I was thinking the same thing. I for one am appreciative KegLand visits this forum and tries to offer their assistance. We all know Rapt is new and some patience should be expected.Classy response to a fairly incendiary post. Appreciate the work you guys are doing. Thank you.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brewzilla Gen4 Discussion/Tips Talk

- Thread starter stealthfixr

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

agentbud

Well-Known Member

DittoI was thinking the same thing. I for one am appreciative KegLand visits this forum and tries to offer their assistance. We all know Rapt is new and some patience should be expected.

I read all about temperature calibration , i watch the video 3 times.

I done the calibration 3 times without success.

I just cant calibrate the temperature so that it shows correct values.

And it is off with most important temperature around 60-80C.

Maybe would help if I calibrate it on 1 point around 60C and 2 point around 75C ???

Or if we have option like on previous models and some of the others manufacturer to change the temperature with + and - to the correct level.

Hello Morpheusda. I am sure once you do the calibration the actual probe will be accurate.

When you say "not correct" in reference to what? I think it's important to understand the placement of the probe. The probe on the BrewZilla is down the bottom of the BrewZilla and the temperature here I am quite sure will be accurate if you have done the calibration. With that said with all breweries you will get different temperature readings if you take measurements from other parts of the brewery. All breweries have a differential at the top, middle and bottom and in the core of the malt pipe. If you recirculate for long enough and also insulate the boiler you will find the temperatures get closer and closer together. With that said one of the major improvements to the Gen 4 was bluetooth and the ability to pair up to 8 bluetooth devices.

If you really want to achieve the best control I highly recommend using the bluetooth probe that gives you a secondary probe so you can force the brewery to heat up the core of the malt pipe to the desired temperature and get to this point faster. This was covered in this video here:

You can definitely use the brewery fine without the bluetooth probe but once you use the probe I am confident you will see the value in this.

We are also looking to change the firwmware in the future so that you can put the bluetooth probe into the output of your counter flow chiller for instance and then control the pump speed to target a specific output temperature of the brewery so it will be useful for other applications like this. The same probe will also be useful in some of our new distillation devices where multiple temperature reedings are also necessary.

Thanks for that I appreciate it. KegLand is only 4 years old so far but hopefully with time we are able to win you guys over. We definitely are always keen to hear what you say irrespective of if it's positive or negative and many of the new products we make are a result of these forum based conversations.Ditto

While this did not work on my dead controller, this is very good information to release to users and have posed on this site.

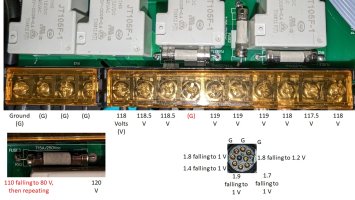

Regarding this unit making heat with the dead controller unplugged, I took some voltage readings before boxing it up to return. A few things that stood out when compared to the replacement unit:

- Post #4 on the big block was grounded out unstead of showing 120 volts.

- The voltage on the RV2 side of FUSE3 started at 110 volts, then quickly fell to 80 volts before returning to 110 volts to repeat the cycle. This cycling was continuous.

- Pins 1, 2, 3, 4 and 8 on the controler plug were receiving volts instead of millivolts. They exibited the same cycling behavior as FUSE3, except the voltage would start at 1.4 to 1.9 volts, then quickly fall to 1 volt. The specifics are inthe attachment.

Hopefully Kegland and anyone with electrical knowledge can make sense of this and diagnose the suspected failure point(s). It will not help with this unit, but it could potentially point to corrective measures users might take if they experience this same problem down the road when their unit is out of warrenty. It also might give clues for how to prevent this from happening as new units are manufactured (e.g. design modification, modifying the testing SOP, etc.).

Also with regards to button presses to reset the controller.

If you want to delete your settings (this deletes non-volatile memory storage (NVS) that contain settings)

1. Unplug power

2. Hold down the up and down arrow plug while plugging the cable back into the power point

If you want to get into the boot menu you can get options to rollback firmware, upgrade firmware, reset the controller, delete NVS or do other basic tasks you can get into this menu by:

1. Unplug power

2. Hold down the up down arrows and also the cycle and enter button all at the same time while plugging into the power point.

(this is really best done with a friend to help you)

Regarding this unit making heat with the dead controller unplugged, I took some voltage readings before boxing it up to return. A few things that stood out when compared to the replacement unit:

- Post #4 on the big block was grounded out unstead of showing 120 volts.

- The voltage on the RV2 side of FUSE3 started at 110 volts, then quickly fell to 80 volts before returning to 110 volts to repeat the cycle. This cycling was continuous.

