I expect it can cause a nozzle sized for higher pressure to become less than effective, hence the recommendation to use the tighter nozzles if reduced flow is desired...

Cheers!

Cheers!

That would be against everything I believe in.Great thread. Has anyone used this setup to lower the alcohol content?

I don't understand the question. Why would the way you deal with steam have anything to do with the ABV?Great thread. Has anyone used this setup to lower the alcohol content?

Pardon me asking, but why is bad to have an unknown pressure drop? The hose is certainly fine seeing an increase in pressure.

I'm not sure if this has been asked already (since we're at 23 pages so far and I don't have time to read them all at the moment), but why can't we achieve the same thing with a large coil of copper tubing, like an old immersion chiller, which is sitting on top of a box fan or some other air powered cooling source?

He means that there's not a good way to predict how much the pressure of the water coming out of the spray nozzle will be reduced when you restrict the flow. So you might not get enough atomized water to make the thing work, and even if you get it to work once, it might not be dialed in the next time.

Would this work on -or- does anyone use this on a stovetop setup?

There's no reason why it wouldn't work on a stovetop. I use an electric element inside the kettle, no difference if the heat is supplied inside the kettle or at the bottom.

Adjust your boil intensity to approximately HALF of what you're used to using and plan for about half as much boil off. For a typical example, we used to run our 5500 watt element at 65% when the kettle is full of 7 gallons and the lid off. We experienced 1.5 gallons per hour of boil off. With the Steam Slayer installed, we run at 32% and experience .75 gallons of boil off per hour. In other words, to use the Steam Slayer, your electric kettle must be equipped with a power controller.

What this means is, while boiling with a lid on, your thermal efficiency is going to be approximately doubled. You'll be able to cut your heat input in half, whatever the source of heat. The heat is carried off mostly by the rising steam, so less heat loss equals less water loss as well. The principle is the same, however the heat is produced. A stove top should work just fine.Thanks. Maybe I'm misunderstanding what's being said at this link, "your electric kettle must be equipped with a power controller" but on a stove you can also adjust the heat:

https://www.brewhardware.com/product_p/steamslayer.htm

Under Instructions in #6:

Thanks. Maybe I'm misunderstanding what's being said at this link, "your electric kettle must be equipped with a power controller" but on a stove you can also adjust the heat:

https://www.brewhardware.com/product_p/steamslayer.htm

Under Instructions in #6:

I used the steam condenser for a second time today. Love it!

But I did want to mention something. Someone a few dozen pages ago said something about the smell being even stronger and less pleasant after going to the steam condenser. Didn't really seem right.

What I did notice today, especially after running a quick errand and coming back home is that the wort smell in my house was stronger than it used to be before the steam condenser. Add to that, I could smell the canned corn smell in my house.

So before the steam condenser I used to open my garage and the side door to my garage and I'd get a good cross breeze that kept the steam down without a vent hood.

Now I keep my garage completely closed, except that I go in and out a lot and I usually let the door going from the garage to my house stay open a crack (it's a metal door that has spring hinges that make it close but if I close it softly it doesn't latch and stays open a crack).

So I don't think I'm producing more smell, I'm just not giving any of the malt smell anywhere to go besides inside my house. And the condensed liquid absolutely does have that canned corn smell to it, which isn't as nice as a clean wort smell, for sure. So I think something like that must have been going on with the other guy.

Even though I really like not having to open my garage, I might do it just to get a little airflow to carry the smell away.I've noticed the same issue with smell. It's more pungent, less...hoppy somehow. Don't know why, that water is going down the drain. My wife likes it evendors less than before.

I most cases the lid is curved, and that is where the tilt is originating. There is however significant torque due to the cantilever nature of the beast....

I noticed in a few of the photos the top mounted TC ones with a 90 degree elbow seem to be leaning an awful lot. Where's it torquing? Connection at the lid, whole lid tilting slightly to one side from non-centred placement, optical illusion?

Thanks. Maybe I'm misunderstanding what's being said at this link, "your electric kettle must be equipped with a power controller" but on a stove you can also adjust the heat:

https://www.brewhardware.com/product_p/steamslayer.htm

Under Instructions in #6:

Mine has the tilted appearance, account of the domed lid shape. I mounted it as near center as possible, to counteract any tendency to lift the lid. It turned out to be remarkably stable, in fact.Love the idea. I'm getting something like this eventually.

Apartment brewer. -30 or -40 winters. Balcony isn't fun at that point in time, not is having the door cracked to get power there. I thought about the idea a while ago. Never came to fruition with a product even worth prototyping. Ranging from crazy coils going all over the pace (too small diameter), car intercooler bolted somewhere (somewhere...) but nothing that would be of any practical use.

I noticed in a few of the photos the top mounted TC ones with a 90 degree elbow seem to be leaning an awful lot. Where's it torquing? Connection at the lid, whole lid tilting slightly to one side from non-centred placement, optical illusion?

