Cider Wraith

Well-Known Member

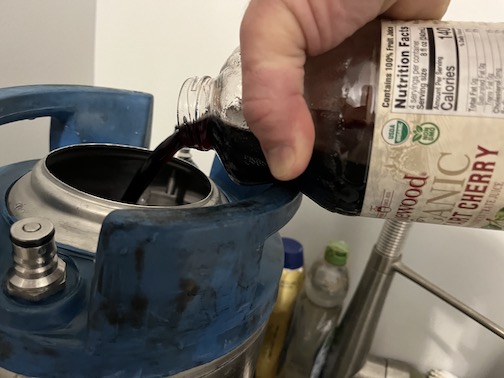

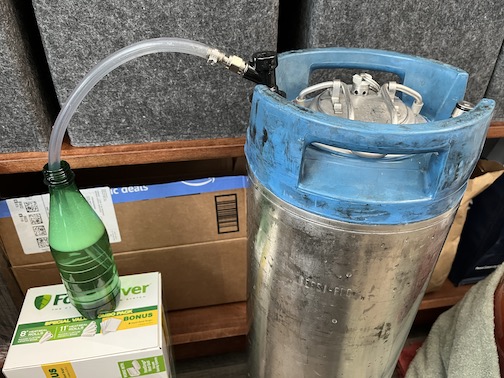

...responses to my post of a carboy at different fill levels got me reading carboy horror stories (ouch) so I'm beginning experimenting with fermenting in a Pepsi keg. For my first run I've just replaced the dip tube with a spare gas tube and I'll just do a ball connect to hose into a bottle of StarSan. (I understand I can get fancier but I'm just going to give it an initial go with two gas tubes at about 3.75 gals and I'll do a conventional auto-siphon ... later I can trim down a dip tube to get a pressurized transfer and maybe drill the lid for a stopper/air lock or whatever to get a little fancier)

...anyway, I read at what I would have guessed would have been a reliable site that "...Cornelius Kegs are listed as 5 gallon kegs but will actually hold closer to 6 gallons by volume" which didn't seem to jive with what I've experienced so I thought I'd check it out. Well, hm, doesn't look like it to me ... at least not one of my Pepsi kegs. What about yours?

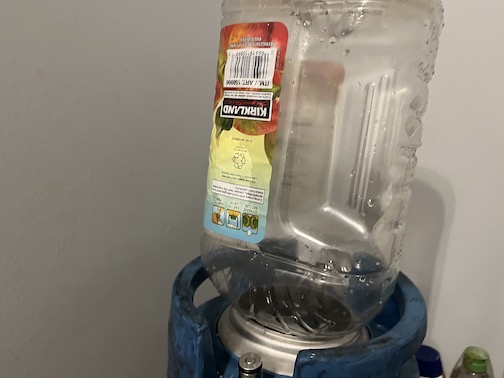

Four gallons:

Five gallons ... here touching the top of the water which is maybe a half an inch above the bottom of the gas tube:

...anyway, I read at what I would have guessed would have been a reliable site that "...Cornelius Kegs are listed as 5 gallon kegs but will actually hold closer to 6 gallons by volume" which didn't seem to jive with what I've experienced so I thought I'd check it out. Well, hm, doesn't look like it to me ... at least not one of my Pepsi kegs. What about yours?

Four gallons:

Five gallons ... here touching the top of the water which is maybe a half an inch above the bottom of the gas tube:

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)