JoepH

Active Member

Great contribution to this thread. Now I understand why the bluetooth thermometer is improving my brewing so much. The build in probe in this way is only a guardrail.

I use a brew bag on my 35L Gen4. I have found this works very well to minimize problems associated with hops and grain debris. In addition I've seen many questions on holding mash temps. I overcame this with an 18" analogue thermometer. I use the top grain screen in the mash tun and put the probe through the center opening of the screen. My thermometer has both F & C. I have also found that I get more consistency out of the Gen4 by running everything in metrics. And yes I am in the US and do not have and issue with metrics. By doing this method I make minior adjustments to my hearting elements. Once I achieve the proper mash temp I reduce my wattage to 1125 and my hysteresis to 0.1C . Using this method I have been able to keep my mash within the +/- 0.1C. The whole process tkaes me less than one minute to accomplish. I hope this helps.Honestly I think I'm going to just continue with the brew bag. At the end of the day it really only adds maybe 2-3 minutes of cleaning time onto a brew day and just flat out works. Just glad the option is available!

I agree that 3 is far too high. I set mine at 1.5, but I also use the PID (with settings of P=0.48, I=0.020 and D=0.00). and . I'm not sure if you use the PID whether or not the heating hysteresis also kicks in - the documentation is not clear on that, but in practice the heating hysteresis setting seems to work in combination.For you guys experiencing overshoots, have you dropped the hysteresis down to 0.5 or less?

Thanks for your advice SkyPie, we're thinking along similar lines.For you guys experiencing overshoots, have you dropped the hysteresis down to 0.5 or less? This is the dead zone in the temp control algorithm, where the algorithm takes this value +/- on the setpoint and thinks "temp good, do nothing". The default value is 3, which is crazy, even in an on-off control scheme. With it set there, you will see the temp oscillate +/-3 or more around the setpoint in the graph. makes precise mash control impossible.

Normally I would put this at 0 with a PID, but I haven't pulled a data sheet on the heating relay they used, so I have no idea of the lifetime cycles it is rated for. Putting between 0.2 and 0.5 cuts down on relay cycles a bunch, without really killing the temp accuracy.

My first couple brews my upper third grain temp was pretty close to the setpoint, and I hit my numbers spot on. Then I realized the temp showed low when it was just sitting at room temp, as well as mash in, so I did a calibration. It fixed the room temp and mash in temps, but my actual grain temp during the mash was suddenly very low. Ended up making a thin-bodied 7.5% red ale before I realized I was mashing at 146 instead of 154. I think the factory temp calibration builds in an offset so actual temp in the mash is close-ish to correct. I just wish this would have been communicated so we could work around it vs having to figure it out the hard way.

I also want to point out the bottom probe seems to pickup a lot of extra thermal mass from the surrounding base metal. Instead of measuring the wort temp right away, it seems to react much more slowly as the whole base warms up. Proper thermal isolation would let it actually measure wort temp in real time, and let the control algorithm actually work, as opposed to acting just as a thermal safety, which is pretty much all it is doing right now.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

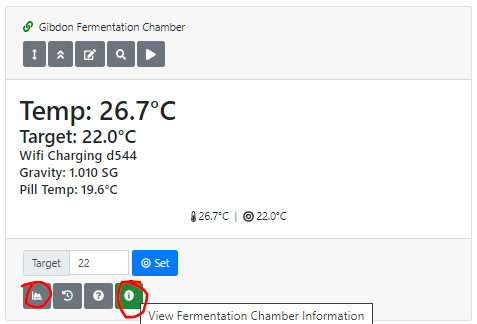

I am interested in the temp number of the rapt bluetooth thermometer on my phone not in the compleet graph.