- Pins 1, 2, 3, 4 and 8 on the controler plug were receiving volts instead of millivolts. They exibited the same cycling behavior as FUSE3, except the voltage would start at 1.4 to 1.9 volts, then quickly fall to 1 volt. The specifics are inthe attachment.

Hopefully Kegland and anyone with electrical knowledge can make sense of this and diagnose the suspected failure point(s). It will not help with this unit, but it could potentially point to corrective measures users might take if they experience this same problem down the road when their unit is out of warrenty. It also might give clues for how to prevent this from happening as new units are manufactured (e.g. design modification, modifying the testing SOP, etc.).

Attachments

First full batch brew on the Gen 4 65. If you are experienced on the Gen 3 35, I wanted to add to the knowledge base with somethings I learned.

1. Manually update the firmware when you are doing your first cleaning.

The update check interval is unknown, but others have reported the controller picking up an update mid brew. I did receive a prompt during my post brew clean up, but it just informed me that the firmware was up to date.

2. Don’t forget the smaller dead space.

I just doubled my normal strike water volume and grain bill, then had a face palm moment near the end of mashing in when it was super soupy. I was used to mashing at 1.6qt/lb., so I ended up with the equivalent of mashing with 2qt/lb. in a Gen 3. The extended malt pile had enough room to easily handle 12 gallons + 29 pounds of grain without over flowing out the side holes, which was nice. My brewhouse efficiency ended up being 15 points higher, so maybe I will stick with the soupy mash now that I have the room to accommodate it.

3. To reduce the potential of a plugged pump, rework the plumbing to move the T before the pump.

If there is blockage, you may be able to clear it by opening the side valve. If not, you can still draw your wort off with out the pump. I stopped recirculating at mash out to let any heavy stuff settle, then after a few minutes I drew off the sediment before I hit the boil button.

4. If you have your process down on a Gen 3, don't mess with the pump percentage.

As others have said, just throttle the flow like you are used to with the valve. Adding pump cycling to the equation while mashing is just going to complicate matters.

5. Check that the burner is still on after you adjust the temperature (assuming this is what you want).

You can adjust the temperature on the fly, which is cool. However, I the Gen 3 has me conditioned to hit the play button after I adjust the temperature, so the first few times I did this on the Gen 4 I inadvertently turned the burners off. If you see the temperature start to fall and you have a what the hell is up with that thought, your muscle memory might have gotten the best of you.

6. The quickest way to adjust the heating percentage mid brew is through the portal.

I actually have not found a way to do this from the controller yet, so in my case it was the only way.

7. The Gen 4 65 recovers from an impending boil over quicker than a Gen 3 35 L.

This thing makes a serious rolling boil and it respond quickly to killing the burners. If you were 2 seconds from a boil over in a Gen 3 and you hit the power, it was already too late. The Gen 4 65 seems to respond much quicker to killing the power. Perhaps it is a combination of the larger surface area of the wort combined with the larger surface area of the new elements or it is just my perception.

8. The concave center drain is a blessing and a curse.

If the volume is down near the bottom screen level, the concave drain creates a pretty impressive vortex that actually starts to suck air in to the pump. If you do not throttle the flow, the pump will cavitate before all the liquid is drained - at least with the reworked pluming.

Also, every last bit break material that makes its way through bottom filter is going into your fermenter or in my case, into my hop back to plug it up after 7 gallons. I am not sure yet how to mitigate this most effectively when using a hop back, but I am sure others will come up with good solutions. Next brew I am going to try just draining some wort and break off the side before I start pumping.

Overall, there is more good than annoying with the Gen 4 once you get it up and running. Every set up has its own quirks, but you adjust and tweak your process.

1. Manually update the firmware when you are doing your first cleaning.

The update check interval is unknown, but others have reported the controller picking up an update mid brew. I did receive a prompt during my post brew clean up, but it just informed me that the firmware was up to date.

2. Don’t forget the smaller dead space.

I just doubled my normal strike water volume and grain bill, then had a face palm moment near the end of mashing in when it was super soupy. I was used to mashing at 1.6qt/lb., so I ended up with the equivalent of mashing with 2qt/lb. in a Gen 3. The extended malt pile had enough room to easily handle 12 gallons + 29 pounds of grain without over flowing out the side holes, which was nice. My brewhouse efficiency ended up being 15 points higher, so maybe I will stick with the soupy mash now that I have the room to accommodate it.

3. To reduce the potential of a plugged pump, rework the plumbing to move the T before the pump.

If there is blockage, you may be able to clear it by opening the side valve. If not, you can still draw your wort off with out the pump. I stopped recirculating at mash out to let any heavy stuff settle, then after a few minutes I drew off the sediment before I hit the boil button.

