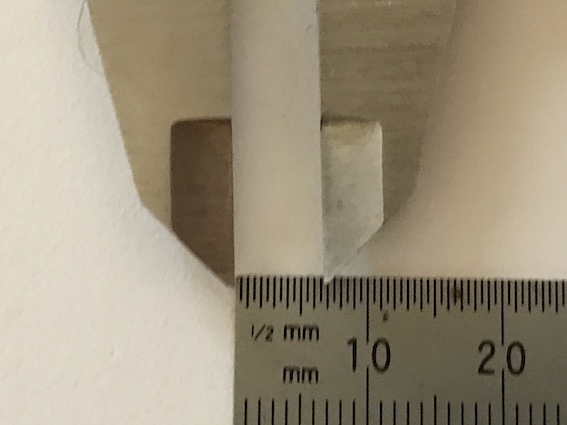

This is an idea that I have wondered about, so I am glad to see that it works for your. It seems like an easy mod for those fermenting in buckets.Being a fervent bucket fermenter, I've drilled a 1" access hole in a few bucket lids "opposite" the airlock hole,* using a 1" hole saw and then a piece of very fine sandpaper around a thick dowel to smooth the edge. They fit standard 1" bungs, creating a good seal. I can even pressurize the headspace a bit, the lid will bulge somewhat.

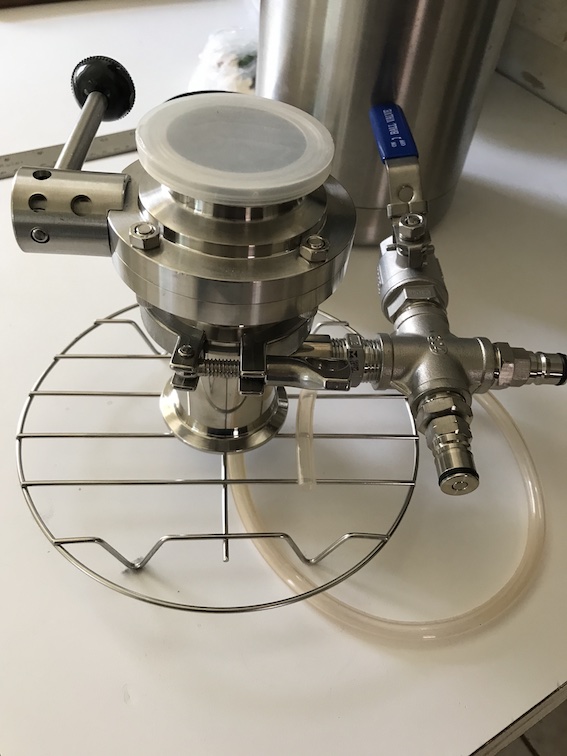

I often ferment in Fermonsters, and it is really easy to dry hop through the small opening just by removing the stopper. I also have a couple stainless bucket fermenters. I have dry hopped using a magnet approach so I don't have to open the entire lid. I have thought about adding a TC bulkhead to the top of the fermenter, just so I had a small opening where I could add dry hops.

@worlddivides : my biggest concern with adding sugar is that it will restart fermentation. You then have to add time for the yeast to consume the sugars, absorb fermentation by products, and then settle out. I would just add the hops at the tail end of fermentation to achieve the same results without extending fermentation time.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)