Nimbus3000

Well-Known Member

- Joined

- Feb 14, 2015

- Messages

- 61

- Reaction score

- 21

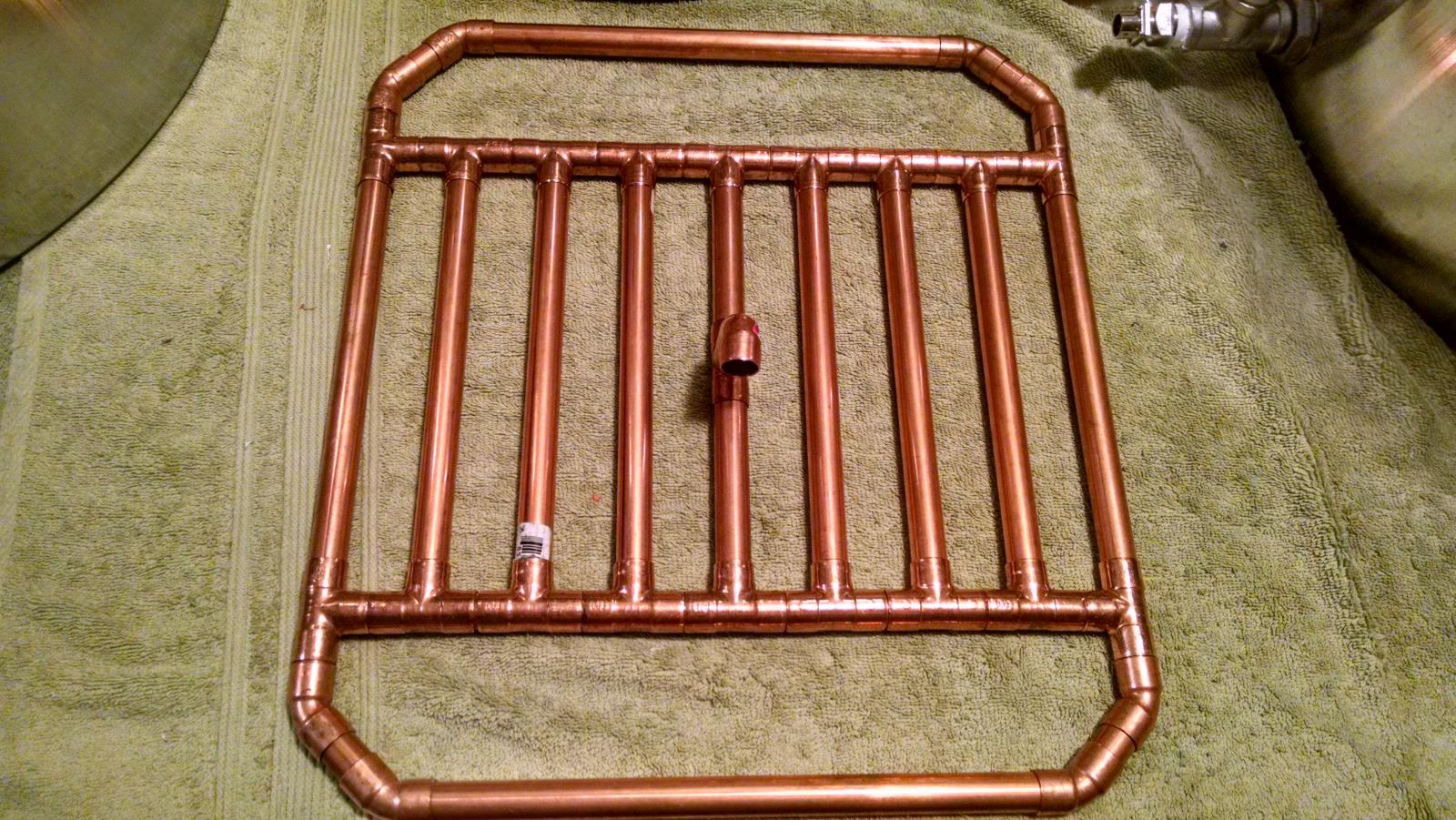

Posted a few pics into another thread so decided to compile them into a single thread. And yes I do have a Dachsund. Attached are a couple of pics of my HERMS coil that I finished today. Used 60 foot of 1/2" O.D. tubing. The support legs are aluminum since I had the material on hand (plan on replacing them with stainless later). Total height of coil is about 4 inches and 19 inches in diameter.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)