Ok, I can brew it! The hops could still be fine tuned slightly, but I think I will declare this one cloned because I think most people wouldn't notice the difference between this one and the original.

A generic recipe is

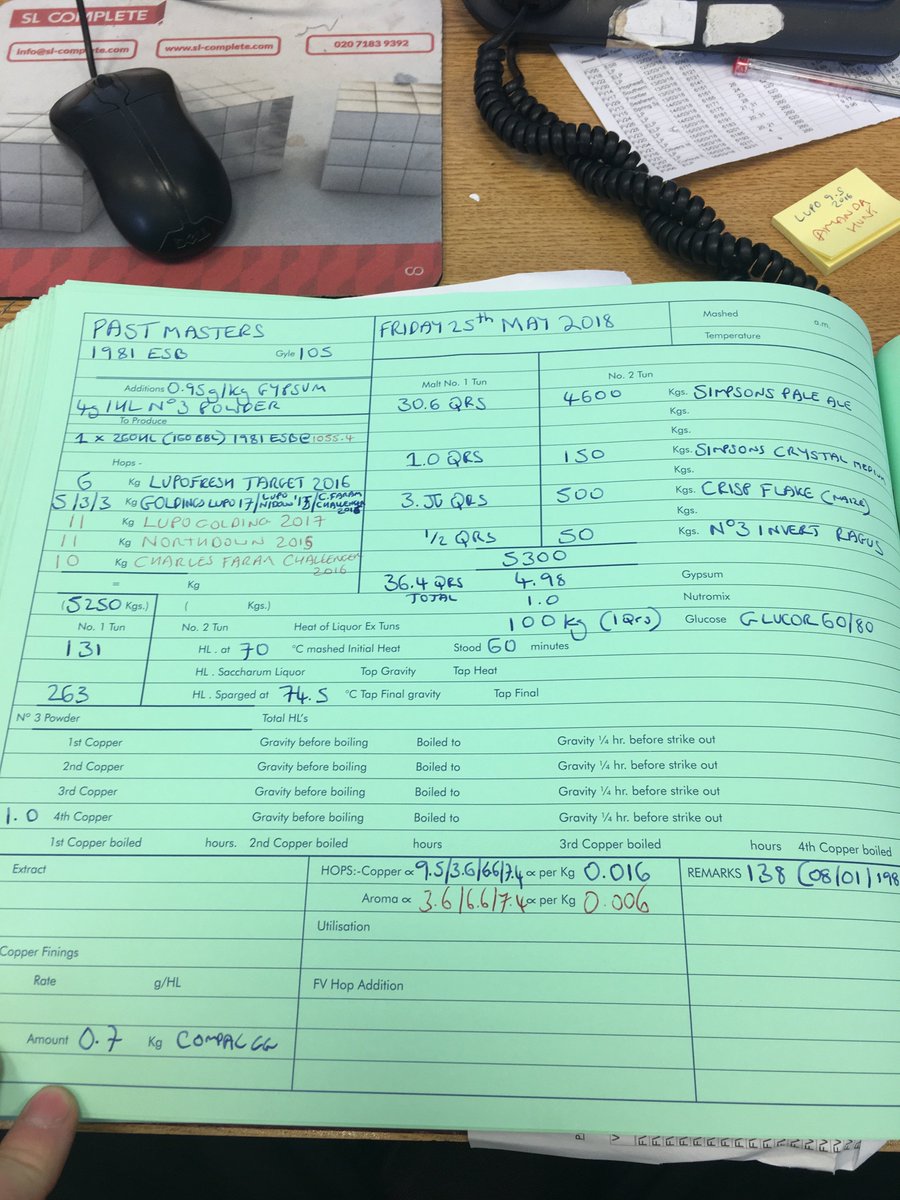

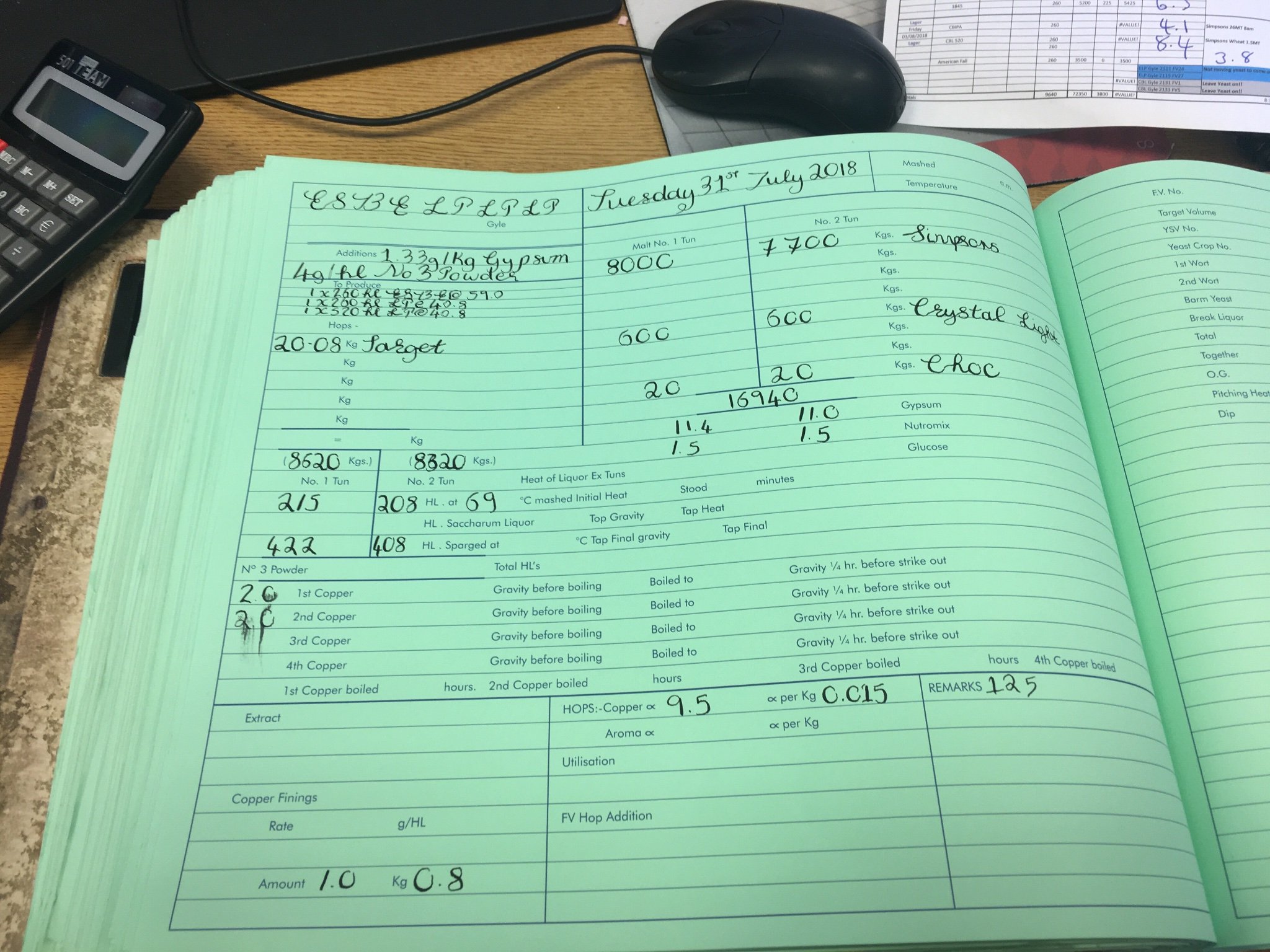

OG 1.057

FG 1.010-11

93.8% Crisp Best Ale Malt (Pale ale malt made of Flagon barley)

6% Fawcett Crystal malt (EBC150-175)

0.2% Crisp chocolate malt

1.3g gypsum per 1 kg of grain (powder added to the mash tun, leads to about max 300ppm sulphate in the wort)

base water is

this (kloridi = chloride, alkaliteetti = alkalinity, kokonaiskovuus = total hardness)

MASH & SPARGE

65°C / 90min in an infusion mash tun

drain, then sparge only once with base water (no salts) adjusted to ~pH 6 with phosphoric acid

adjust volume / pre boil gravity with base water so that post boil the wort would have OG 1.057

Boil time 60 min

HOP SCHEDULE (all hops were whole cones inside hop bags):

60 min Target so that Beersmith estimates 26.2 IBUs

2.5 min Northdown BS estimate 4.1 IBUs (=almost 3x the amount of target)

2.5 min EKG BS estimate 1.1 IBUs

2.5 min Challenger BS estimate 4.4 IBUs (=same amount as northdown)

10 min Protafloc according to instructions

Removed bittering hop bag(target) at the end of boil. Cooled in ~15 mins to room temperature (so no whirlpool/stand but the late copper hops were still there during the rapid cooling process). Continued cooling until 15 °C using copper coil. Then removed late copper hops. Let the wort stand covered in a fridge for an hour or so. Carefully transferred the clear top phase to fermenter (5 liter glass carboy, 4+ liters of wort) and added just a little bit of boiled water to get it exactly to OG 1.057 (for