Like McKnuckle, I'm trying to stick to Fuller's ratios on the hopping, though I'm using Challenger for bittering, and my "goldings" is First Goldings. By Promash, this, too, gives me about 25IBUs. 3 minutes before knockout with a 30 minute WP and 30 min. stand, just like McKnuckler, then IC to bring it down (so there will be additional time above 180). We'll see. I'm going to dry hop the strong bitter with a lightish touch of First Gold.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fullers recipes for ESB/Pride/Chiswick, Imperials, NEIPA - from the horse's mouth

- Thread starter Northern_Brewer

- Start date

-

- Tags

- recipes

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ESBrewer

Well-Known Member

Ok, I can brew it! The hops could still be fine tuned slightly, but I think I will declare this one cloned because I think most people wouldn't notice the difference between this one and the original.

A generic recipe is

OG 1.057

FG 1.010-11

93.8% Crisp Best Ale Malt (Pale ale malt made of Flagon barley)

6% Fawcett Crystal malt (EBC150-175)

0.2% Crisp chocolate malt

1.3g gypsum per 1 kg of grain (powder added to the mash tun, leads to about max 300ppm sulphate in the wort)

base water is this (kloridi = chloride, alkaliteetti = alkalinity, kokonaiskovuus = total hardness)

MASH & SPARGE

65°C / 90min in an infusion mash tun

drain, then sparge only once with base water (no salts) adjusted to ~pH 6 with phosphoric acid

adjust volume / pre boil gravity with base water so that post boil the wort would have OG 1.057

Boil time 60 min

HOP SCHEDULE (all hops were whole cones inside hop bags):

60 min Target so that Beersmith estimates 26.2 IBUs

2.5 min Northdown BS estimate 4.1 IBUs (=almost 3x the amount of target)

2.5 min EKG BS estimate 1.1 IBUs

2.5 min Challenger BS estimate 4.4 IBUs (=same amount as northdown)

10 min Protafloc according to instructions

Removed bittering hop bag(target) at the end of boil. Cooled in ~15 mins to room temperature (so no whirlpool/stand but the late copper hops were still there during the rapid cooling process). Continued cooling until 15 °C using copper coil. Then removed late copper hops. Let the wort stand covered in a fridge for an hour or so. Carefully transferred the clear top phase to fermenter (5 liter glass carboy, 4+ liters of wort) and added just a little bit of boiled water to get it exactly to OG 1.057 (for me post-boil it was 1.059). Let it warm up to 17-18°C in a water bath. Then pitched the yeast slurry from a 0.4 liter starter of wyeast 1968. Fermentation took place submerged in a water bath. Temperature was controlled with some ice elements. Water temperature 17-->21°C gradient, time to reach FG was approximately 4-5 days. Then 2 more days at 21°C ('diacetyl rest'). Then cooled the primary down to 0.5°C in the fridge. 2 days there. Then transferred to two secondary vessels (2 liters each) with virtually no head space and added dry hops (cones in a weighted bag). Target ~1g/liter. Also tried 2g/l but that was probably a bit too much. I kept secondaries at 20°C for 2 days, then 3+ days at 0.5°C. Then removed the hop bags and added a little bit of NBS silica gel finings adjunct and after a while 0.15g/liter of dissolved gelatin. 3+ days again at 0.5°C. Bottled in Fuller's bottles and carbonated to 2.1 vols with boiled glucose solution. 25 days in a dark place at 21°C, then chilled down to serving temperature. On the left, my bottle carbonated version, on the right Fuller's bottled, exported ESB. The Target aroma is still more pungent in Fuller's beer compared to my 1g/l and the hops may express citrus a little bit more. But they are very close now, it is not easy to distinguish these two beers.

It has been a fascinating project (my first beer as a homebrewer) and I need to thank everybody for guidance and especially the Fuller's people who have kindly revealed how they do it. I think I will brew some bottles for the summer with minor modifications in hop amounts and process. I'll now turn to Bavarian wheats and some yeast work at home, although it would be nice to brew some mild bitters, too...

A generic recipe is

OG 1.057

FG 1.010-11

93.8% Crisp Best Ale Malt (Pale ale malt made of Flagon barley)

6% Fawcett Crystal malt (EBC150-175)

0.2% Crisp chocolate malt

1.3g gypsum per 1 kg of grain (powder added to the mash tun, leads to about max 300ppm sulphate in the wort)

base water is this (kloridi = chloride, alkaliteetti = alkalinity, kokonaiskovuus = total hardness)

MASH & SPARGE

65°C / 90min in an infusion mash tun

drain, then sparge only once with base water (no salts) adjusted to ~pH 6 with phosphoric acid

adjust volume / pre boil gravity with base water so that post boil the wort would have OG 1.057

Boil time 60 min

HOP SCHEDULE (all hops were whole cones inside hop bags):

60 min Target so that Beersmith estimates 26.2 IBUs

2.5 min Northdown BS estimate 4.1 IBUs (=almost 3x the amount of target)

2.5 min EKG BS estimate 1.1 IBUs

2.5 min Challenger BS estimate 4.4 IBUs (=same amount as northdown)

10 min Protafloc according to instructions

Removed bittering hop bag(target) at the end of boil. Cooled in ~15 mins to room temperature (so no whirlpool/stand but the late copper hops were still there during the rapid cooling process). Continued cooling until 15 °C using copper coil. Then removed late copper hops. Let the wort stand covered in a fridge for an hour or so. Carefully transferred the clear top phase to fermenter (5 liter glass carboy, 4+ liters of wort) and added just a little bit of boiled water to get it exactly to OG 1.057 (for me post-boil it was 1.059). Let it warm up to 17-18°C in a water bath. Then pitched the yeast slurry from a 0.4 liter starter of wyeast 1968. Fermentation took place submerged in a water bath. Temperature was controlled with some ice elements. Water temperature 17-->21°C gradient, time to reach FG was approximately 4-5 days. Then 2 more days at 21°C ('diacetyl rest'). Then cooled the primary down to 0.5°C in the fridge. 2 days there. Then transferred to two secondary vessels (2 liters each) with virtually no head space and added dry hops (cones in a weighted bag). Target ~1g/liter. Also tried 2g/l but that was probably a bit too much. I kept secondaries at 20°C for 2 days, then 3+ days at 0.5°C. Then removed the hop bags and added a little bit of NBS silica gel finings adjunct and after a while 0.15g/liter of dissolved gelatin. 3+ days again at 0.5°C. Bottled in Fuller's bottles and carbonated to 2.1 vols with boiled glucose solution. 25 days in a dark place at 21°C, then chilled down to serving temperature. On the left, my bottle carbonated version, on the right Fuller's bottled, exported ESB. The Target aroma is still more pungent in Fuller's beer compared to my 1g/l and the hops may express citrus a little bit more. But they are very close now, it is not easy to distinguish these two beers.

