size and mounted the sides and rear to the baseboard. Internal dimensions of the chamber are 45cm x 45cm x 90cm (18" x 18" x 36") which will have an effective size of 35cm x 35cm x 80cm (14" x 14" x 32") once the insulation has been fitted.

Photo 3 - Front view of the partially assembled chamber with the port for the mini-fridge chamber cut out.

Insulation is going to be 50mm Isotherm which is a polyester flexible blanket with an R of 0.79. I've used this around my fermenter before. If that doesn't work out, then 35mm polystyrene sheeting is the fallback plan.

Photo 4 - Rear view of the partially assembled chamber with the port for the mini-fridge chamber cut out.

The next step is to fabricate a chamber to enclose the chilling coils that had been wound around the water tank in the cooler. This chamber will be ported into the rear of the fermentation chamber like the mini-fridge chamber and fans will circulate air around both the chilling coils and the chiller plate. The STC1000 will be mounted above the chamber itself with the temperature probe inside the chamber to be secured to the fermenter (or even placed into a thermowell if I ever get around to it.)

Photo 5 - Partially assembled chamber with my Mangrove Jack's 5g stainless steel fermenter.

Next few days will be spent on finishing the chamber construction, mounting the compressor and chiller circuits and figuring out which epoxy sealer to use to waterproof the inside of the chamber before insulating. Then there will be the electrics and the cursing and the testing. More pictures as the various stages are reached.

PS - All the rust on the compressor pipes is from the hot water heater plumbing in the water cooler (which had a hot water function as well) that decided to rust out.

Edit: changed photos to full size

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)