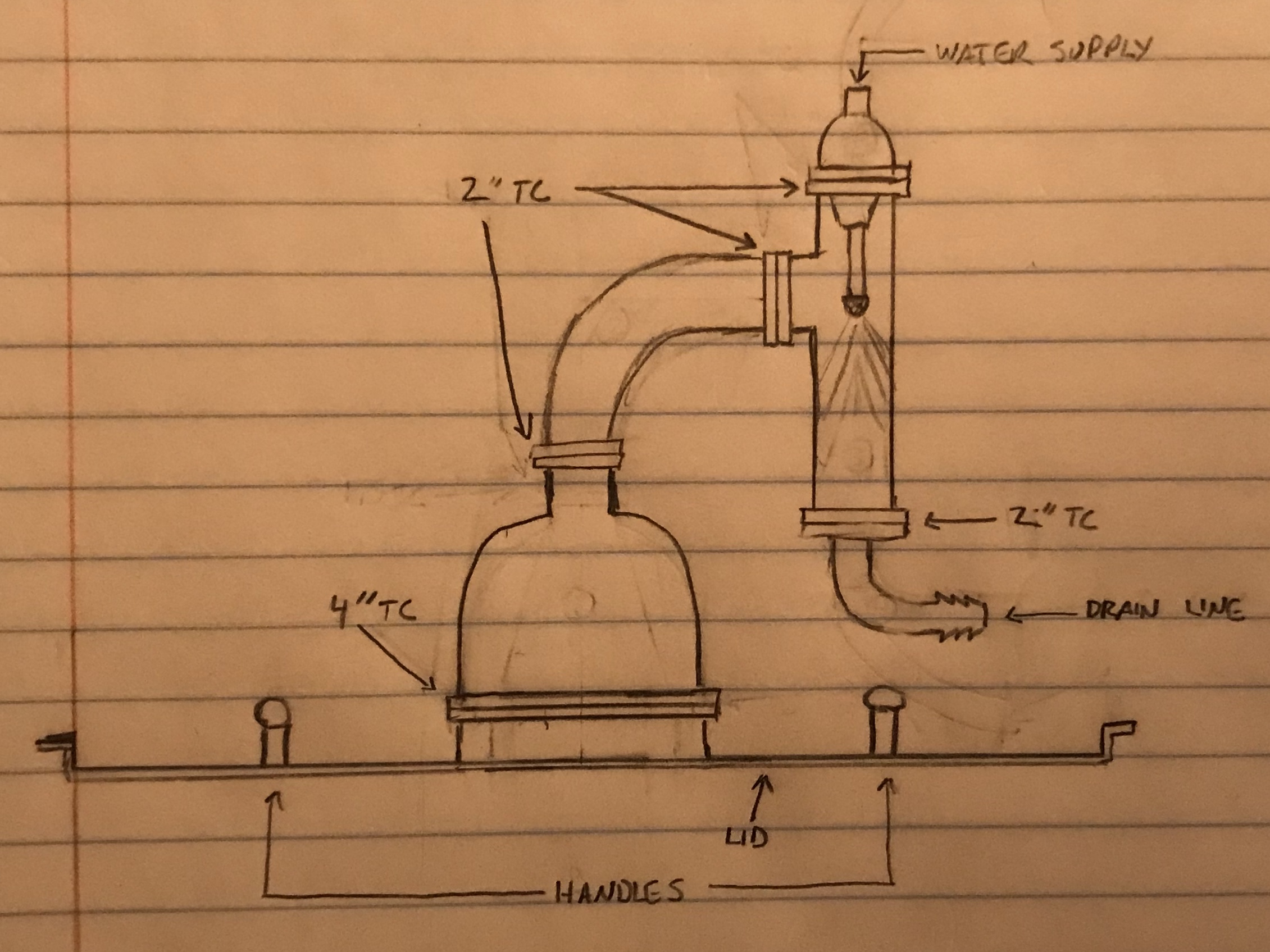

There exists a domed lid design that is also useful for other applications. You might consider a dual purpose approach when you design the steam lid.So the HVAC guy just left after quoting me for the ducting for my plans for a stainless exhaust hood which is already $$$ by itself and I was less than impressed with the estimate. I am now leaning toward a steam condenser myself. I have sorted through many of the pages of this thread and am looking where to source the spray nozzle assembly from. I would intend to use all 2" TC connections minus the reducer from the kettle. I have sketched up a design using a modified Spike Brewing kettle lid incorporating a center exhaust and two handles. For the domed reducer I sketched, I intend to use a concentric reducer for the nozzle benefits. Let me know if any of you that use condensers see any flaws with the design. Also, is the smell so bad that brewing inside would be out of the question? View attachment 603220

I'll bet you can buy a spray nozzle from Bobby at Brewhardware.com. He doesn't list them as a part, but you can get a 6gph or a 9gph spray nozzle as part of the Steam Slayer kit.

Just out of curiousity, why not just get his Steam Slayer? It's 1.5" tubing, not 2"; any reason why you're set on 2" tubing?

I will have to send him a message. My thought was 2" would just provide more steam flow, especially with the extra elbow, I suppose that 1.5" would work as well and I haven't ruled out using the steam slayer. I had a hard time finding a 4" to 1.5" reducer that I liked but there were many options at 4" to 2". I am really just in the planning phase right now as far as a condenser goes because of the exhaust hood cost. I am also waiting to hear back on some custom work about my ideas on the lid design. A domed lid straight to a 1.5" or 2" TC would be ideal IMO.

I see; I missed the 4" opening above.

I'm using the steam slayer on a 10-gallon kettle, and the 1.5" is plenty for that, even with having two 90-degree elbows. Once they heat up with steam, the steam just goes through to the condenser.

But I can see the issue with getting a reducer from 4" to 1.5".

Can you send me a picture of that when you get a chance? Do you have it coming out of the lid? Thanks for the insights.