It has been a fascinating project (my first beer as a homebrewer) and I need to thank everybody for guidance and especially the Fuller's people who have kindly revealed how they do it. I think I will brew some bottles for the summer with minor modifications in hop amounts and process. I'll now turn to Bavarian wheats and some yeast work at home, although it would be nice to brew some mild bitters, too...

Last edited:

thehaze

Well-Known Member

That looks very nice. Congrats!

Northern_Brewer

British - apparently some US company stole my name

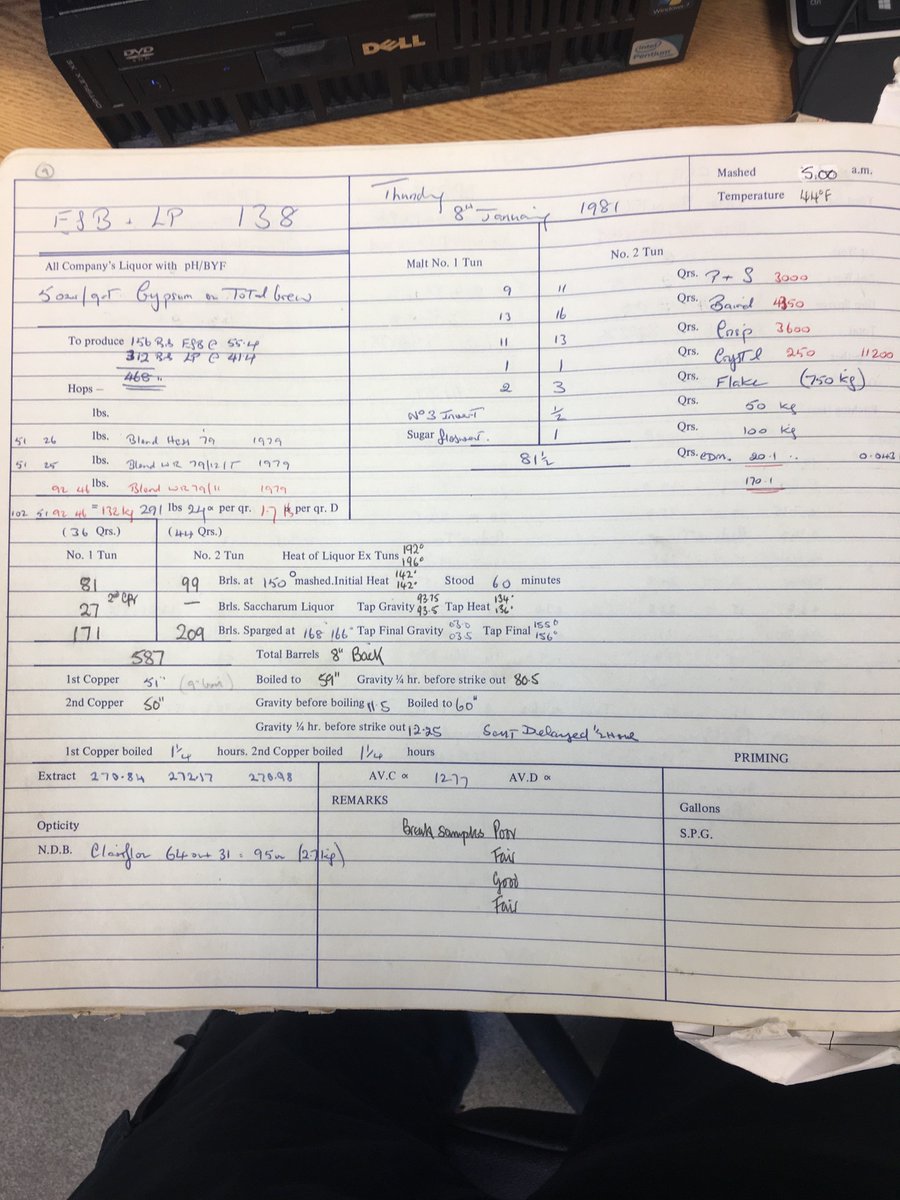

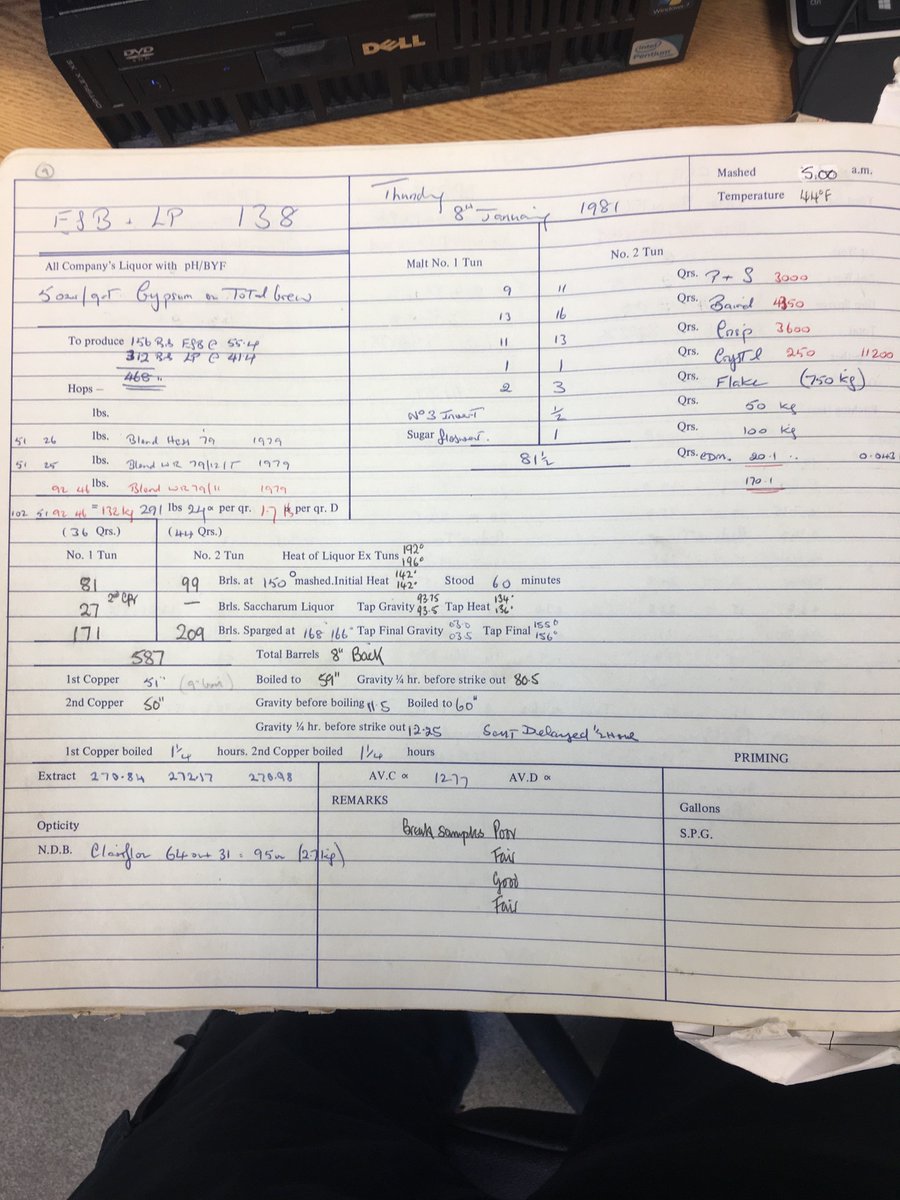

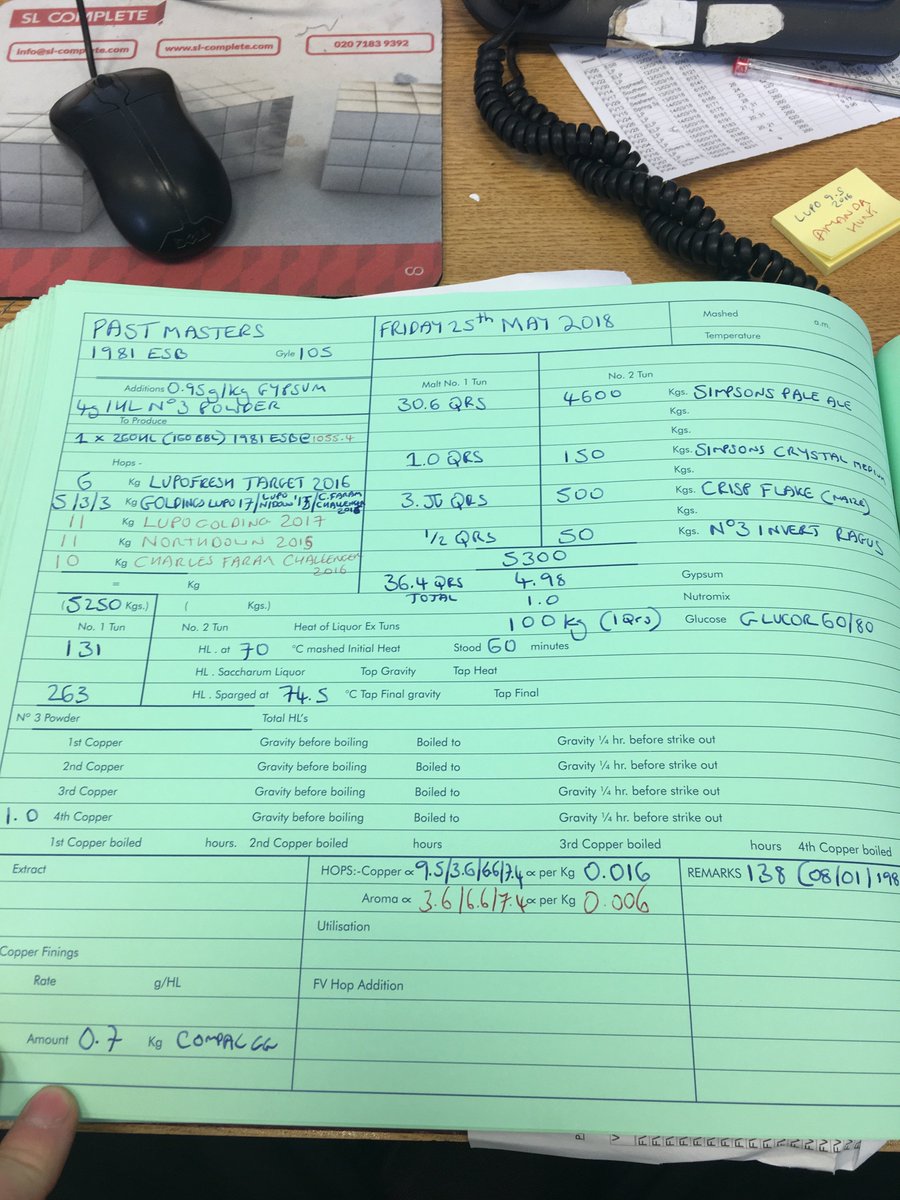

Tomorrow they're brewing a special version of ESB, recreating the first beer that John Keeling was involved with in 1981 :

https://twitter.com/FullersHenry/status/999600817639436288

Worth noting that ESB won Champion Beer of Britain a few months later (also in 1978 and 1985)

https://twitter.com/FullersHenry/status/999600817639436288

Worth noting that ESB won Champion Beer of Britain a few months later (also in 1978 and 1985)

Last edited:

ESBrewer

Well-Known Member

As I am unfamiliar with sugars in grain bill, what do you think is the main purpose of adding 50kgs (less than 1% of grain) of n°3 invert (ragus) sugar. Does this specific sugar lend some caramel taste, is it solely for color or is it purely for yeast health (providing some more rapid energy sources for yeast)? It is difficult to see that it would much affect the body and perception by thinning out the maltiness when the amount is so low. And the maize seems to be there to reduce the maltiness. And what do you think is the main reason many brewer's seem to have turned away from sugar (and