I've been brewing a little over a year now. I've been doing all grain for the last 7 months. I've had a few "light" beers turn out marginally okay, but for the most part (last 4 attempts) they've got horrible off flavors. I use campden tablets in my water, but I'm still getting a medciney bandaid flavor in anything lighter than an APA. My sanitation is on point, the only thing I can think of is my mash temps or my fermenting temps. I usually ferment in the garage (stays around 55-60 degrees), I have one in there now that the fermometer shows at 58-60. However, I've got an IPA in a carboy in the house (brought in for diacetyl rest) that tastes like cr*p. It was fine when it went into the fermenter. Anything that I've brewed that is fairly dark turns out fantastic (I know the darker malt is probably covering up whatever off flavors it may have). I can't do a recirculating mash (yet, need another pump). I'm about to say the heck with it and go back to extract until I can get it figured out. Any ideas welcome....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dark beers great....lighter ones awful?

- Thread starter seatazzz

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Norselord

Well-Known Member

Add 4oz of acidulated malt.

Sounds like alkaline water to me. Try adding an ounce of acid malt to the mash per gallon of beer, and sparge with RO water (you can buy it in bulk from Walmart for about 30 cents per gallon, bring your own plastic carboy)

That's just to see if it improves things; if it does you can figure out more accurate water adjustments.

Edit: looks like we're all thinking the same thing

That's just to see if it improves things; if it does you can figure out more accurate water adjustments.

Edit: looks like we're all thinking the same thing

Yup. I had the same thing happen to me. I brewed Biermuncher's Centennial Blonde using unadjusted tap water and it was awful. I then tried the tips in here, and my next cream/blonde ales were awesome.

https://www.homebrewtalk.com/showthread.php?t=198460

The short version is try grocery store RO water from the machine, add a tsp of calcium chloride, and sub about 3% of your grist with aciduated malt/sauermalz.

https://www.homebrewtalk.com/showthread.php?t=198460

The short version is try grocery store RO water from the machine, add a tsp of calcium chloride, and sub about 3% of your grist with aciduated malt/sauermalz.

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

if you can smell chlorine in your brewing water, I would recommend you switch to bottled water or invest in a water filter. I have a filter and had the filtered water tested, see https://www.wardlab.com/ for more info. If you are tasting a medicine/band-aid flavor, the campden tablets aren't working or you are sanitizing your cool-side equipment with bleach or similar. If so, stop it. Get some StarSan. Also, monitor your mash temp closely with a calibrated accurate thermometer, if the actual mash temp is lower than the measured temp, you will get a higher alcohol level than you expect. Lastly, your fermentation temperatures are too cool for ales, ok if you're brewing lagers. There are plenty of ways and ideas in the forums on this site to control fermentation temperatures. This could be the biggest improvement towards making better beers and I suggest you consider this. Always remember that this is a fun hobby and it is well worth your time to perfect your recipes and processes, you won't learn as much if you only brew extract recipes.

Thanks for all the responses! Yeah, it is probably the water. I was hoping the campden would take care of it but it must need something else. I'll try the acidulated malt. Was also considering taking 3 empty kegs to a friend's house and snagging some of his water - he brews on a large scale and all of his brews turn out great with city water, with no adjustments. Quick question - what would the acidulated malt do?

Light grains in the mash might get you a mash pH of 5.8ish, which is too high and tastes bad. Aciduated malt lowers the mash pH to a better level.

The 3% of the grist thing all assumes you're using distilled water, though. If your city water has high alkalinity, then you'd need more aciduated malt to make things right. If you don't know the makeup of the city water, though, you're kind of flying blind.

A couple bucks worth of distilled water from the grocery store or Walmart (seriously - like 29 cents a gallon) is really worth it.

ETA : if your buddy has a reverse osmosis system, then awesome! If he's just using plain old city water on the same system as yours, then I'd go for the grocery store distilled water.

The 3% of the grist thing all assumes you're using distilled water, though. If your city water has high alkalinity, then you'd need more aciduated malt to make things right. If you don't know the makeup of the city water, though, you're kind of flying blind.

A couple bucks worth of distilled water from the grocery store or Walmart (seriously - like 29 cents a gallon) is really worth it.