I just finished up my third brew 5 gal batch with the 65L 220V Brewzilla and everything went well except I am still having trouble with overshooting mash temps. I'm mashing in and letting the mash settle for 10 min before turning the pump on with the ball valve throttling the flow quite a bit. I've watched the Kegland and David Heath videos about setting up the PID. I've dropped the P value to 0.310 and it will still go 3 degrees C over my set temp. I know that the probe is at the bottom by the heating elements so the core temp of the mash is probably a degree or so lower than the stated value. I guess I'll probably just try dialing back the wattage to the heating elements. I plan to get the bluetooth thermometer and probably the heat exchangeer dish when they're available in the US. Anyone have any other tips to avoid overshooting?

I understand everything that is being said in your comments. I had tremendous ploblems with two controllers and on the final controller I continued to have calibration issues. I tried PID and had even more problems. I was getting wild errors of under and over temps. The ranges were ranges were from -62F to +797F. All temps not possible with this type of equipment. Out of frustration, I decided that since this was designed as metric unit I would recalibrate in metric. I did not care about the lower calibration since that is out of the brewing range. I went to Calibration 2 and worked on the boiling point. Once there, two line items came up in the calibration showing the potential output the two elements and the hypothetical temp set for the boil point on each one. In effect, with 2 gallons of water in the kettle and the heating elements on, I was able to adjust the probe reading to match the two element reads. As a constant, the probe always read 100C. The challenge was to get the two elements to reconize what is a true boil temp. Without going into the details of the procedure I used, I was able to get the two element reading to recognize and hold at 100C to match the constant that the probe has of 100C.

I know this works. In the last three brew sessions I have done a two step mash and verified my temps through the steps by using my analogue temp probe. My probe is long enough to measure through the entire mash bed. Temps throughout the mash were consitent to the required mash temp within 0.1C from the bottom of the mash bed to the top of the mash bed. By keeping my hysterisis at 0.1C kept the elements from over shooting the mark. Once I got my mash to temp I was able to maintain its temperature in both steps by adjusting my wattage accordingly to either maintain or raise the bed temp.

One more item to note: I could not get Bluetooth to function on these controllers or the RAPT portal. As long as I do everything manually It works very well. The main reason I went with the Gen4 was because I no longer had the room where I live to continue to use my three tub all grain system that I had been using for years. From that perspective, even running maually I am ahead of the game.

Th

Thanks for your advice SkyPie, we're thinking along similar lines.

Watched David Heath's YouTube video's on hysteresis and knocked that down and it did improve things a little but I'm still getting overshoots. I agree there's probably an effect of thermal mass causing the temp. to continue rising once the elements switch off, I find I'm setting a target temp a couple of degrees below my actual target.

I also tried dialling back the power % in an attempt to reduce the overshoots but like you was concerned about

the effect of the frequent switching of the relay on the lifespan of components. I have a jacket on the brewery and

mash indoors but there's a lot of temp fluctuation compared to accounts I've read of simple BIAB techniques reporting a drop of 2 degrees if you wrap your kettle in a blanket and leave it for an hour, maybe I shouldn't believe everything I read on the internet?

Will have a look at PID settings as you advise before my next brew, fortunately I don't seem to need to re-calibrate the sensor.

Cheers!

ss causing the temp. to continue rising once the elements switch off, I find I'm setting a target temp a couple of degrees below my actual target.

I also tried dialling back the power % in an attempt to reduce the overshoots but like you was concerned about

the effect of the frequent switching of the relay on the lifespan of components. I have a jacket on the brewery and

mash indoors but there's a lot of temp fluctuation compared to accounts I've read of simple BIAB techniques reporting a drop of 2 degrees if you wrap your kettle in a blanket and leave it for an hour, maybe I shouldn't believe everything I read on the internet?

Will have a look at PID settings as you advise before my next brew, fortunately I don't seem to need to re-calibrate the sensor.

Cheers!