maize) additions in British pale ales, but not in strong Belgian ales. These are ingredients that seem to be present in almost every recipe that dates back to 20th century. Is it more about the evolution of beer taste or is it more about a bad mental image associated with sugar in food (although yeast converts these sugars) that has led breweries, including Fuller's, to diminish sugar (and maize) in pale ales. Or is it just that they noticed the same thing (color) can be obtained with specialty grains (something that they probably knew already in the 19th century..).

Last edited:

As I am unfamiliar with sugars in grain bill, what do you think is the main purpose of adding 50kgs (less than 1% of grain) of n°3 invert (ragus) sugar. Does this specific sugar lend some caramel taste, is it solely for color or is it purely for yeast health (providing some more rapid energy sources for yeast)? It is difficult to see that it would much affect the body and perception by thinning out the maltiness when the amount is so low. And the maize seems to be there to reduce the maltiness. And what do you think is the main reason many brewer's seem to have turned away from sugar (and maize) additions in British pale ales, but not in strong Belgian ales. These are ingredients that seem to be present in almost every recipe that dates back to 20th century. Is it more about the evolution of beer taste or is it more about a bad mental image associated with sugar in food (although yeast converts these sugars) that has led breweries, including Fuller's, to diminish sugar (and maize) in pale ales. Or is it just that they noticed the same thing (color) can be obtained with specialty grains (something that they probably knew already in the 19th century..).