4. If you have your process down on a Gen 3, don't mess with the pump percentage.

As others have said, just throttle the flow like you are used to with the valve. Adding pump cycling to the equation while mashing is just going to complicate matters.

5. Check that the burner is still on after you adjust the temperature (assuming this is what you want).

You can adjust the temperature on the fly, which is cool. However, I the Gen 3 has me conditioned to hit the play button after I adjust the temperature, so the first few times I did this on the Gen 4 I inadvertently turned the burners off. If you see the temperature start to fall and you have a what the hell is up with that thought, your muscle memory might have gotten the best of you.

6. The quickest way to adjust the heating percentage mid brew is through the portal.

I actually have not found a way to do this from the controller yet, so in my case it was the only way.

7. The Gen 4 65 recovers from an impending boil over quicker than a Gen 3 35 L.

This thing makes a serious rolling boil and it respond quickly to killing the burners. If you were 2 seconds from a boil over in a Gen 3 and you hit the power, it was already too late. The Gen 4 65 seems to respond much quicker to killing the power. Perhaps it is a combination of the larger surface area of the wort combined with the larger surface area of the new elements or it is just my perception.

8. The concave center drain is a blessing and a curse.

If the volume is down near the bottom screen level, the concave drain creates a pretty impressive vortex that actually starts to suck air in to the pump. If you do not throttle the flow, the pump will cavitate before all the liquid is drained - at least with the reworked pluming.

Also, every last bit break material that makes its way through bottom filter is going into your fermenter or in my case, into my hop back to plug it up after 7 gallons. I am not sure yet how to mitigate this most effectively when using a hop back, but I am sure others will come up with good solutions. Next brew I am going to try just draining some wort and break off the side before I start pumping.

Overall, there is more good than annoying with the Gen 4 once you get it up and running. Every set up has its own quirks, but you adjust and tweak your process.

Last edited:

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

While this did not work on my dead controller, this is very good information to release to users and have posed on this site.

Regarding this unit making heat with the dead controller unplugged, I took some voltage readings before boxing it up to return. A few things that stood out when compared to the replacement unit:

- Post #4 on the big block was grounded out unstead of showing 120 volts.

- The voltage on the RV2 side of FUSE3 started at 110 volts, then quickly fell to 80 volts before returning to 110 volts to repeat the cycle. This cycling was continuous.

- Pins 1, 2, 3, 4 and 8 on the controler plug were receiving volts instead of millivolts. They exibited the same cycling behavior as FUSE3, except the voltage would start at 1.4 to 1.9 volts, then quickly fall to 1 volt. The specifics are inthe attachment.

Hopefully Kegland and anyone with electrical knowledge can make sense of this and diagnose the suspected failure point(s). It will not help with this unit, but it could potentially point to corrective measures users might take if they experience this same problem down the road when their unit is out of warrenty. It also might give clues for how to prevent this from happening as new units are manufactured (e.g. design modification, modifying the testing SOP, etc.).

I have not heard of anything like this before. If you get voltage drop particularly when under load this is usually an indication that the wiring from between the elements and the power point and insufficient thickness or have too high resistance. The most common issue that we see is if customers use a long extension cable especially if the cable is thin or getting too hold and the copper inside the cable is not in good condition. This power loss is only evident under load. If you notice the brewery has low power then you may want to also check the extension cable or cable joins.

The measured voltages off the plug also seem a bit strange and this is not normally what we would expect either so something seems wrong but we need to get the unit back to bench test as it's very difficult to know what the issue is based on what you have said so far.

bjhbrew

Well-Known Member

- Joined

- Oct 15, 2016

- Messages

- 159

- Reaction score

- 90

Hey guys. It seems that there has been some "mystery" regarding how the calibration process works so we made this video to explain the process for you in more detail. Let us know if there is anything that we have missed:

@KegLand Thanks for posting this video. I was finding that the temperature probe in my gen 4 BrewZilla was reading about 4 degrees lower than actual temperature when mashing but then was reading a few degrees too high when at a boil. I followed the steps in the video to set 2 calibration points and the accuracy seems to be much closer. I chose 50f and then 212f (boiling) as my two set points if that matters. Now I'm finding that it's still off about 2 degrees when in the mashing range (display reads lower than actual temp). I'm curious if there is a way to alter the curve between the two data points? Or, should I just choose two new points at the bottom and top of the mashing range? I appreciate any help!

@KegLand Thanks for posting this video. I was finding that the temperature probe in my gen 4 BrewZilla was reading about 4 degrees lower than actual temperature when mashing but then was reading a few degrees too high when at a boil. I followed the steps in the video to set 2 calibration points and the accuracy seems to be much closer. I chose 50f and then 212f (boiling) as my two set points if that matters. Now I'm finding that it's still off about 2 degrees when in the mashing range (display reads lower than actual temp). I'm curious if there is a way to alter the curve between the two data points? Or, should I just choose two new points at the bottom and top of the mashing range? I appreciate any help!