ETA : if your buddy has a reverse osmosis system, then awesome! If he's just using plain old city water on the same system as yours, then I'd go for the grocery store distilled water.

if you can smell chlorine in your brewing water, I would recommend you switch to bottled water or invest in a water filter. I have a filter and had the filtered water tested, see https://www.wardlab.com/ for more info. If you are tasting a medicine/band-aid flavor, the campden tablets aren't working or you are sanitizing your cool-side equipment with bleach or similar. If so, stop it. Get some StarSan. Also, monitor your mash temp closely with a calibrated accurate thermometer, if the actual mash temp is lower than the measured temp, you will get a higher alcohol level than you expect. Lastly, your fermentation temperatures are too cool for ales, ok if you're brewing lagers. There are plenty of ways and ideas in the forums on this site to control fermentation temperatures. This could be the biggest improvement towards making better beers and I suggest you consider this. Always remember that this is a fun hobby and it is well worth your time to perfect your recipes and processes, you won't learn as much if you only brew extract recipes.

I do use Starsan, also iodophor to soak my fermenters (rinsed well after soaking). Haven't used bleach in a looooong time. I'm working on keeping my fermentation temps under control but I've got limited funds.

dyqik

Well-Known Member

I think lactic acid is a bit more controllable than acidulated malt, can acidify your sparge water as well, and it's somewhat cheaper (and will sit on your shelf happily for a year or more). Acidifying the sparge water may be as important as acidifying the mash water if you fly-sparge, when tannin extraction is more likely.

Either start with RO, and trust Bru'n'water or similar to predict your mash pH and required lactic acid addition (as well as lactic addition for your sparge water), or get a Ward Labs test, and then trust Bru'n'water to predict your mash pH, as a first pass. Eventually you might want a pH meter, but you can get away with just calculating as long as you know your water.

By the way, you may find that the standard rate of Campden tablet use (1/4 tablet per five gallons) is not sufficient. If you can still smell chlorine in the water after the Campden has completely dissolved, then there's no problem with adding more until the smell of chlorine goes away.

Either start with RO, and trust Bru'n'water or similar to predict your mash pH and required lactic acid addition (as well as lactic addition for your sparge water), or get a Ward Labs test, and then trust Bru'n'water to predict your mash pH, as a first pass. Eventually you might want a pH meter, but you can get away with just calculating as long as you know your water.

By the way, you may find that the standard rate of Campden tablet use (1/4 tablet per five gallons) is not sufficient. If you can still smell chlorine in the water after the Campden has completely dissolved, then there's no problem with adding more until the smell of chlorine goes away.

......I'm working on keeping my fermentation temps under control but I've got limited funds.

I use a large tub (will hold 2 of the 7 gallon Fermonsters) with a water bath, an aquarium heater and this

https://www.amazon.com/gp/product/B00V4TJR00/?tag=skimlinks_replacement-20

I use the same setup, minus the water, with a ceramic heat bulb to keep my yeast starter at the right temps. I brew exclusively in the garage and keep my supplies and this setup in a small storage cubby, as I call it, located in the garage.

Last edited by a moderator:

I use a large tub (will hold 2 of the 7 gallon Fermonsters) with a water bath, an aquarium heater and this

https://www.amazon.com/gp/product/B00V4TJR00/?tag=skimlinks_replacement-20

I use the same setup, minus the water, with a ceramic heat bulb to keep my yeast starter at the right temps. I brew exclusively in the garage and keep my supplies and this setup in a small storage cubby, as I call it, located in the garage.

This is basically what I do. I have a temp probe which is actually in the beer. I just finished fermenting an IPA which i controlled to 63-65 degrees for two weeks. Added a couple ice bottles when it was at peak fermentation to make sure it didn't warm up beyond that.

Last edited by a moderator:

I think lactic acid is a bit more controllable than acidulated malt, can acidify your sparge water as well, and it's somewhat cheaper (and will sit on your shelf happily for a year or more). Acidifying the sparge water may be as important as acidifying the mash water if you fly-sparge, when tannin extraction is more likely.

Either start with RO, and trust Bru'n'water or similar to predict your mash pH and required lactic acid addition (as well as lactic addition for your sparge water), or get a Ward Labs test, and then trust Bru'n'water to predict your mash pH, as a first pass. Eventually you might want a pH meter, but you can get away with just calculating as long as you know your water.

By the way, you may find that the standard rate of Campden tablet use (1/4 tablet per five gallons) is not sufficient. If you can still smell chlorine in the water after the Campden has completely dissolved, then there's no problem with adding more until the smell of chlorine goes away.

Nice, thanks. I'm already looking into getting RO water, and will spend this boring afternoon at work reading the pH section in How To Brew again. Can I just use those pH testing strips to check my water? Our local water supplier has a 2015 water report but nothing newer.

