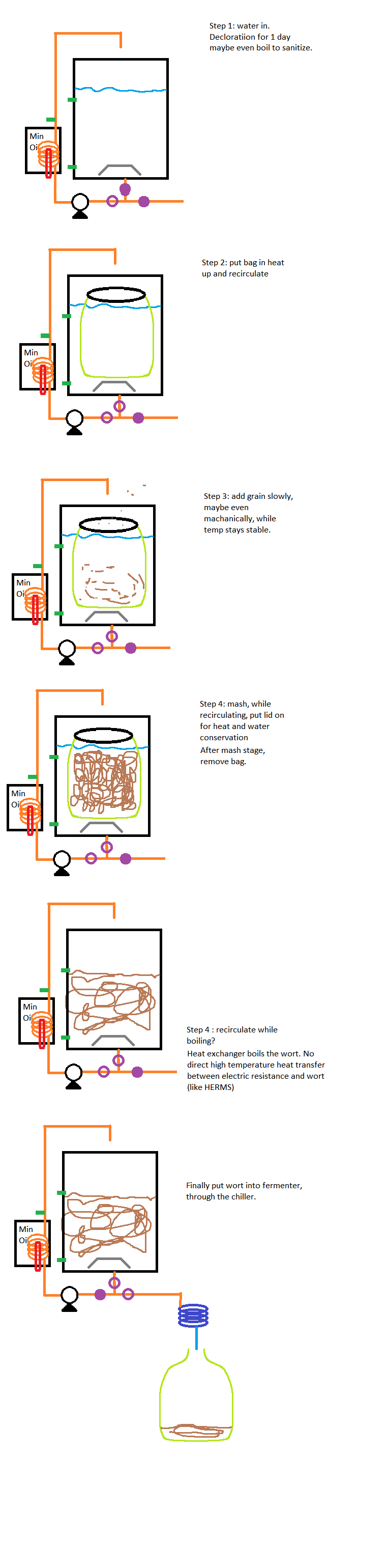

So, my name is Gonzalo, I´m an engineer, from Argentina and I´ve been looking at HERMS, BIAB and RIMS brew systems, and I´ve been thinking if I could merge part of each one fo them and create a perhaps better solution than a RIMS.

So basically I want to create a hybrid between them.

I´ll show you next in the scheme below. If I got everything right I´d be able to do everything in a single vessel.

PLEASE HIGHLIGHT any mistakes I might have over the proces and stages.

I´m new at this, but eager to improve.

Making it short. Single vessel as BIAB. Heat exchanger as in HERMS.

Special difference is that everything is done in the same vessel. Boiling occurs through the heat exchanger.

Heat exchanger is now to be calculated. Gotta grab my books again to calculate the coil length.

My idea is to have three temp sensors (open ardbird can do it?), specially one after the heat exchanger stage. Heat exchanger will use a low volume of mineral oil.

What do you think guys? I think it might work.

PS: I WANT TO USE OPEN ARDBIR FOR THIS. I have no programming skills though.

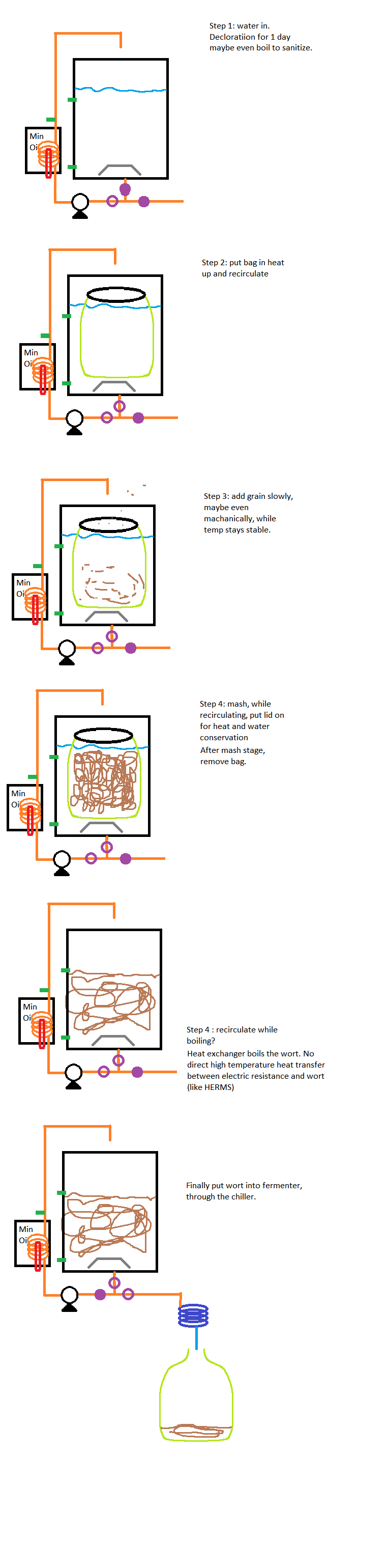

So basically I want to create a hybrid between them.

I´ll show you next in the scheme below. If I got everything right I´d be able to do everything in a single vessel.

PLEASE HIGHLIGHT any mistakes I might have over the proces and stages.

I´m new at this, but eager to improve.

Making it short. Single vessel as BIAB. Heat exchanger as in HERMS.

Special difference is that everything is done in the same vessel. Boiling occurs through the heat exchanger.

Heat exchanger is now to be calculated. Gotta grab my books again to calculate the coil length.

My idea is to have three temp sensors (open ardbird can do it?), specially one after the heat exchanger stage. Heat exchanger will use a low volume of mineral oil.

What do you think guys? I think it might work.

PS: I WANT TO USE OPEN ARDBIR FOR THIS. I have no programming skills though.