I just red this. It has enough information for you question.

https://byo.com/article/sweetness-brewing-sugars-how-to-use-them/

ESBrewer

Well-Known Member

Thanks, I am aware of all that general technical knowledge (what different sugars might be doing), but I still don't know what is the driving force why British brewers changed from sugar/caramel to more crystal/roasted malts after maybe 100 years of brewing mainly with some invert sugars and maize. And what has been the main purpose of the invert sugar syrup in ESB, does it differ a lot from the increased crystal malt character. Hmm..maybe I have to brew the traditional version and see how it tastes, side by side.

Last edited:

BrewnWKopperKat

ʘ‿ʘ

but I still don't know what is the driving force why British brewers changed from sugar/caramel to more crystal/roasted malts after maybe 100 years of brewing mainly with some invert sugars and maize. And what has been the main purpose of the invert sugar syrup in ESB, does it differ a lot from the increased crystal malt character.

Ron Pattinson's "Shut up about Barclay Perkins" blog (https://barclayperkins.blogspot.com/) may be what you are looking for.

Northern_Brewer

British - apparently some US company stole my name

Thanks, I am aware of all that general technical knowledge (what different sugars might be doing), but I still don't know what is the driving force why British brewers changed from sugar/caramel to more crystal/roasted malts after maybe 100 years of brewing mainly with some invert sugars and maize. And what has been the main purpose of the invert sugar syrup in ESB, does it differ a lot from the increased crystal malt character. Hmm..maybe I have to brew the traditional version and see how it tastes, side by side.

The driving force was CAMRA whose logic, ignoring 150 years of history went :

Macro beer used adjuncts.

Macro beer was Bad Beer.

Therefore adjunct beer is Bad Beer.

Therefore Good Beer cannot be made with adjuncts

So there was a lot of pressure on the "good guys" to drop the use of adjuncts, even if this version of ESB used adjuncts and was good enough to become Champion Beer of Britain. Another minor factor was joining the EU led to higher prices for Britain's traditional brewing sugar, from Caribbean cane, relative to domestic beet sugar which isn't as good for brewing.

Yes, invert #3 will add a little flavour, but don't ignore the 100kg of glucose that will "dilute" the flavour so overall I'd look at that 150kg of sugar mix as a cheap approximation to dry malt extract. It's the sort of thing commercial brewers do for consistency, to hit their OG targets. Also it allows you to "stretch" the brew a bit, either for money reasons or eg because your mash tun only holds 5.25 tonnes of grain and a poor harvest means that you need 5.4 tonnes to hit your OG target.

The main effect of that sugar is just to dry it out a little bit when you're using a low-attenuating yeast.

ESBrewer

Well-Known Member

Thanks, so using the syrup, sugar and maize could give you something that is actually quite similar to malt (in a bit more fermentable package) but these additions gave a little bit more flexibility to the process. Personally, I am not sure if I would like to dry this beer out below 1.010 so I think I'll go without adjuncts in the future, too. But it could be nice to try it with a bit darker crystal, using less crystal than the modern recipe.