Can you please send a photo of how you are measuring the temperature difference?

We do not have plans to make it possible to change the curve but I doubt that is the issue. I think it will have more to do with the difference between the probe position in the base of the boiler and the probe that you are using to measure the temperature.

JoepH

Active Member

I don’t see my rapt bluetooth thermometer in the portal. Is this not yet available or do I miss something? On the display it works perfectly.

morpheusda

Member

Hello Morpheusda. I am sure once you do the calibration the actual probe will be accurate.

When you say "not correct" in reference to what? I think it's important to understand the placement of the probe. The probe on the BrewZilla is down the bottom of the BrewZilla and the temperature here I am quite sure will be accurate if you have done the calibration. With that said with all breweries you will get different temperature readings if you take measurements from other parts of the brewery. All breweries have a differential at the top, middle and bottom and in the core of the malt pipe. If you recirculate for long enough and also insulate the boiler you will find the temperatures get closer and closer together. With that said one of the major improvements to the Gen 4 was bluetooth and the ability to pair up to 8 bluetooth devices.

If you really want to achieve the best control I highly recommend using the bluetooth probe that gives you a secondary probe so you can force the brewery to heat up the core of the malt pipe to the desired temperature and get to this point faster. This was covered in this video here:

You can definitely use the brewery fine without the bluetooth probe but once you use the probe I am confident you will see the value in this.

We are also looking to change the firwmware in the future so that you can put the bluetooth probe into the output of your counter flow chiller for instance and then control the pump speed to target a specific output temperature of the brewery so it will be useful for other applications like this. The same probe will also be useful in some of our new distillation devices where multiple temperature reedings are also necessary.

I calibrated it 3 times and still no success.In some range the temp is correct but in some more important temp range (60 -80C) it is not acurate it is still 2 degrees lower.As reference I use inkbird ITC 308 digital thermometer and put the probe near brewzilla temp probe so that there is no difference in temperature between two probes and brewzilla still reads 2 degrees lower.

After 3 calibration.

Dont know what to do.

hmmm... how did you swing that?

Just got frustrated with MoreBeer not listing it, so I did a Google search and found this link: Heat Exchange Dish | BrewZilla Gen4 | 65L | BeerCo.com.au. It arrived at my US address about 6 days after AUS Express shipping, not bad at all. BUT, paid almost as much in shipping as I did for the item.

I have not brewed with it yet, but will post back when I do. It loosely fit onto the bottom screen nicely, but then warped slightly when tightened down. No instructions. I believe a nut is still needed on the backside of the bottom screen, and the wingnut tightens to that. Without it, you can tighten the HED way too much, warping it even further.

I did not know there was an Apple RAPT app out yet, very helpful. Thank you, Kegland! Now I can monitor my brew when not hovering in front of the mash, and more.iPhone:

RAPT Apple Device

I do appreciate your presence here, giving us straight feedback. My BZ3 65L brewed three, local Best of Show beers last year, and I suspect the BZ4 will do the same or better if I do my part right. I'll take my BZ AIO any day over my old, three vessel setup.

agentbud

Well-Known Member

Yes, definitely let us know how it goes after your next brew.Just got frustrated with MoreBeer not listing it, so I did a Google search and found this link: Heat Exchange Dish | BrewZilla Gen4 | 65L | BeerCo.com.au. It arrived at my US address about 6 days after AUS Express shipping, not bad at all. BUT, paid almost as much in shipping as I did for the item.

I have not brewed with it yet, but will post back when I do. It loosely fit onto the bottom screen nicely, but then warped slightly when tightened down. No instructions. I believe a nut is still needed on the backside of the bottom screen, and the wingnut tightens to that. Without it, you can tighten the HED way too much, warping it even further.

BTW - MoreBeer now says they expect arrival of the HEDs on Mar 29 with purchasing available the following week.

I don’t see my rapt bluetooth thermometer in the portal. Is this not yet available or do I miss something? On the display it works perfectly.

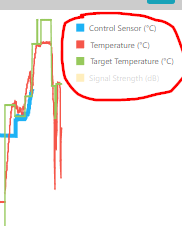

I am not sure if you are aware of this but if you click the magnifying glass you can open up the detailed graph and then click on these coloured squares to toggle on/off certain parts of the graph. If you have paired your bluetooth probe with your BrewZilla you will see "Control Sensor" and "Temperature". These are the inbuilt probe and the bluetooth probe.

