Alan Reginato

Well-Known Member

Kkkk it's spontaneous emulsification. But it sounds a little too technical. Can I blame the Gboard? Kkkk

Yes, dry hopping brings a unique fresh flavour that cannot be accessed through whirlpool or late additions.I was a fan of dry hopping in my beginnings, now I'm not sure any more if dry hopping really brings an added value to me as a homebrewer compared to the risks.

- Dry hopping will introduce enzymes into my beer, splitting up the longer sugar chains and making new sugar available to my yeast, causing a re-fermentation (also called hop creep). This has already resulted in foam exploding beers in my case, and also it will remove some of the body. Specially for the beers I have mashed in at a higher temp to keep more body... this will be ruined by dry hopping and make my beer

dry. I haven't really found a method against this problem yet...

- There is also the issue of hop burn which I have experienced in most of my dry-hopped beers, they taste like old black tea bags during two weeks after bottling or even longer. I've also had it when cold crashing the beer before adding the dry hops and lowering the dry hop quantities will not eliminate this risk completely and it's such an ugly taste.

I've seen on youtube channels that pretty good hoppy results are made with massive quantities of whirlpool hops at 70-80°C / 160-175°F as high as 200g / 0.5 pounds on a 5-gallon / 20l batch. I will try this next time without all the time consuming and risky dry hopping process...

Any experience with putting all your hops into whirlpool, leaving none for dry-hopping?

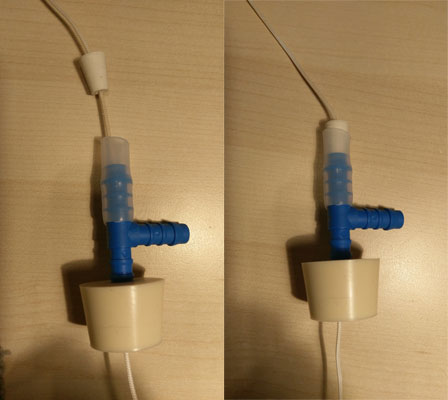

I think my next experiment with low oxidation dry hopping will be to dry hop in sanitized muslim bags tied off with small diameter fishing line suspended from the top of my fermenter. At the appropriate time I will simply crack open the fermenter slightly to lower the bag into the beer with the string and repressurize the fermenter with CO2 (purging it a couple times). This will allow me to repeat this to raise the bag out of the beer when called for by the recipe and use more than 1 dry hop addition if needed.

I've seen some people use magnets to secure their hop bag to the top of the fermenter so they didn't have to open it up at all.

i have tried the magnet trick and it worked ok but it doesn’t allow one to remove the dry hops from the beer after an interval. It also is more complicated to add a second dry hopping addition without more magnets. I am hoping the fishing line method would solve these problems.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)