I understand everything that is being said in your comments. I had tremendous ploblems with two controllers and on the final controller I continued to have calibration issues. I tried PID and had even more problems. I was getting wild errors of under and over temps. The ranges were ranges were from -62F to +797F. All temps not possible with this type of equipment. Out of frustration, I decided that since this was designed as metric unit I would recalibrate in metric. I did not care about the lower calibration since that is out of the brewing range. I went to Calibration 2 and worked on the boiling point. Once there, two line items came up in the calibration showing the potential output the two elements and the hypothetical temp set for the boil point on each one. In effect, with 2 gallons of water in the kettle and the heating elements on, I was able to adjust the probe reading to match the two element reads. As a constant, the probe always read 100C. The challenge was to get the two elements to reconize what is a true boil temp. Without going into the details of the procedure I used, I was able to get the two element reading to recognize and hold at 100C to match the constant that the probe has of 100C.

I know this works. In the last three brew sessions I have done a two step mash and verified my temps through the steps by using my analogue temp probe. My probe is long enough to measure through the entire mash bed. Temps throughout the mash were consitent to the required mash temp within 0.1C from the bottom of the mash bed to the top of the mash bed. By keeping my hysterisis at 0.1C kept the elements from over shooting the mark. Once I got my mash to temp I was able to maintain its temperature in both steps by adjusting my wattage accordingly to either maintain or raise the bed temp.

One more item to note: I could not get Bluetooth to function on these controllers or the RAPT portal. As long as I do everything manually It works very well. The main reason I went with the Gen4 was because I no longer had the room where I live to continue to use my three tub all grain system that I had been using for years. From that perspective, even running maually I am ahead of the game.

eat contribution to this thread. Now I understand why the bluetooth thermometer is improving my brewing so much. The build in probe in this way is only a guardrail.

And in another Kegland post "At the end of the day the more important temperature to be hitting is in the core of your malt pipe ... So when you understand this you generally come back to realizing the necessity of a second probe in the core of the malt pipeYes I would agree with that. The bluetooth probe takes the core malt pipe temp which is really the main temp you are concerned about and it's been one of the main benefits of the Gen 4 model. I know on this forum we have a lot of discussion about getting the displayed temp for the probe down the bottom of the boiler to be very even with PID and have "no overshoot" but this should not be your objective at all.

When you use the bluetooth probe you have the ability to target the temp in the core of the malt pipe which is actually what matters. What you actually want to do is specifically overshoot the temp at the bottom of the boiler where the element is (within the threshold setting) so you can lift the core malt pipe temp to exactly what it needs to be.

I would not be surprised if our other competitors ... eventually have another probe that goes into the core of the malt pipe too as it's simply a better way to brew and two probes give you the ability to target the "real" mash temp.

Dont get me wrong, it's still important to have a probe down the bottom near the element. It's also important to have a suitable "threshold" setting so this temperature at the bottom of the boiler doesnt get too hot, but for some reason in this discussion we seem to be focussing on this particular probe a bit too much in my opinion as this exact temp is less relevant to the whole process especially if you use the second bluetooth probe.

This is the most frustrating part for me as well...I finally was able to get the neoprene jacket after waiting for 6 months, and now I'm still stuck waiting on the bluetooth thermometer and diverter plate.I have the 35 liter Gen 4 system, but have similar issues. I think a lot of these issues will be mostly resolved when the bluetooth thermometer and the diverter plate that fits under the bottom screen become available in North America (Canada as well as the US). I just can't understand why it takes three-quarters to a full year to get these devices here! Sure you can order direct from Kegland, but the shipping fees are just too much.

And in another Kegland post "At the end of the day the more important temperature to be hitting is in the core of your malt pipe ... So when you understand this you generally come back to realizing the necessity of a second probe in the core of the malt pipe

Thank you for your candid response Kegland. I can appreciate that the core malt pipe temp. is what matters, you're supporting my point that the Gen 4 I bought isn't the autonomous, complete solution I thought it was and it won't be until I get the Bluetooth probe, since you describe it as a "necessity".