Northern_Brewer

British - apparently some US company stole my name

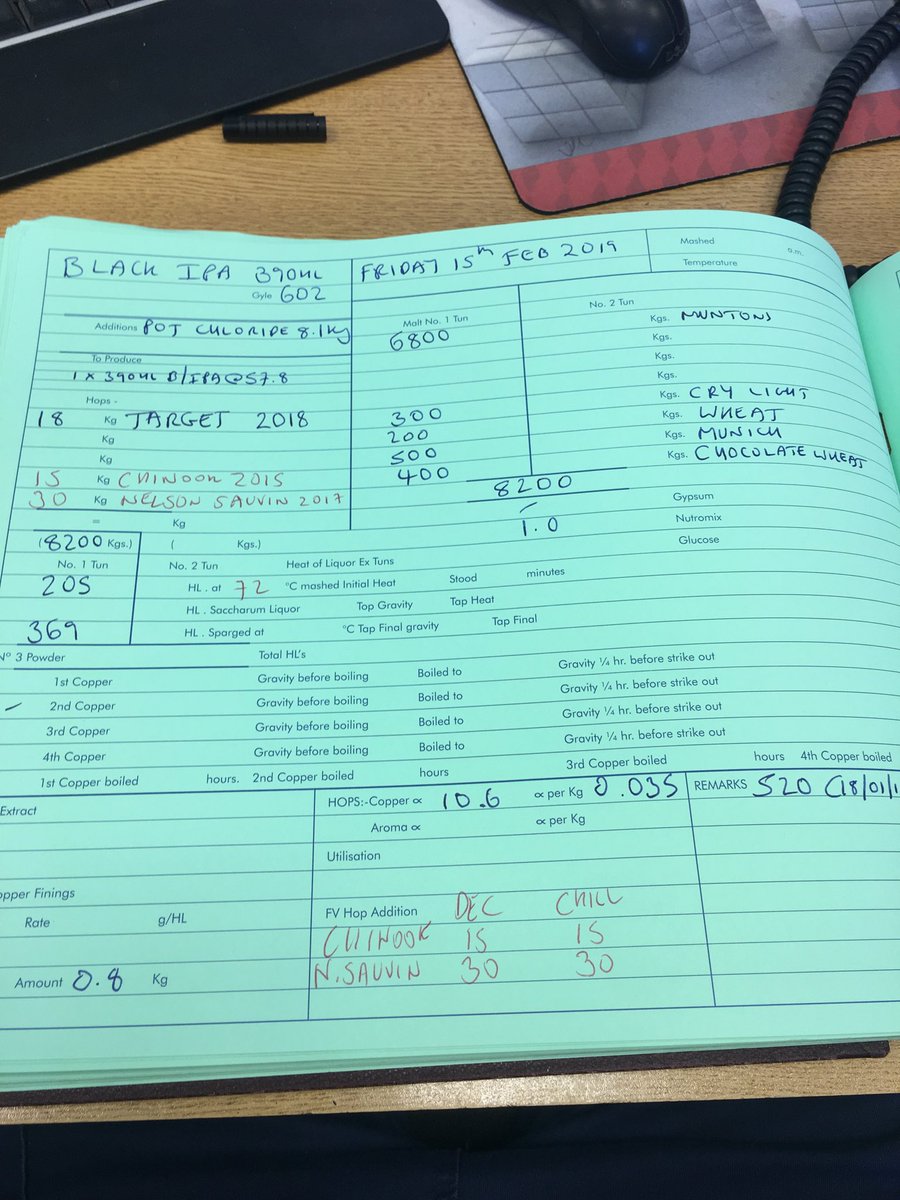

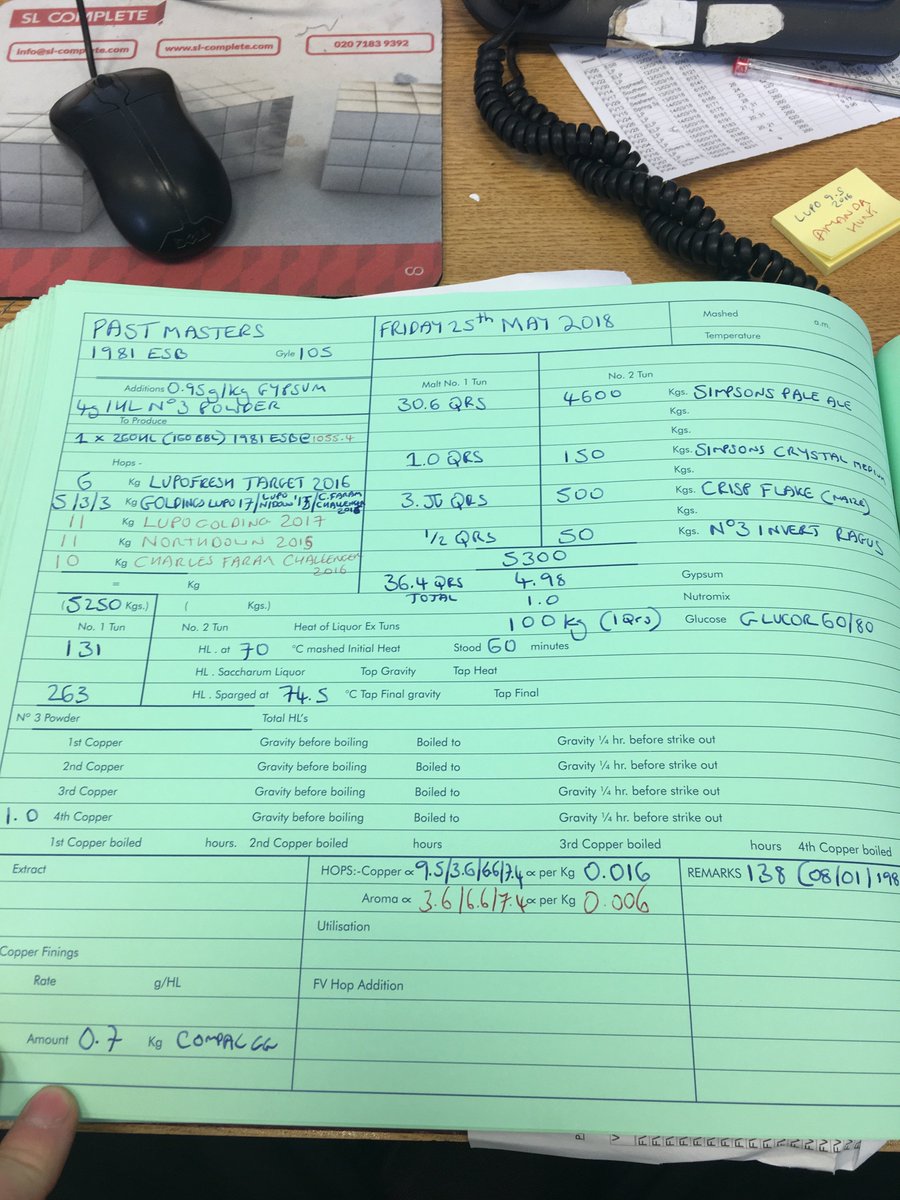

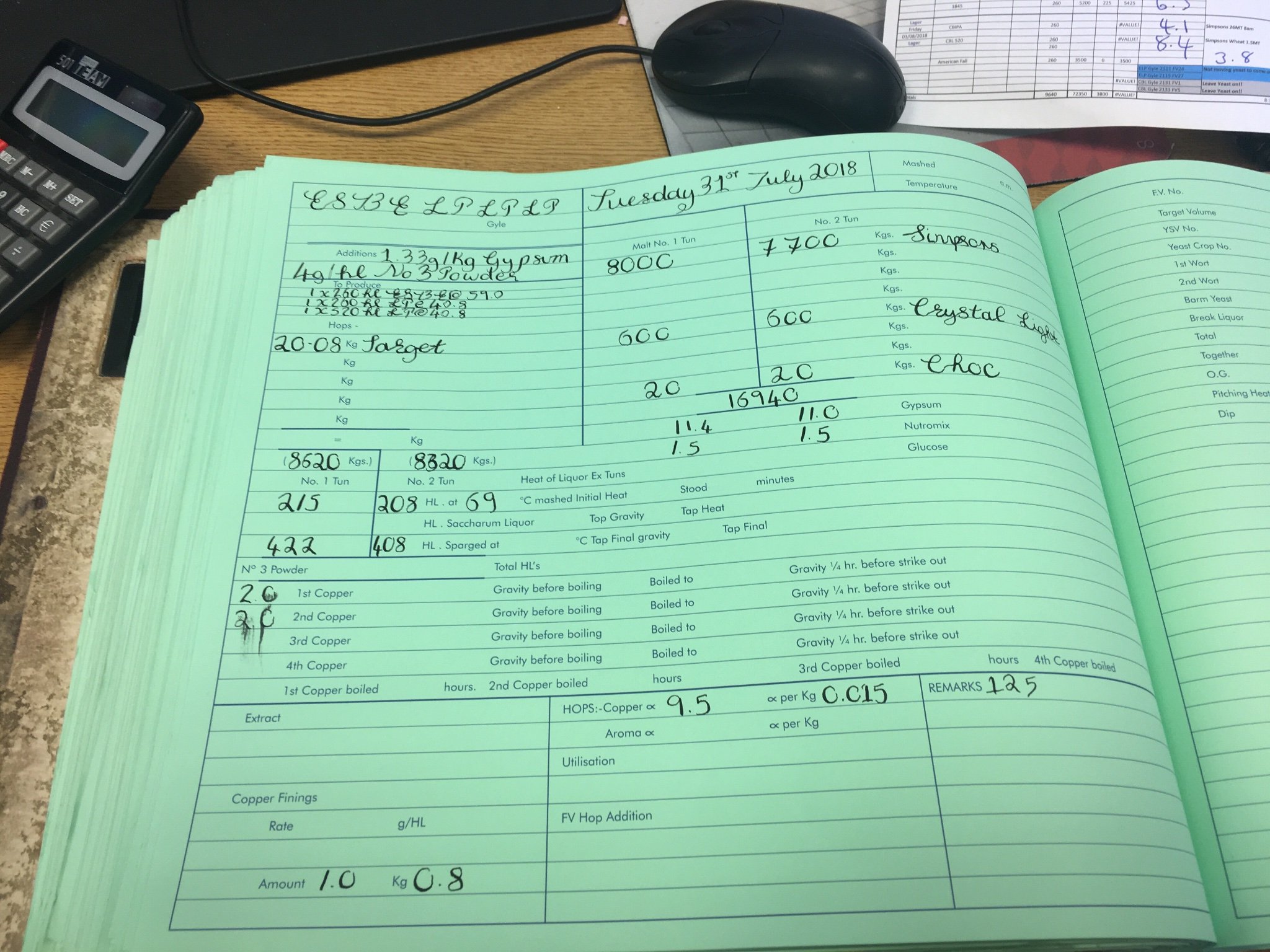

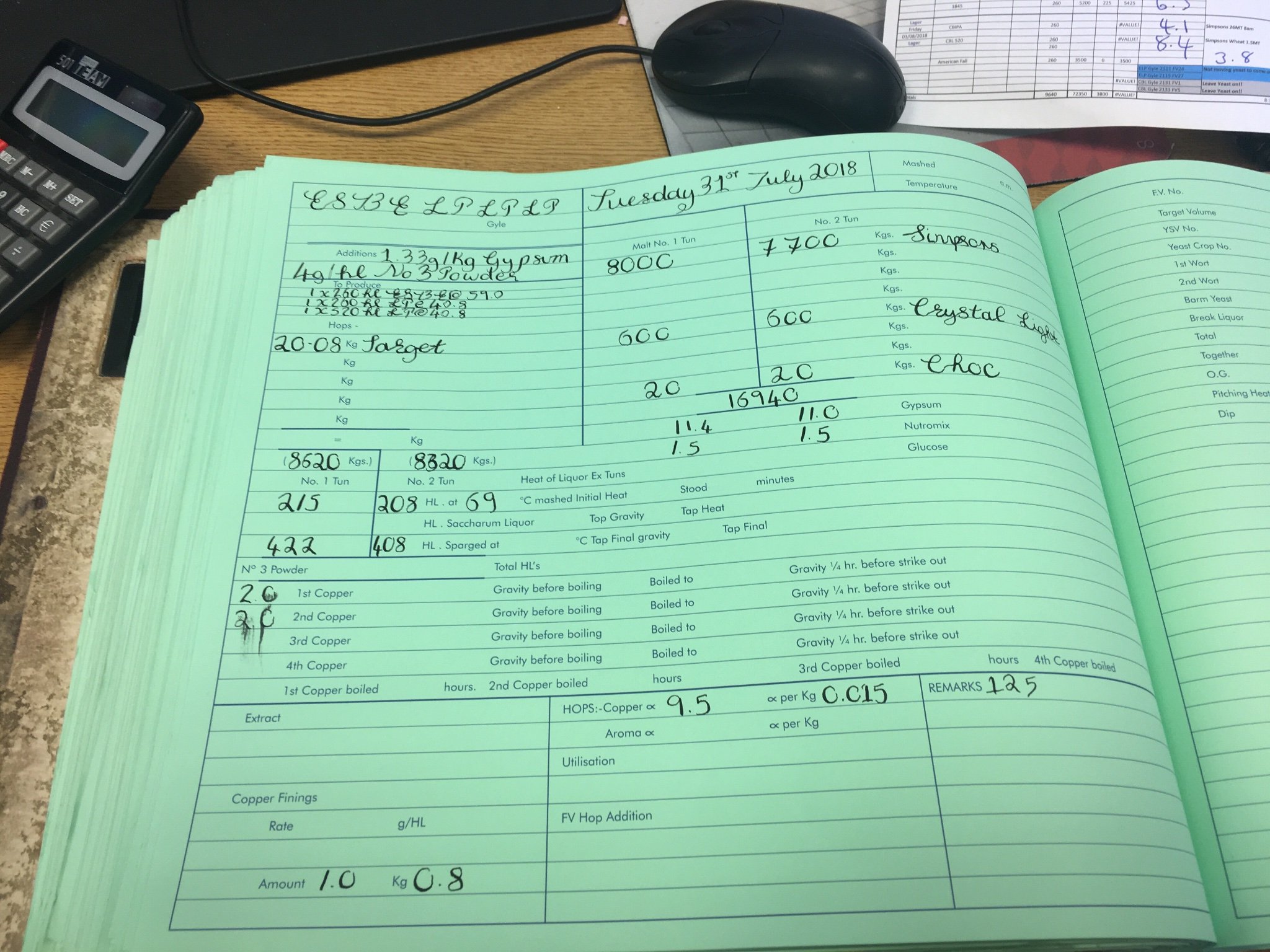

Another page from the brewbook for next Tuesday - Henry wanted to show off the fact he'd written it with a proper ink pen. Only the bittering hops are showing at the moment; given that it's an ESB +3xPride batch, it gets a tonne more grain than the one at the start of the thread which was a ESB:2 Pride:Chiswick brew. Obviously using ?2017 Target with a bit less alpha than ?previous harvest?.

ESBrewer

Well-Known Member

I just bottled an ESB that was brewed with the yeast extracted from a bottle of their 1845. There is an unusual heat wave in Northern Europe and it was too difficult to control the temperature of my water bath so I eventually gave up. I started out at 20C and after a day or so the temp went up to 24-26C for the rest of the fermentation. It has a very distinct orange marmalade character and I didn't notice the higher alcohols or ketones too much. This is exactly the taste that makes this beer so unique, when it combines with the refreshing hop bitterness. The yeast behaved much like wyeast 1968, FG, OG, other fermentation characteristics were similar. Used Fawcett's Golden Promise and that seems to work well in this type of beer, too.

Last edited:

Northern_Brewer

British - apparently some US company stole my name

I picked up a bottle of Imperial Stout today, I assume dating back to that pre-Christmas brew? Waitrose have it in a blue version of the Vintage box at £8/500ml (!) I'm in two minds whether to keep it or just drink it - not really the weather for it at the moment, but that price doesn't exactly encourage buying a couple to keep on spec....

ESBrewer

Well-Known Member

Their yeast (at least the single colony I picked) seems to form less sediment in the bottles compared to the wyeast strain, indicating that yeast from the bottle could be more flocculent. But there could be other explanations for this. Need to brew again when the weather gets cooler so that all the temps are comparable.

