(Not shown) Using the wires from the inside of the electric cord that was purchased, cut half way (25') through the cord. Set the male plug end aside, you will use all 25' of it. With the female end, remove the female end of the plug, and cut the remaining length into 5' lengths. Strip the outer casing, so you can get to the 3 wires inside, and set them aside. With the soldering iron, tin one end of the 5 black lengths of wire, and one white wire. Label the black wires with the colored tape at both ends. Also, use a punch to punch out the hole next to the main hole for the probe (There is also one on the side that you may use if you wish)

Pic 11: After tinning all the wires, insert the tinned end into the appropriate relay point on the controller. Wrap the loose ends together in electric tape to slide them through the braided tubing easier.

(Not shown) Strip about 1' on the male side of the length of electric cord, so you can get to the wires inside. Solder the black wire from the power cord to one end of the fuse holder. Solder another length of black wire to the other end. I had to install the fuse holder, then solder the wires to it.

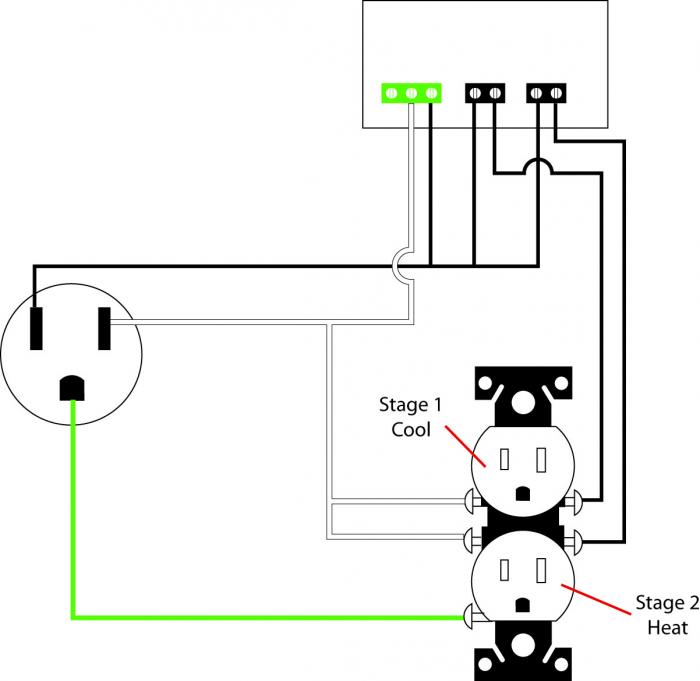

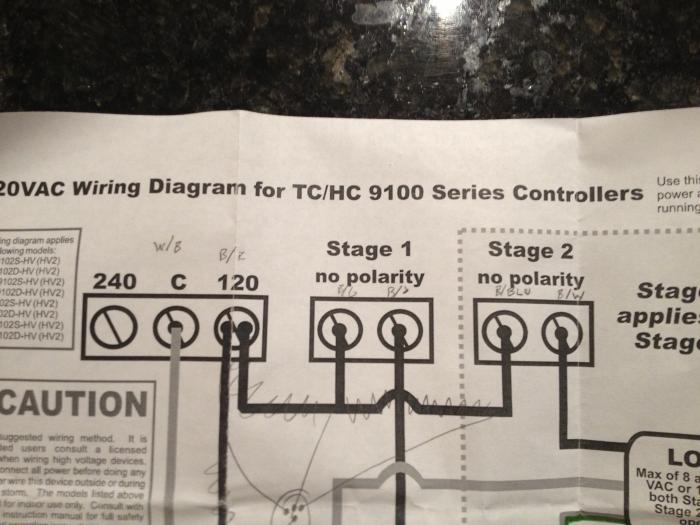

Inside one wire nut, wire together the black wire from the power cord (fuse holder), the black wire with red tape, the black wire with green tape, and the black wire with blue tape. With the other two black wires from the controller, wire them to the appropriate outlets. My black and yellow goes to the outlet on the left, and the black and white goes to the outlet on the right.

Using the other 5' lengths of wire that came with the black 5' lengths, cut 2 - 1' lengths of white and black wire.

In another nut, wire together the white wire wire from the controller, the white wire from the power cord, and 2 - 1' lengths. Connect one loose end to each of the outlets.

In another wire nut, wire together the green from the power cord, and 2 - 1' lengths. Connect one loose end to each of the outlets.

Pic 12: All wired up inside the project box. Use the multimeter to test all your connections before plugging in.

Pic 13: It's working!

Pic 14: I used 3M Command strips to hang the controller and project box on the outside of the freezer (fermentation chamber)

Pic 15: Been holding a steady temp for 3 weeks now!

I hope this helped and wasn't more confusing!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)