If you really want to get a handle on water chemistry, then get Palmer's "Water" book. I don't have a science background so I had to read a couple of the chapters more than once, but as soon as it clicked, it completely revolutionized my brewing.

brewprint

Well-Known Member

- Joined

- May 7, 2014

- Messages

- 1,616

- Reaction score

- 169

If you really want to get a handle on water chemistry, then get Palmer's "Water" book. I don't have a science background so I had to read a couple of the chapters more than once, but as soon as it clicked, it completely revolutionized my brewing.

I believe that Beersmith 2 uses Palmer's method for adjusting mash pH. I've found it to be extremely far off for the most part. I'm not saying Palmer doesn't have it right but it sounds like it might not be the best way to go. He has a lot of other interesting information on water.

dyqik

Well-Known Member

Nice, thanks. I'm already looking into getting RO water, and will spend this boring afternoon at work reading the pH section in How To Brew again. Can I just use those pH testing strips to check my water? Our local water supplier has a 2015 water report but nothing newer.

The pH of your water isn't that important, it's the alkalinity (ability to buffer acids in the malt) that matters, and that drives the mash pH. Two tap waters could have a similar pH, but give completely different mash pHs if one is high mineral content and high alkalinity, and the other low mineral content and low alkalinity.

pH strips aren't generally very accurate, and not much use at measuring mash pH, although people report fairly good results with specific brands. A _good_ pH meter is a safer bet, but again, many cheap ones aren't up to the job. The Brew Science subforum has some threads on that.

Your 2015 report should give a reasonable idea of the water alkalinity and ion content, as it probably doesn't change that much from year to year if you are in a large water system (I'm guessing that Seattle has a fairly stable water supply - if you are in Seattle proper then the water is low alkalinity from both Cedar and Tolt is pretty low alkalinity based on the latest quarter result from here). If it's low ppm (mg/L = 1000 µg/L) on all the brewing related ions, then treat it much the same as RO water. Otherwise, it may be worth getting a Ward Labs report.

There's a sticky thread in the Brew Science subforum on brewing with low alkalinity water. If that applies to you, then it's all fairly simple from there.

Wow, didn't see that report when I was looking. Way more information. What would be considered "low" alkalinity? The report I have shows 23.9 mg/L, and there is no maximum level given.

dyqik

Well-Known Member

I think that counts as low for brewing purposes, and probably explains your problem with light beers.

My tap water has moderate mineral content and an alkalinity of 86mg/l. It needs about 3-5 ml of lactic acid for amber through pale beers. You'll need less than that, but without it, your mash pH for pale beers and your sparge water pH will be too high.

Keep an eye on the chlorine/chloramine as well though.

My tap water has moderate mineral content and an alkalinity of 86mg/l. It needs about 3-5 ml of lactic acid for amber through pale beers. You'll need less than that, but without it, your mash pH for pale beers and your sparge water pH will be too high.

Keep an eye on the chlorine/chloramine as well though.

Fantastic, thanks. Silly question I know, but is the lactic acid added to the water pre-mash or during the mash/sparge? I like to heat all of my strike/sparge water at once and only use what I need; any left over after the sparge is cleaning water.