ESBrewer

Well-Known Member

I just tasted Fuller's 1981 Past Masters version of ESB (see the recipe above). I must say that it's very bland and thin compared to the new one, so it seems that they've made a lot of progress here. There is not much of that nice hop aroma and the body is definitely watery (thanks to the maize and dextrose), although the color is deeper compared to the modern version and head is less white (yellowish) in color. I would go with the modern version, anytime!

Last edited:

That's a shame. The version they did last year with Moor that was based on the 1971 recipe was excellent, although i think the hops were different

just reading through the thread again, i see i posted in it earlier on that that ESB "Rebirth" was good

also there are still packs of the fuller &friends multipack from last year still available in some waitroses . guess it didnt sell well

just reading through the thread again, i see i posted in it earlier on that that ESB "Rebirth" was good

also there are still packs of the fuller &friends multipack from last year still available in some waitroses . guess it didnt sell well

Northern_Brewer

British - apparently some US company stole my name

I had the 1981 version on cask against the modern one at the GBBF and I would have been quite that rude about it - yes it was thinner and a touch less flavoursome, but recognisably the same beer. I had the bottle version on its own yesterday at BrewCon with John Keeling - I waited until the crowds died down, so unfortunately the modern one had run out, again it didn't seem _so_ far from the current one, but I'll admit I'm not a regular drinker of it.

Various points that came out of yesterday :

One thing I hadn't really thought about as a reason for partigyling is that it allows much more effective management of energy suppplies, you can arrange it so that you're not boiling the whole wort at the same time.

They tend to aim slightly high for gravity, and then dilute with up to 5% water.

Declaration is the point at which they declare the specs of the wort to the tax authorities for duty.

London Pride is roughly 50:50 mix of the two mashes - about 2/3 of the malt go in the first one for 1.080, the second is 1.018 (?? didn't quite catch this).

Fuller's started sparging in the early 1900s - originally in 3 floods. They adopted continuous sparging once technology was developed.

Pride is about 2/3 their volume.

I'd not heard before that one reason for using flaked maize was to help finings to work, and he thought it "opened out" the flavour a bit.

They centrifuge out all the yeast, then add back 0.5m cells/ml for conditioning where appropriate, it is the production strain in the bottles.

They used the modern single strain (which latest research suggests is a double strain) for recreating old beers like the 1891 XX - he was a bit vague about using the original strain, I suspect it had to fit in with current production so they had to use modern yeast in the conicals.

He used to think Vintage was best at 5 years, now things it's 10.

They've been on municipal water since the 1900s, they just add gypsum and adjust pH.

Various points that came out of yesterday :

One thing I hadn't really thought about as a reason for partigyling is that it allows much more effective management of energy suppplies, you can arrange it so that you're not boiling the whole wort at the same time.

They tend to aim slightly high for gravity, and then dilute with up to 5% water.

Declaration is the point at which they declare the specs of the wort to the tax authorities for duty.

London Pride is roughly 50:50 mix of the two mashes - about 2/3 of the malt go in the first one for 1.080, the second is 1.018 (?? didn't quite catch this).

Fuller's started sparging in the early 1900s - originally in 3 floods. They adopted continuous sparging once technology was developed.

Pride is about 2/3 their volume.

I'd not heard before that one reason for using flaked maize was to help finings to work, and he thought it "opened out" the flavour a bit.

They centrifuge out all the yeast, then add back 0.5m cells/ml for conditioning where appropriate, it is the production strain in the bottles.

They used the modern single strain (which latest research suggests is a double strain) for recreating old beers like the 1891 XX - he was a bit vague about using the original strain, I suspect it had to fit in with current production so they had to use modern yeast in the conicals.

He used to think Vintage was best at 5 years, now things it's 10.

They've been on municipal water since the 1900s, they just add gypsum and adjust pH.

ESBrewer

Well-Known Member

Thanks, some great information again. I have another bottle of 1981 waiting in the fridge, need to try it some day together with the new one when the yeast has settled appropriately. It's bottle conditioned & exported.

Interesting that they use the municipal water, I know some water has great variation but i see from the water report for their area that it doesn't really vary very much, which i suppose makes more sense for a city as large as london. So with fairly low-ish levels of sulphate and chloride they really just need to get a handle on the alkalinity then add more salts if needed

http://twmediadevcdn.azureedge.net/waterquality/WQ Report_Z0347_Chiswick & Hammersmith.pdf

I have a bottle of vintage in my fridge from last year, I was going to try it against a fresh bottle from this year and keep another one for a similar tasting next year. I don't think I can really be bothered ageing them much more than that!

Incidentally , when I tasted the rebirth version of ESB at the same time as current ESB, this is what I said about it

"

in summary, the rebirth was better but they also bore similarities - typical bit of fullers marmalade, the minerally dryishness of the finish were exactly the same. rebirth had the fresher/more floral nose and taste and was slightly thinner.

"

http://twmediadevcdn.azureedge.net/waterquality/WQ Report_Z0347_Chiswick & Hammersmith.pdf

I have a bottle of vintage in my fridge from last year, I was going to try it against a fresh bottle from this year and keep another one for a similar tasting next year. I don't think I can really be bothered ageing them much more than that!

Incidentally , when I tasted the rebirth version of ESB at the same time as current ESB, this is what I said about it

"

in summary, the rebirth was better but they also bore similarities - typical bit of fullers marmalade, the minerally dryishness of the finish were exactly the same. rebirth had the fresher/more floral nose and taste and was slightly thinner.

"

ESBrewer

Well-Known Member

I'd not heard before that one reason for using flaked maize was to help finings to work, and he thought it "opened out" the flavour a bit.

I've read from some sources, that the original idea behind maize would have been to dilute not only the body (and cut costs), but also to dilute the high amount of protein in the barley, that would cause haze. So the beers with maize were considered visually more appealing (low protein wort could also mean that less finings are needed to produce clear wort). Never really heard that maize could directly affect the finings but who knows? Today, especially the top quality British/German malting barley is so low in protein that this type of protein dilution is probably useless. And the methods to fine & filter beers have probably developed from those times.

Many British ale breweries seem to be quite pedant about the procedure of dropping the yeast, often very soon post-fermentation or even few gravity points before the fermenetation has finished, indicating that the exact amount of yeast is probably important for the development of taste. I have also noticed (in my very limited nr of brews) that dropping excess yeast by not only cold crashing but using gelatin can lead to good results, although this time when brewing the ESB clone, I think I'm going to make a small test by adding some fresh yeast to some bottles at the time of bottling.They centrifuge out all the yeast, then add back 0.5m cells/ml for conditioning where appropriate, it is the production strain in the bottles.

