Have you tried a pressure washer? Lye?

If none of those work, bail on that keg and get a new one. Once you have a good clean keg, clean it immediately after each use and it will be very easy to clean.

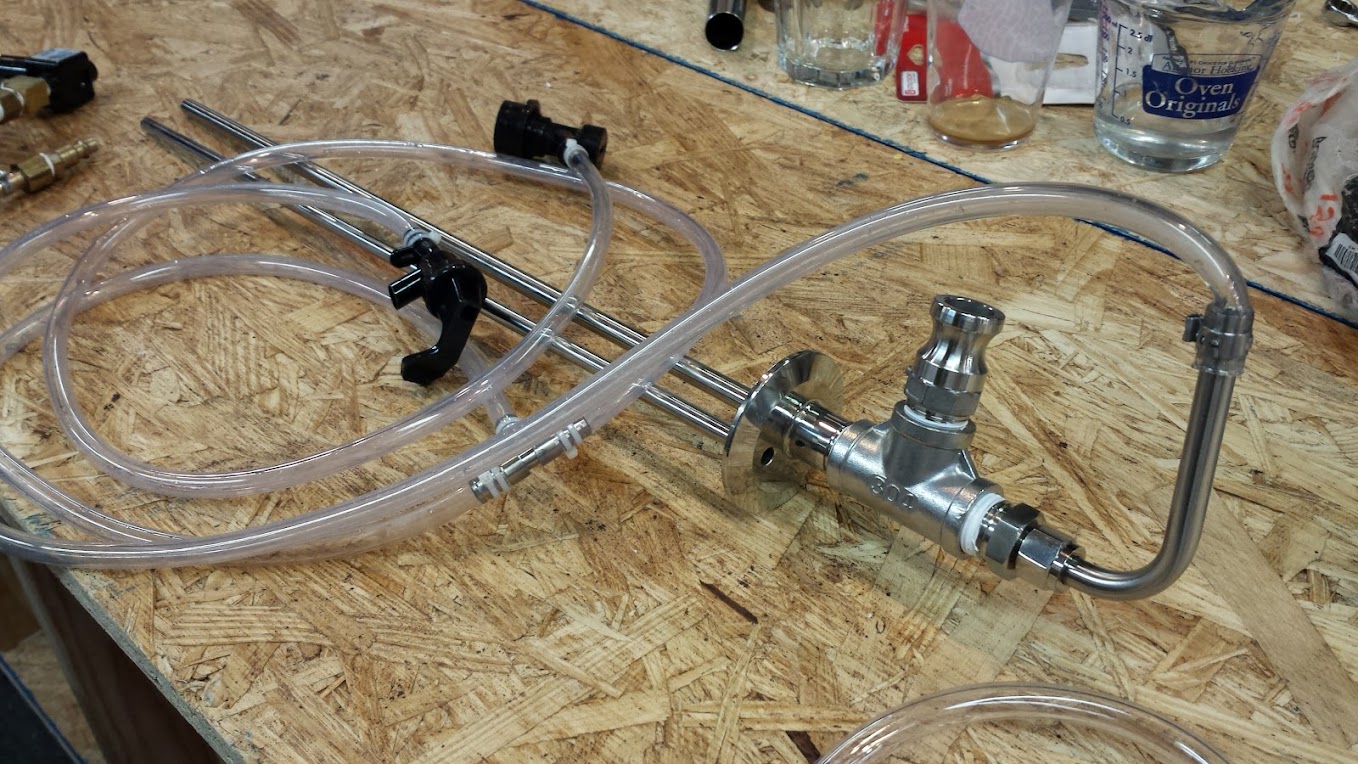

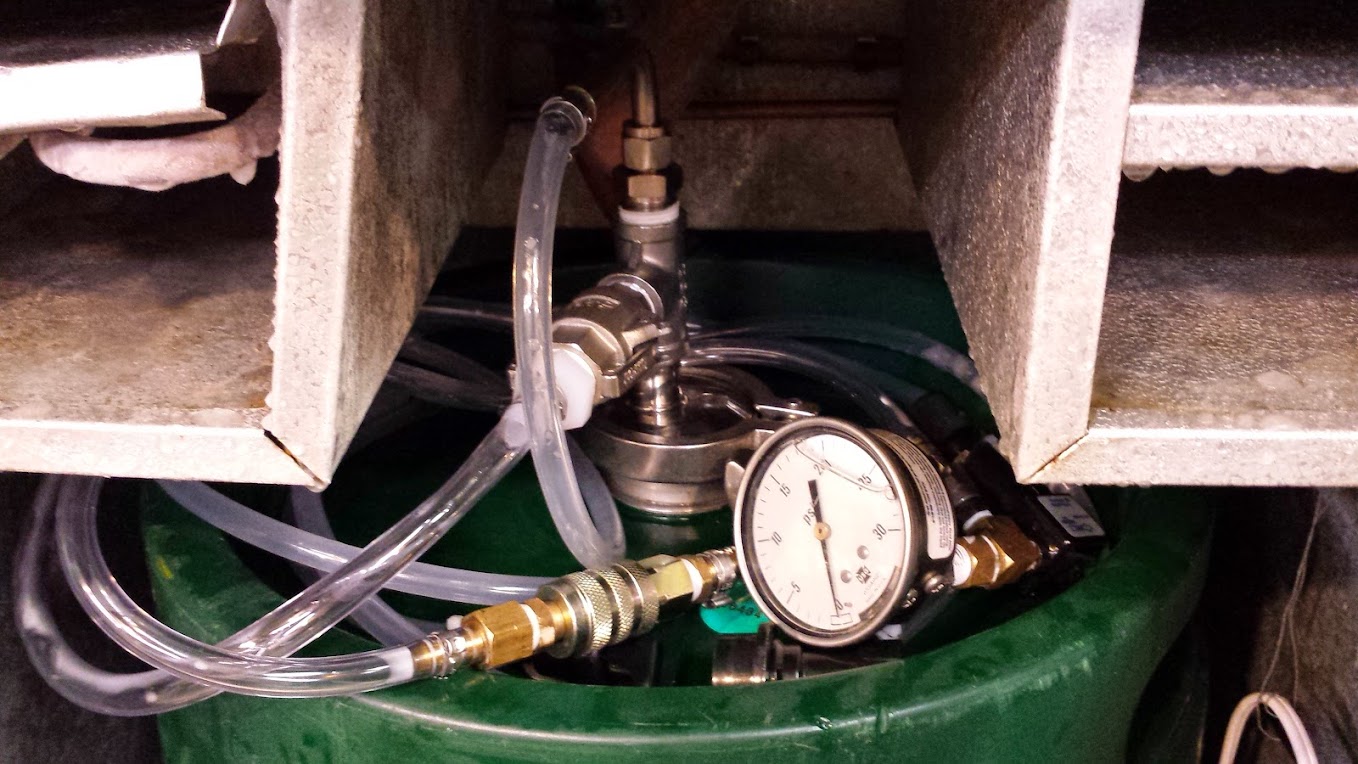

I use a 2' TC cap drilled and tapped to accept a compression coupler for the racking cane and a NPT to accept a T which has a Gas-in post and an adjustable PRV.

Works great, and I would not change a thing.

Need some help please -

I took your advice and bailed on the problem keg and found a different one.

Now the fun really starts-

I have 3 sanke fermenter kegs in rotation. I have been lately putting about 8 gallons of boiling water with about 8 oz of pbw in the water, putting this in the keg, sealed up with a TC and butt cap and let it sit, roll around, flip it every morning and night until I need to get it ready for the next brew... maybe a week or 2 the solution will be in the keg.

I then rinse out the keg with water and then put in a 1/2 gallon of starsan and roll that around in the keg, then fill with wort.....

Before I fill them I use a lighted inspection mirror and saw no gunk/krausen/etc.

I have spray bottles of starsan and always spray spray spray whatever is needed.

I have also switched over to all TC fermenter kits trying to avoid cleaning/infection issues. Re did all the hoses and connections.

The first keg I have tried this with has the same, all be it slight, sour infection, the beer wont clear, has a the smell of the same infection I keep passing around. This is in a Munich Helles, so the infection is not hard to spot.

I used brand new yeast, re did all the liquid hose connection and cleaned them well. Re did the gas hoses also.

Now so far... I have beer in the other 2 kegs that will be racked into cornys this week but so far the samples do not have the infection that I can taste... but of course the infection is easier to tasted as the beer clears up.

I saved the yeast off this batch and tasted the beer that settle out of it, it too taste like the corny keg beer, so there fore the infection started in the keg, or earlier in the process... but I have never had this issue when using carboys... - and actually have some Kolsch in a carboy I will taste soon... to be sure this problem is only related to sanke keg(s)

So do I swap out this keg also? If the keg is clean can it be holding an infection?

What else can I do to clean the kegs better?

How can anything survive boiling PBW that is actually vacuum sealed?

Can an infection be spread by the PRV?

Any help would be appreciated

thanks Kevin

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)