brewprint

Well-Known Member

- Joined

- May 7, 2014

- Messages

- 1,616

- Reaction score

- 169

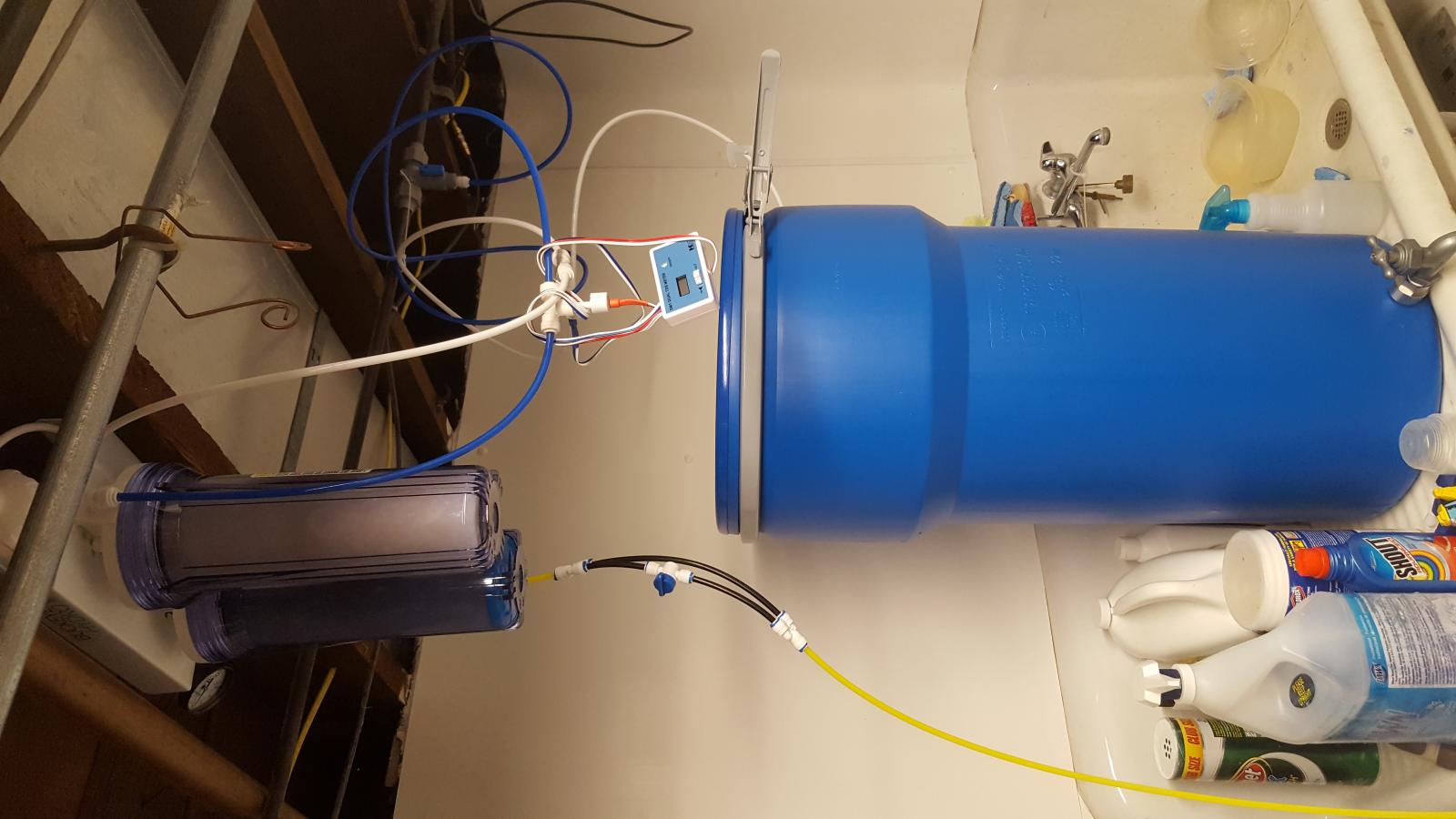

Here's a picture of the tank that I use. I keep it inside of my basement and just fill brewing buckets full and take them outside on brew day or the night before.

It sits there full of water.

I'll see about posting a pic of the system since it's been hooked up after I took this pic of where I was going to put the bucket.

It sits there full of water.

I'll see about posting a pic of the system since it's been hooked up after I took this pic of where I was going to put the bucket.