Just got frustrated with MoreBeer not listing it, so I did a Google search and found this link: Heat Exchange Dish | BrewZilla Gen4 | 65L | BeerCo.com.au. It arrived at my US address about 6 days after AUS Express shipping, not bad at all. BUT, paid almost as much in shipping as I did for the item.

I have not brewed with it yet, but will post back when I do. It loosely fit onto the bottom screen nicely, but then warped slightly when tightened down. No instructions. I believe a nut is still needed on the backside of the bottom screen, and the wingnut tightens to that. Without it, you can tighten the HED way too much, warping it even further.

The heat exchanger dish has taken a bit longer to get over to America but good to see that this has arrived. The heat exchanger dish forces the liquid wort to recirculate over the probe at higher velocity so you might find that it gives you more accurate temperature reading.

As morpheusda has said he seems to get a 2degrees difference in the 60-80C range but I am assuming this is purely due to the temperature differential between the top and bottom of the brewery. It's not that the temperature is incorrect it's simply that at the position where the probe is this is actually the temperature at the base near the edge of the boiler.

The heat exchanger dish does help quite a lot to improve the consistent temperature throughout the brewery and it also speeds up the step mash process as it forces wort over the probe and elements at higher velocity.

I did not know there was an Apple RAPT app out yet, very helpful. Thank you, Kegland! Now I can monitor my brew when not hovering in front of the mash, and more.

I do appreciate your presence here, giving us straight feedback. My BZ3 65L brewed three, local Best of Show beers last year, and I suspect the BZ4 will do the same or better if I do my part right. I'll take my BZ AIO any day over my old, three vessel setup.

Thanks for that. We will try to be more involved in these American forums in future. If we happen to miss anything please send us a PM and we will jump on it and respond.

Just ordered a Kegland RAPT Bluetooth Thermometer from the same place I got the HED from—see the link above if interested. Beerco.au customer service is excellent, by the way.

I just received and built my new 220v, 65l gen 4. I thought it was supposed to have a detachable cord, but this one goes straight through the body with a strain relief grommet. Is this "feature" particular to this model?

Otherwise, I'm excitedly awaiting an extension cord so I can fire this thing up and put it through it's paces.

Otherwise, I'm excitedly awaiting an extension cord so I can fire this thing up and put it through it's paces.

- Joined

- Jan 28, 2013

- Messages

- 3,926

- Reaction score

- 3,026

Otherwise, I'm excitedly awaiting an extension cord so I can fire this thing up and put it through it's paces.

Don't forget to fill with water so it doesn't dry fire!

I just received and built my new 220v, 65l gen 4. I thought it was supposed to have a detachable cord, but this one goes straight through the body with a strain relief grommet. Is this "feature" particular to this model?

Otherwise, I'm excitedly awaiting an extension cord so I can fire this thing up and put it through it's paces.

We have not been able to find a component manufacturer that has a 15amp IEC cable/socket combination that is UL approved for America.

So other countries around the world have the IEC cable unplug but in America we cannot find a supplier yet.

morpheusda

Member

The temperature is measured near the probe on the bottom of the brewzilla with the probe of Inkbird 308, so there is no difference because of different space of unit where the temperature is measured.The heat exchanger dish has taken a bit longer to get over to America but good to see that this has arrived. The heat exchanger dish forces the liquid wort to recirculate over the probe at higher velocity so you might find that it gives you more accurate temperature reading.

As morpheusda has said he seems to get a 2degrees difference in the 60-80C range but I am assuming this is purely due to the temperature differential between the top and bottom of the brewery. It's not that the temperature is incorrect it's simply that at the position where the probe is this is actually the temperature at the base near the edge of the boiler.

The heat exchanger dish does help quite a lot to improve the consistent temperature throughout the brewery and it also speeds up the step mash process as it forces wort over the probe and elements at higher velocity.

It is simply 2C difference in readings.

My question is :

would be temperature reading be right if I calibrate it with 60C and 80C,

because this is the range where we need to have exactly right readings of temperature.

For me does not matter if the boiling temperature is not right, when is boiling it is boiling and I can see it, but mash temperature needs to be right.

tgbruiser

Member

Are you sure the Inkbird 308 is 100% accurate? The spec for it says its accuracy is +2°F/1°C. If the Brewzilla has a similar accuracy, then you could easily see a difference of 2°C between the two if one is reading at the high end and the other is reading at the low end of their tolerance.The temperature is measured near the probe on the bottom of the brewzilla with the probe of Inkbird 308, so there is no difference because of different space of unit where the temperature is measured.

It is simply 2C difference in readings.

My question is :

would be temperature reading be right if I calibrate it with 60C and 80C,

because this is the range where we need to have exactly right readings of temperature.

