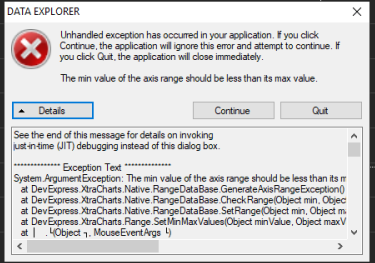

I think this would work:

As

@BrunDog said, you cannot use on/off with a hysteresis device. They have no state property, only the enabled property for On/Off.

[start]

Beer_Temp" Enabled = true

"Set_Temp" Enabled = true // enables temperature setting global element

new value High_Temp // creates a new variable named High_Temp

new value Low_Temp // creates a new variable named Low_Temp

[loop]

High_Temp = "Set_Temp" Value + 1 // sets high temp trigger as setpoint + 1 deg

Low_Temp = "Set_Temp" Value - 1 // sets low temp trigger as setpoint - 1 deg

if "Beer_Temp" Value > High_Temp

"Fridge" Enabled = true

"Heat" Enabled = false

else

"Fridge" Enabled = false

endif

if "Beer_Temp" Value < Low_Temp

"Fridge" Enabled = false

"Heat" Enabled = true

else

"Heat" Enabled = false

endif

goto "loop"

I had this in it as well but I do not think you need it:

if "Beer_Temp" Value < High_Temp

if "Beer_Temp" Value > Low_Temp

"Heat" Enabled = false

"Fridge" Enabled = false

endif

endif

Generally, your compressor device (Fridge) should not cycle less than 12 minutes apart as a general rule of thumb for short cycling. It is hard to find a good definition of "short cycle" in terms of minutes as to what a short cycle is, but 5 times in an hour (60/5=12) is the lowest number I have seen. Some suggest 4 times for a 15 minutes period between cycles. You should time your cycles and add some delay if needed. The time for a short cycle may be in the manual for the fridge.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)