brewprint

Well-Known Member

- Joined

- May 7, 2014

- Messages

- 1,616

- Reaction score

- 169

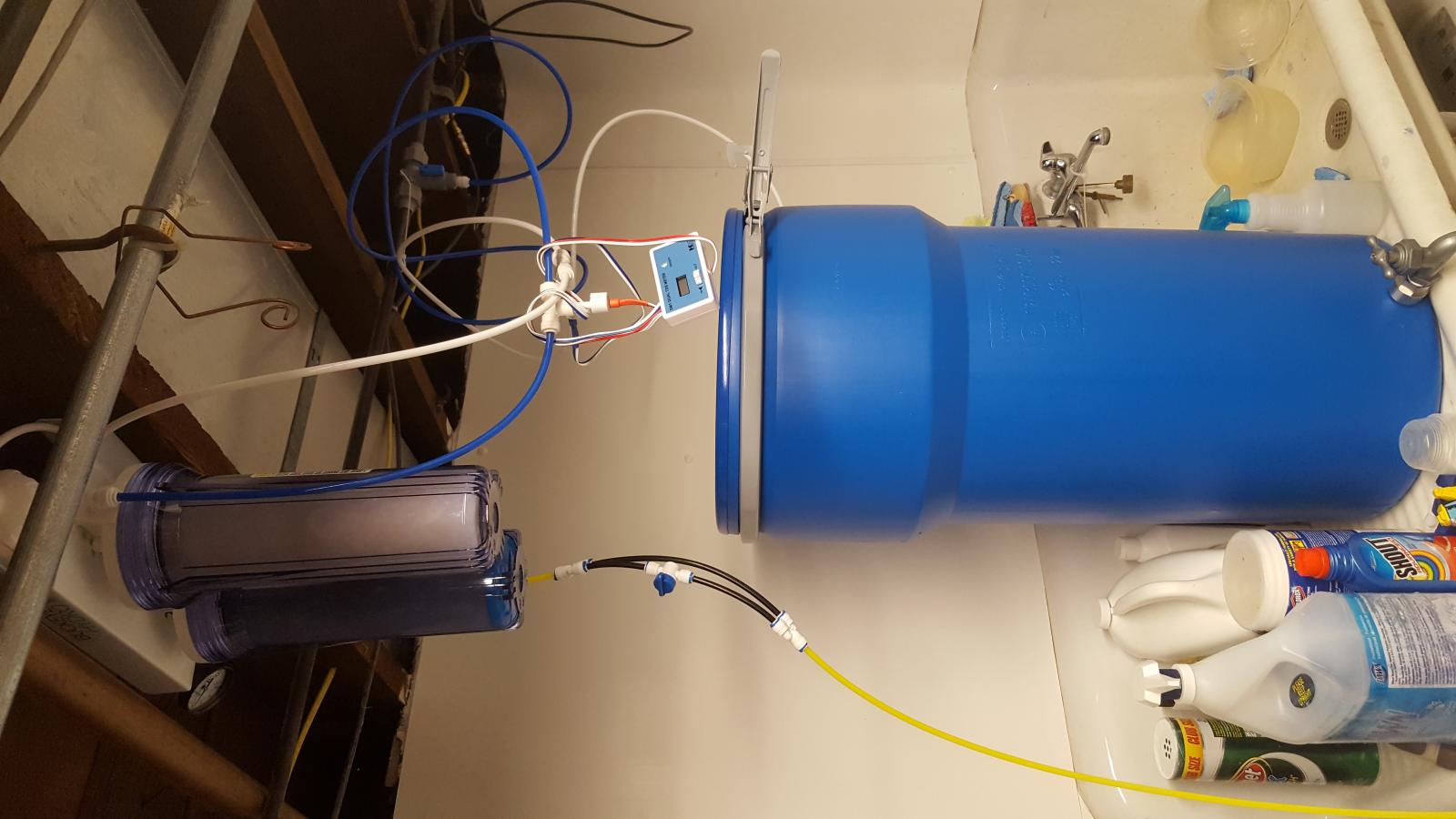

Here's my simple set up.

I usually just keep the tank full. This way I can have water on a spur of the moment brew day.

There is a 3/32 hole drilled in the side to relieve air pressure. When I fill buckets I remove the lid seal.

Sorry for the sideways pic.

I usually just keep the tank full. This way I can have water on a spur of the moment brew day.

There is a 3/32 hole drilled in the side to relieve air pressure. When I fill buckets I remove the lid seal.

Sorry for the sideways pic.

Think I'm having the same issue with my lighter beers... No matter what malt / hop combos the lighter beers all have this similar flavour.... It's not an "off" issue but maybe something that can be attributed to some compound in my tap water....

Sorry if I'm hijacking the thread but do you guys see anything noticeably wrong with my water?

http://www.sydneywater.com.au/web/g...ments/document/zgrf/mdq0/~edisp/dd_044731.pdf

Sorry if I'm hijacking the thread but do you guys see anything noticeably wrong with my water?

http://www.sydneywater.com.au/web/g...ments/document/zgrf/mdq0/~edisp/dd_044731.pdf

Puddlethumper

Well-Known Member

I do use Starsan, also iodophor to soak my fermenters (rinsed well after soaking). Haven't used bleach in a looooong time. I'm working on keeping my fermentation temps under control but I've got limited funds.

Starsan and iodophor aren't responsible for your problems here. As others have posted either check your mash PH with a meter or get your water tested so you can ball-park it into the right pH. Remember, there is a reason pilsner beer comes from Pilsen CZ ...its their water. Same reason great porters come from London and other parts of the UK - again its the water. Pilsen CZ can't make a decent porter without major modifications of their water. Neither can a brewer in London make a good pilsner without spending some time adjusting his water profile.

Find out what your water is best suited for and either brew those kinds of beers or be prepared to adjust your water so you can brew the beers you want.

dyqik

Well-Known Member

Fantastic, thanks. Silly question I know, but is the lactic acid added to the water pre-mash or during the mash/sparge? I like to heat all of my strike/sparge water at once and only use what I need; any left over after the sparge is cleaning water.

Lactic acid for the mash goes in the mash water as or just before you mash in. Lactic acid for the sparge water goes in the sparge water before you start using it.

Similar threads

- Replies

- 76

- Views

- 4K

- Replies

- 10

- Views

- 2K

Latest posts

-

-

-

Need help diagnosing lower than expected efficiency

- Latest: micraftbeer

-