For me does not matter if the boiling temperature is not right, when is boiling it is boiling and I can see it, but mash temperature needs to be right.

JoepH

Active Member

Thanks, found it. Woodn’t it be easyer if you could see it in the info page?View attachment 814441

I am not sure if you are aware of this but if you click the magnifying glass you can open up the detailed graph and then click on these coloured squares to toggle on/off certain parts of the graph. If you have paired your bluetooth probe with your BrewZilla you will see "Control Sensor" and "Temperature". These are the inbuilt probe and the bluetooth probe.

DuncB

Well-Known Member

Hi it was @Moto that had the problem with their new 65litre brewzilla and that dialogue is occurring.Hey DuncB. Can you please send us the MAC address of your device. If the boiler is boiled dry normally the boil dry switch will be triggered and it's just a matter of waiting for the thermal overload to reset and the unit will work again after this.

If your device was connected to the internet I can use the MAC address to see what is going on but it does sound pretty unusual. Hopefully the data logged to the portal will enable us to see how this happened to you.

For some reason my following of this thread hasn't been updating.

Don't forget to fill with water so it doesn't dry fire!

Mine came with the target temp set to 0c/32f, so no problem there. I filled it anyway, though. Definitely read through the whole thread before turning anything on.

morpheusda

Member

Yes the inkbird is accurate, it is check with another bluetooth temperature sensor and with Inkbird IBT-2X Bluetooth Barbecue Kitchen ThermometerAre you sure the Inkbird 308 is 100% accurate? The spec for it says its accuracy is +2°F/1°C. If the Brewzilla has a similar accuracy, then you could easily see a difference of 2°C between the two if one is reading at the high end and the other is reading at the low end of their tolerance.

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

Wanted to report back and say I tried mashing without the brew bag again the last 2 brews. No matter what I do I get a stuck mash. I've tried adjusting the pump ball valve down to almost as restrictive as it will go and have even tried up to 10% rice hulls. Maybe there is a recommended mill gap that is looser that .032 (aka credit card width). I've tried setting this with a credit and feeler gauge. If it's brew bag or bust I'm ok with it but wanted to see if there were any other recommendations.

Bottoms_Up

Well-Known Member

I'm sticking with a brewbag. I'm currently using an oversized one that I used for my brew kettle in the past, while waiting for the BrewBag people to make me one to specifically fit the 35 liter Gen 4 Brewzilla pipe. I hope to receive it within the next week or two. I use the brewbag twice during each brew - once while in the Brewzilla pipe, and again while in my fermenter when I transfer the wort after boiling. This removes most of the hop, hot, and cold break trub.Wanted to report back and say I tried mashing without the brew bag again the last 2 brews. No matter what I do I get a stuck mash. I've tried adjusting the pump ball valve down to almost as restrictive as it will go and have even tried up to 10% rice hulls. Maybe there is a recommended mill gap that is looser that .032 (aka credit card width). I've tried setting this with a credit and feeler gauge. If it's brew bag or bust I'm ok with it but wanted to see if there were any other recommendations.

JoepH

Active Member

Go for 1,35 mm (metric) and your problems will be over.Wanted to report back and say I tried mashing without the brew bag again the last 2 brews. No matter what I do I get a stuck mash. I've tried adjusting the pump ball valve down to almost as restrictive as it will go and have even tried up to 10% rice hulls. Maybe there is a recommended mill gap that is looser that .032 (aka credit card width). I've tried setting this with a credit and feeler gauge. If it's brew bag or bust I'm ok with it but wanted to see if there were any other recommendations.

deadwolfbones

Well-Known Member

Have you considered doing no-sparge? I found that helped me tremendously (similar mill gap).Wanted to report back and say I tried mashing without the brew bag again the last 2 brews. No matter what I do I get a stuck mash. I've tried adjusting the pump ball valve down to almost as restrictive as it will go and have even tried up to 10% rice hulls. Maybe there is a recommended mill gap that is looser that .032 (aka credit card width). I've tried setting this with a credit and feeler gauge. If it's brew bag or bust I'm ok with it but wanted to see if there were any other recommendations.

The temperature is measured near the probe on the bottom of the brewzilla with the probe of Inkbird 308, so there is no difference because of different space of unit where the temperature is measured.

It is simply 2C difference in readings.

My question is :

would be temperature reading be right if I calibrate it with 60C and 80C,

because this is the range where we need to have exactly right readings of temperature.

For me does not matter if the boiling temperature is not right, when is boiling it is boiling and I can see it, but mash temperature needs to be right.

I am not entirely convinced that the inkbird probe is reading in the same position as the inbuilt probe as the probe is mounted into the boiler base and it's very hard to do this with another external probe. With that said if you did want to calibrate closer to the 60-80C this will also make the reading in this range more accurate.

