- Joined

- Jan 4, 2015

- Messages

- 112

- Reaction score

- 73

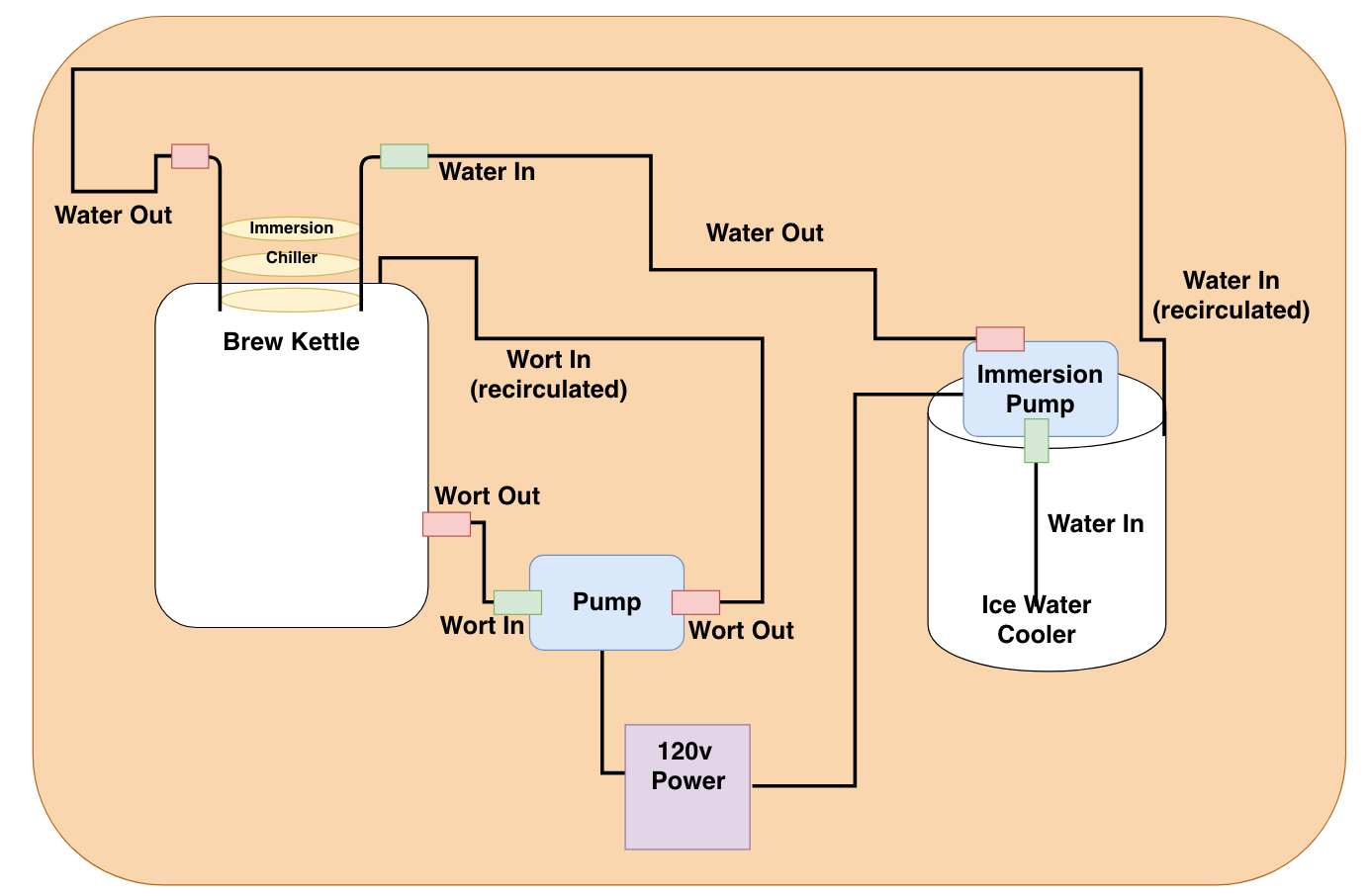

Hello everyone! I am interested in automating my wort cooling process. Currently, I am using the setup shown in the first image below (2 immersion wort chillers, one in the BK and one in an insulated Ice Water Cooler). It works for the most part and cools my water in about 10 minutes with vigours stirring of the wort and agitation to both immersion chillers. This manual process of agitation and stirring is cumbersome. Without stirring and agitation, it would probably take 20-30 or longer. I am hoping to introduce something a bit more automated and less wasteful on water.

I am wondering if this setup is possible (see image below)? I know folks use something similar to this in HERMS setups. This would allow me to just let the pump do the work and all I would need to do is ensure the Ice Water Cool has enough ice to cool down the dimension chiller. Please let me know ya'lls thoughts and whether this setup is worth investing in. Also, any complications or advice I should know about this. Thanks in advance!

Cheers!

I am wondering if this setup is possible (see image below)? I know folks use something similar to this in HERMS setups. This would allow me to just let the pump do the work and all I would need to do is ensure the Ice Water Cool has enough ice to cool down the dimension chiller. Please let me know ya'lls thoughts and whether this setup is worth investing in. Also, any complications or advice I should know about this. Thanks in advance!

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)