I understand there may have been commercial reasons for releasing the new model Gen 4 when you did but, in the interests of customer relations, as others have said on here, how about a bit of support for us early adopters rather than expecting us to pay the full retail price for what you describe above as a "necessity" and "one of the main benefits of the Gen 4 model".

I spent many hours researching different All in One solutions prior to purchasing the Gen4 last year, here in the UK and the satisfaction and pleasure that so many users expressed in their Gen 3s was what clinched it for me, in addition to a level of control and consistency better than I could achieve with a stove-top set-up.

I'm not immune to the allure of shiny add-ons, hoping to move good performance to even better levels, it's a common feature of most hobbies and brewing is no exception, I'm just disappointed to discover that my basic model, without the add-ons, lacks the ability to monitor the core mash temp, given the importance attached to this and it can't control the wort temperature without overshooting my target temperature leading, I assume, to overheating of some of my malt as it recirculates.

And in another Kegland post "At the end of the day the more important temperature to be hitting is in the core of your malt pipe ... So when you understand this you generally come back to realizing the necessity of a second probe in the core of the malt pipe

Thank you for your candid response Kegland. I can appreciate that the core malt pipe temp. is what matters, you're supporting my point that the Gen 4 I bought isn't the autonomous, complete solution I thought it was and it won't be until I get the Bluetooth probe, since you describe it as a "necessity".

I understand there may have been commercial reasons for releasing the new model Gen 4 when you did but, in the interests of customer relations, as others have said on here, how about a bit of support for us early adopters rather than expecting us to pay the full retail price for what you describe above as a "necessity" and "one of the main benefits of the Gen 4 model".

I spent many hours researching different All in One solutions prior to purchasing the Gen4 last year, here in the UK and the satisfaction and pleasure that so many users expressed in their Gen 3s was what clinched it for me, in addition to a level of control and consistency better than I could achieve with a stove-top set-up.

I'm not immune to the allure of shiny add-ons, hoping to move good performance to even better levels, it's a common feature of most hobbies and brewing is no exception, I'm just disappointed to discover that my basic model, without the add-ons, lacks the ability to monitor the core mash temp, given the importance attached to this and it can't control the wort temperature without overshooting my target temperature leading, I assume, to overheating of some of my malt as it recirculates.

Hi, so if PID is not really necessary what settings do you recommend/use to control the mash temp? ThanksIn my opinion PID is really not necessary for mashing. If you do finely tune the PID you can get to the point where the temperature is kept at the base of the brewery perfectly evenly and this takes some practice with PID tuning to do this but if you adjust the pump speed, do a different sized batch or change other conditions then you technically should be re-tuning the PID.

With that said you really do have to ask "is it actually that useful to very accurately control the temperature at the base of the boiler". At the end of the day the more important temperature to be hitting is in the core of your malt pipe and in reality if the temperature fluctuates on the base of the boiler that is prefectly fine. Most of the enzymatic reaction will be happening in the malt pipe not in the very small amount of wort at the bottom of the brewery where the probe is located. So when you understand this you generally come back to realizing the necessity of a second probe in the core of the malt pipe.

If you enjoy the process of really honing in your PID settings and mastering the art of this control process I think it can be quite enjoyable to work with the PID but if you just want a short cut to making great beer with minimal effort I would say the PID is not required.

so i've got the rapt app on my phone, and i'm getting alerts- but not the ones i want and only ones i didnt ask for.....Hello SanPancho. I think we might have missed this comment previously regarding notifications.

If you want to get push notifications you need to install the app on your phone. (please make sure it's updated to the latest version). This app is a webview app that renders the RAPT portal into your phone screen better but it also allows push notifications to occur. Once you have the app on your phone installed you can use your phone settings to change your notification settings on your phone to make an audible sound that you hear for instance but this is not controlled by our app it's a setting on your phone.