me post-boil it was 1.059). Let it warm up to 17-18°C in a water bath. Then pitched the yeast slurry from a 0.4 liter starter of wyeast 1968. Fermentation took place submerged in a water bath. Temperature was controlled with some ice elements. Water temperature 17-->21°C gradient, time to reach FG was approximately 4-5 days. Then 2 more days at 21°C ('diacetyl rest'). Then cooled the primary down to 0.5°C in the fridge. 2 days there. Then transferred to two secondary vessels (2 liters each) with virtually no head space and added dry hops (cones in a weighted bag). Target ~1g/liter. Also tried 2g/l but that was probably a bit too much. I kept secondaries at 20°C for 2 days, then 3+ days at 0.5°C. Then removed the hop bags and added a little bit of NBS silica gel finings adjunct and after a while 0.15g/liter of dissolved gelatin. 3+ days again at 0.5°C. Bottled in Fuller's bottles and carbonated to 2.1 vols with boiled glucose solution. 25 days in a dark place at 21°C, then chilled down to serving temperature. On the left, my bottle carbonated version, on the right Fuller's bottled, exported ESB. The Target aroma is still more pungent in Fuller's beer compared to my 1g/l and the hops may express citrus a little bit more. But they are very close now, it is not easy to distinguish these two beers.

It has been a fascinating project (my first beer as a homebrewer) and I need to thank everybody for guidance and especially the Fuller's people who have kindly revealed how they do it. I think I will brew some bottles for the summer with minor modifications in hop amounts and process. I'll now turn to Bavarian wheats and some yeast work at home, although it would be nice to brew some mild bitters, too...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)