In addition to this I should also add that if you really want the best temp control you really need two temp probes as the bottom temp probe near the bottom of the boiler will "never" give you the temperature of the core mash temp which is actually what you really want to achieve. So if you want to get core mash temps I highly recommend getting the bluetooth probe like this. If you use the bluetooth probe it will allow you to go higher in temperature at the boiler base where the inbuilt probe is placed so that you more quickly achieve the target temperature in the malt pipe.

Don't get me wrong, you still require a probe in the base as well to ensure the base doesn't get too hot and denature your enzymes but this is controlled via a threshold setting that you can easily setup.

Thanks, found it. Woodn’t it be easyer if you could see it in the info page?

If you are using a mobile device and use the info page it becomes very cluttered as you do not have the horizontal real estate to put that information on the side.

morpheusda

Member

Yes I am planing to buy this probe as soon as it will be available in euro web shops.I am not entirely convinced that the inkbird probe is reading in the same position as the inbuilt probe as the probe is mounted into the boiler base and it's very hard to do this with another external probe. With that said if you did want to calibrate closer to the 60-80C this will also make the reading in this range more accurate.

In addition to this I should also add that if you really want the best temp control you really need two temp probes as the bottom temp probe near the bottom of the boiler will "never" give you the temperature of the core mash temp which is actually what you really want to achieve. So if you want to get core mash temps I highly recommend getting the bluetooth probe like this. If you use the bluetooth probe it will allow you to go higher in temperature at the boiler base where the inbuilt probe is placed so that you more quickly achieve the target temperature in the malt pipe.

Don't get me wrong, you still require a probe in the base as well to ensure the base doesn't get too hot and denature your enzymes but this is controlled via a threshold setting that you can easily setup.

JoepH

Active Member

I am interested in the temp number of the rapt bluetooth thermometer on my phone not in the compleet graph.

rtstrider

Well-Known Member

- Joined

- Dec 12, 2016

- Messages

- 1,310

- Reaction score

- 847

Honestly I think I'm going to just continue with the brew bag. At the end of the day it really only adds maybe 2-3 minutes of cleaning time onto a brew day and just flat out works. Just glad the option is available!Have you considered doing no-sparge? I found that helped me tremendously (similar mill gap).

dmsn7d

Member

- Joined

- Apr 24, 2020

- Messages

- 5

- Reaction score

- 1

I just finished up my third brew 5 gal batch with the 65L 220V Brewzilla and everything went well except I am still having trouble with overshooting mash temps. I'm mashing in and letting the mash settle for 10 min before turning the pump on with the ball valve throttling the flow quite a bit. I've watched the Kegland and David Heath videos about setting up the PID. I've dropped the P value to 0.310 and it will still go 3 degrees C over my set temp. I know that the probe is at the bottom by the heating elements so the core temp of the mash is probably a degree or so lower than the stated value. I guess I'll probably just try dialing back the wattage to the heating elements. I plan to get the bluetooth thermometer and probably the heat exchangeer dish when they're available in the US. Anyone have any other tips to avoid overshooting?

Bottoms_Up

Well-Known Member

I have the 35 liter Gen 4 system, but have similar issues. I think a lot of these issues will be mostly resolved when the bluetooth thermometer and the diverter plate that fits under the bottom screen become available in North America (Canada as well as the US). I just can't understand why it takes three-quarters to a full year to get these devices here! Sure you can order direct from Kegland, but the shipping fees are just too much.I just finished up my third brew 5 gal batch with the 65L 220V Brewzilla and everything went well except I am still having trouble with overshooting mash temps. I'm mashing in and letting the mash settle for 10 min before turning the pump on with the ball valve throttling the flow quite a bit. I've watched the Kegland and David Heath videos about setting up the PID. I've dropped the P value to 0.310 and it will still go 3 degrees C over my set temp. I know that the probe is at the bottom by the heating elements so the core temp of the mash is probably a degree or so lower than the stated value. I guess I'll probably just try dialing back the wattage to the heating elements. I plan to get the bluetooth thermometer and probably the heat exchangeer dish when they're available in the US. Anyone have any other tips to avoid overshooting?

In the meantime, I try to keep the recirculation flow low (about 30-40%) so that the wort is more likely to get somewhat heated before it recirculates. I also use an inexpensive Inkbird probe thermometer with a long metallic lead that fits into the mash, to measure the mash temperature. It's a LOT of continual adjustment over the course of the mash (an hour to an hour and a half), so one needs to constantly babysit and can't just set the temperature and walk away.