Android:

RAPT Android APP

iPhone:

RAPT Apple Device

What we really need is brewfather integration for the mash.so i've got the rapt app on my phone, and i'm getting alerts- but not the ones i want and only ones i didnt ask for.....

i have a preboil profile set to send me an alert when it hits 180F. didnt happen. what did it do instead? when i manually shut off the profile, it sent me an alert that the profile was finished........????

i went back, rechecked all my profile info online, made sure mobile number and email address were correct, etc. then went to mash profile. hochkurz mash, 145, 158, then 170. its supposed to alert me when it hits 170 for mashout. again, didnt happen.

but when i ended the profile manually on the unit......... it sent me an alert telling me the profile finished.

i checked for new firmware, have latest rapt app version, notifications are allowed on my phone, made sure all my profile stuff is there and correct.

i only upgraded to v4 in order to be able to get wifi/mobile alerts while brewing, and 6 months after i raised the issue it was supposedly "fixed" but now that im brewing its pretty clear there is no practical alert function.

how do we fix this?

What we really need is brewfather integration for the mash.

I don't even use the rapt app for my pill anymore, brewfather's UI is quite a bit better and integrates the whole process really well.

And the notifications work...

Hi, so if PID is not really necessary what settings do you recommend/use to control the mash temp? Thanks

so i've got the rapt app on my phone, and i'm getting alerts- but not the ones i want and only ones i didnt ask for.....

i have a preboil profile set to send me an alert when it hits 180F. didnt happen. what did it do instead? when i manually shut off the profile, it sent me an alert that the profile was finished........????

i went back, rechecked all my profile info online, made sure mobile number and email address were correct, etc. then went to mash profile. hochkurz mash, 145, 158, then 170. its supposed to alert me when it hits 170 for mashout. again, didnt happen.

but when i ended the profile manually on the unit......... it sent me an alert telling me the profile finished.

i checked for new firmware, have latest rapt app version, notifications are allowed on my phone, made sure all my profile stuff is there and correct.

i only upgraded to v4 in order to be able to get wifi/mobile alerts while brewing, and 6 months after i raised the issue it was supposedly "fixed" but now that im brewing its pretty clear there is no practical alert function.

how do we fix this?

Thanks for the reply.I will answer this question in two parts:

If you are using the Bluetooth probe

If you are using Bluetooth probe you just need to make sure that it's correctly paired and inserted into the core of the malt pipe. I would also set the allowed sensor differential to 10C. That is pretty much it and this works great.

If you are not using the Bluetooth probe

I would set the mash temp on the display and just be aware that this is giving you the temp reading on the base of the unit (just like all other single vessel breweries). I would be concerned about any minor fluctuation on the displayed temperature as this is not the core malt pipe temp. I would set the pump recirculation to 35% and then just wait for the temperature to equalize. Over time the core malt pipe will get closer and closer to the set temp on the display but be aware that this takes some time.

Alternatively if you are in a bit more of a hurry set the temp on the display slightly hotter (like you would any RIMS system) than what you want your core malt pipe temp to be and when the malt pipe temp is getting close to the target then back the temperature off a bit.

Hello Neldog. Can you please look at this calibration video here:

You have said that "I did not care about the lower calibration since that is out of the brewing range". The two point calibration is not about this. In order to establish the most accurate "beta" value you require two points for this to be calucated. You do not need to calibrate point 1 at 0.0C. This is just the default temperature for point one and its easy for customers to establish 0.0C as this is the temperature of ice water mixture. With that said if you wanted to calibrate point 1 at 65C (149F) you can use this temp for point 1 instead and you will have an even more accurate cuve for your application.

If you decide to skip point 1 that is fine but please be aware that if you do this then we are unable to actually calculate the beta value. So as a result of this only an offset can be used and this will be far less accurate than using two point calibration method. Its really better explained in the video so I would encourage you to watch this first.

I specifically purchased the Brewzilla because of the mashing capabilities. I cannot brew indoors (no pracital place where I can vent the steam) and the climate here only allows me to boil outdoors with the Brewzilla for perhaps only 1/3 of the year. Thus I use the Brewzilla primarily as a mash machine. Also, since I primarily brew lagers, I purchased the Brewzilla for its ability to do step mashes and the ability to set the temperature regime and walk away. Obviously, this has been a major disapointment, as I have to constantly babysit the Brewzilla during the majority of the hour to an hour and a half mash. I have to make manual adjustments constantly, every few minutes, until everything has finally come into balance, which could be more than 20 or 30 minutes. After that, only a few adjustments need to be made every now and then.I was considering purchasing a brewzilla since my old cooler mash tun is nearing it's end of life. I think at a minimum I will wait until the heat exchanger plate and bluetooth thermometers are readily available in the US and some people have put them through their paces. A large part of the draw was being able to control mash temps precisely, but it feels like this would actually be a step backwards from my cooler where I only lose about 1-1.5 degrees F if i don't open it during the mash.

A couple of other questions, can someone measure the diameter of the opening? I have a Jaded Hydra that is 10.5" across and I am hoping it will fit.

Second, what is the largest grain bill someone here has managed to do successfully? I regularly brew Belgian tripels and Belgian dark strongs that have a grainbill around 22-23lbs and I am wondering if this would require the boiler extension.

Thanks,

I tried to run this using PID and got nothing but low and hi temp errors. P was set for .48, and I was set for .0020. Immediately I statred get one alarm after another. I adusted my setting to see if I could eliminate the alarms. Nothing worked. I turned off PID and went back to my settings.. I changed calibration 1 to 64C.Since I only brew in the Brewzilla, I would expect my Cal1 temperature lowest point to be 64C. Since this is my lowest potential mash in do you want me to go back to Cal 1 and enter this value?

Again, it involves using a LOT of water.Brewing indoors is fine if you get or make a condenser.

Same thing happened to me on Sunday. I think I may have had the screen upside down?Doing my first real batch now, and while lifting the malt pipe, the bottom screen came right out the bottom. So now I get to figure out how to separate and transfer everything. In the meantime, a nice long mash, it is... JFC.

edit - at least the bottom screen seems to have stopped the grains from getting to the pump, so I'll just push the wort into a few carboys, then clean, reset, and start the boil.

I haven't found any literature that claims directionality, but I would assume that having the screen angled with the "bulge" down seems right. I have a hard time imagining the thing slipping loose, but apparently 25 lbs of grain (65l version) plus water was a bit too much for it. Seems ridiculous for it be able to come out.Same thing happened to me on Sunday. I think I may have had the screen upside down?

I even had my new pulley system in place and the on first pull, the screen let loose. Was expecting a little bit more of a fightI haven't found any literature that claims directionality, but I would assume that having the screen angled with the "bulge" down seems right. I have a hard time imagining the thing slipping loose, but apparently 25 lbs of grain (65l version) plus water was a bit too much for it. Seems ridiculous for it be able to come out.

I also have not seen official word, but most things like this go bulge-up in an effort to shed loading outwards.I even had my new pulley system in place and the on first pull, the screen let loose. Was expecting a little bit more of a fight

Yeah, like the arch in a dam. I'll try that next time, cause the extra hour+ of running around, problem solving, cleaning, and lack of any meaningful sparge was a bit of a downer.I also have not seen official word, but most things like this go bulge-up in an effort to shed loading outwards.

I'm kind of curious if it wasn't seated when you lifted. Do you lift quickly?

And is yours a 65L?

Thanks for the reply.

As a general feed back, I think the instructions and info on your website (unless I've missed it) are not great. I think it would be great if you made a video or instructions with a default sort of brew on how the system is designed to be used. I've been brewing for years but on a 3 vessel system so the AIO systems were a bit of a mystery to start with. I certainly wouldn't recommend this one to a new brewer yet.

Thanks

I also have not seen official word, but most things like this go bulge-up in an effort to shed loading outwards.

I'm kind of curious if it wasn't seated when you lifted. Do you lift quickly?

And is yours a 65L?