I think that a LOT of people that have the Brewzilla do not measure the mash temperature and have no idea that they are mashing at the wrong temperature. The temperature, as shown on the Brewzilla, is almost always NOT the temperature of the mash, and can be as much as 5 or 6 degrees F off, or even more. I guess with IPA's it doesn't really matter too much, as the powerful grapefruit-tasting hops are so strong that they generally cover any mistakes.

But if you are attempting to make the far more subtle lagers (as I mostly do), the proper mash temperature is a VERY, VERY significant issue. The proper mash temperature is absolutely critical in this case. Lagers have far less tolerance than do ales,and especially IPA's.

So if you have a Brewzilla and are only making ales, relax, have a brew and don't worry.

But if you are making lagers/pilsners, you better start to worry and drink a LOT of brews!

I'm not bullshi*ing. I've been brewing lagers for almost 33 years!

Last edited:

Like Bottoms_Up and dmsn7d I too am suffering large overshoots in mashing temps, up to 4.9C while recirculating. I am also experiencing pump blockages more often than not. I will be using a brew bag in future to prevent the blockages. I have used a small dinner plate in the bottom of the malt pipe to attempt to push the wort to the outer edge and improve circulation past the element and temp probe as it seems the HED will do (not available in UK yet).

I'm not happy about effectively being an unpaid beta tester and being expected to pay for additional equipment to address deficiencies that should have been dealt with in product development. The G4 represents a substantial investment, perhaps naively I didn't expect these basic shortcomings to be present in the production mode. The option to monitor and control remotely is of no value at all when I feel I have to stand next to it throughout to manually compensate for its shortcomings.

I'm not happy about effectively being an unpaid beta tester and being expected to pay for additional equipment to address deficiencies that should have been dealt with in product development. The G4 represents a substantial investment, perhaps naively I didn't expect these basic shortcomings to be present in the production mode. The option to monitor and control remotely is of no value at all when I feel I have to stand next to it throughout to manually compensate for its shortcomings.

For you guys experiencing overshoots, have you dropped the hysteresis down to 0.5 or less? This is the dead zone in the temp control algorithm, where the algorithm takes this value +/- on the setpoint and thinks "temp good, do nothing". The default value is 3, which is crazy, even in an on-off control scheme. With it set there, you will see the temp oscillate +/-3 or more around the setpoint in the graph. makes precise mash control impossible.

Normally I would put this at 0 with a PID, but I haven't pulled a data sheet on the heating relay they used, so I have no idea of the lifetime cycles it is rated for. Putting between 0.2 and 0.5 cuts down on relay cycles a bunch, without really killing the temp accuracy.

My first couple brews my upper third grain temp was pretty close to the setpoint, and I hit my numbers spot on. Then I realized the temp showed low when it was just sitting at room temp, as well as mash in, so I did a calibration. It fixed the room temp and mash in temps, but my actual grain temp during the mash was suddenly very low. Ended up making a thin-bodied 7.5% red ale before I realized I was mashing at 146 instead of 154. I think the factory temp calibration builds in an offset so actual temp in the mash is close-ish to correct. I just wish this would have been communicated so we could work around it vs having to figure it out the hard way.

I also want to point out the bottom probe seems to pickup a lot of extra thermal mass from the surrounding base metal. Instead of measuring the wort temp right away, it seems to react much more slowly as the whole base warms up. Proper thermal isolation would let it actually measure wort temp in real time, and let the control algorithm actually work, as opposed to acting just as a thermal safety, which is pretty much all it is doing right now.

Normally I would put this at 0 with a PID, but I haven't pulled a data sheet on the heating relay they used, so I have no idea of the lifetime cycles it is rated for. Putting between 0.2 and 0.5 cuts down on relay cycles a bunch, without really killing the temp accuracy.

My first couple brews my upper third grain temp was pretty close to the setpoint, and I hit my numbers spot on. Then I realized the temp showed low when it was just sitting at room temp, as well as mash in, so I did a calibration. It fixed the room temp and mash in temps, but my actual grain temp during the mash was suddenly very low. Ended up making a thin-bodied 7.5% red ale before I realized I was mashing at 146 instead of 154. I think the factory temp calibration builds in an offset so actual temp in the mash is close-ish to correct. I just wish this would have been communicated so we could work around it vs having to figure it out the hard way.

I also want to point out the bottom probe seems to pickup a lot of extra thermal mass from the surrounding base metal. Instead of measuring the wort temp right away, it seems to react much more slowly as the whole base warms up. Proper thermal isolation would let it actually measure wort temp in real time, and let the control algorithm actually work, as opposed to acting just as a thermal safety, which is pretty much all it is doing right now.

Similar threads

- Replies

- 6

- Views

- 431

- Replies

- 46

- Views

- 13K

- Replies

- 46

- Views

- 16K