Interesting and valuable information that it is probably not just a single strain.modern single strain (which latest research suggests is a double strain)

The municipal water is something that Keeling also mentioned in (if I remember correctly) "Can you brew it"-podcast interview and I also immediately went to check the Chiswick water profile. My water tends to be even softer and I've found that using our water, the pH of a typical ESB mash comes to ~pH5.5 by adding just 1.33g gypsum + a hint of CaCl2 /kg grain, even without further pH adjustment.

Last edited:

Northern_Brewer

British - apparently some US company stole my name

I've read from some sources, that the original idea behind maize would have been to dilute not only the body (and cut costs), but also to dilute the high amount of protein in the barley, that would cause haze. So the beers with maize were considered visually more appealing (low protein wort could also mean that less finings are needed to produce clear wort). Never really heard that maize could directly affect the finings but who knows? Today, especially the top quality British/German malting barley is so low in protein that this type of protein dilution is probably useless.

Also mentioned that. Although CAMRA focussed on adjuncts as a cost-cutting measure, when you look into it the costs don't look so different - certainly for sugars, there were good brewing reasons for doing it that way.

I think it's more that the British tend to think more about conditioning than other brewers since most of their output (traditionally at least) was in cask. You get very rapid feedback from your own tied pubs if the conditioning is "wrong"! And then that's followed through with their approach to bottling - there's a fair bit of pressure from CAMRA to at least have "premium" bottles as bottle-conditioned even though it's a complete nightmare since so much can happen once bottles leave the brewery. So you try to control as much as possible what happens in the brewery.Many British ale breweries seem to be quite pedant about the procedure of dropping the yeast, often very soon post-fermentation or even few gravity points before the fermenetation has finished, indicating that the exact amount of yeast is probably important for the development of taste.

Interesting and valuable information that it is probably not just a single strain.

Meh - I suspect it's like a lot of these yeasts, you'll get something that looks like 3 strains using standard microbiology and 10 strains with DNA analysis. Whether that makes a material difference to the beer, I wouldn't be so sure. From Fuller's point of view, the big change was in 1976 when they went to conicals and went from three ("microbiology") strains down to one.

I always read your posts when i see there is a reply to some thread I've been on add they rarely disappointAlso mentioned that. Although CAMRA focussed on adjuncts as a cost-cutting measure, when you look into it the costs don't look so different - certainly for sugars, there were good brewing reasons for doing it that way.

I think it's more that the British tend to think more about conditioning than other brewers since most of their output (traditionally at least) was in cask. You get very rapid feedback from your own tied pubs if the conditioning is "wrong"! And then that's followed through with their approach to bottling - there's a fair bit of pressure from CAMRA to at least have "premium" bottles as bottle-conditioned even though it's a complete nightmare since so much can happen once bottles leave the brewery. So you try to control as much as possible what happens in the brewery.

Meh - I suspect it's like a lot of these yeasts, you'll get something that looks like 3 strains using standard microbiology and 10 strains with DNA analysis. Whether that makes a material difference to the beer, I wouldn't be so sure. From Fuller's point of view, the big change was in 1976 when they went to conicals and went from three ("microbiology") strains down to one.

You got a book or a blog going on? Plenty of good geekery in my humble opinion.

Northern_Brewer

British - apparently some US company stole my name

I always read your posts when i see there is a reply to some thread I've been on add they rarely disappoint

You got a book or a blog going on? Plenty of good geekery in my humble opinion.

Too kind. Nope, this is all I've got...

Northern_Brewer

British - apparently some US company stole my name

yesterday at BrewCon with John Keeling

There's a pretty low quality recording of his talk here - unfortunately the slides are barely visible but there wasn't that much on them.

Although i do take umbrage with you claiming Northern.. being a Scottish Finn, to me youre a southern nancyToo kind. Nope, this is all I've got...

Northern_Brewer

British - apparently some US company stole my name

Hey, if we're going on blood then I'm mostly Scottish, including a good chunk from the Black Isle - so not that southern.... I'll give you Finland though!

ESBrewer

Well-Known Member

Now waiting for some Eskimos to join the conversation while sipping Rebirth. It's decent. I like it more than 1981. Rebirth is slightly more hop driven but the current production version is the best. It is the most balanced version (IMO).

Derp

Well-Known Member

Just read that Fuller’s have sold their brewing business to Japan’s Asahi. Sad day...

Silver_Is_Money

Larry Sayre, Developer of 'Mash Made Easy'

Just read that Fuller’s have sold their brewing business to Japan’s Asahi. Sad day...

Indeed true, and indeed sad. Asahi also owns Pilsner Urquell. 2 of my 3 favorite beers are now owned by Asahi.

https://www.msn.com/en-gb/finance/o...er-business-to-asahi-for-c2-a3250m/ar-BBSIuD1

Northern_Brewer

British - apparently some US company stole my name

Makes sense for both parties - 23.6xEBITDA is a rich price that is hard to turn down, but they're good brands that work internationally and fit nicely with the second-best London lager brand, Meantime, that Asahi picked up as part of the fallout from the ABI/SAB merger. And it's part of a general trend with UK brewers disposing of their beer brands to concentrate on pubs serving a bigger choice of brands than the tie would allow.

- Joined

- Aug 8, 2017

- Messages

- 1,507

- Reaction score

- 1,761

Ok, I can brew it! The hops could still be fine tuned slightly, but I think I will declare this one cloned because I think most people wouldn't notice the difference between this one and the original.

A generic recipe is

OG 1.057

FG 1.010-11

93.8% Crisp Best Ale Malt (Pale ale malt made of Flagon barley)

6% Fawcett Crystal malt (EBC150-175)

0.2% Crisp chocolate malt

1.3g gypsum per 1 kg of grain (powder added to the mash tun, leads to about max 300ppm sulphate in the wort)

base water is this (kloridi = chloride, alkaliteetti = alkalinity, kokonaiskovuus = total hardness)

MASH & SPARGE

65°C / 90min in an infusion mash tun

drain, then sparge only once with base water (no salts) adjusted to ~pH 6 with phosphoric acid

adjust volume / pre boil gravity with base water so that post boil the wort would have OG 1.057

Boil time 60 min

HOP SCHEDULE (all hops were whole cones inside hop bags):

60 min Target so that Beersmith estimates 26.2 IBUs

2.5 min Northdown BS estimate 4.1 IBUs (=almost 3x the amount of target)

2.5 min EKG BS estimate 1.1 IBUs

2.5 min Challenger BS estimate 4.4 IBUs (=same amount as northdown)

10 min Protafloc according to instructions

Removed bittering hop bag(target) at the end of boil. Cooled in ~15 mins to room temperature (so no whirlpool/stand but the late copper hops were still there during the rapid cooling process). Continued cooling until 15 °C using copper coil. Then removed late copper hops. Let the wort stand covered in a fridge for an hour or so. Carefully transferred the clear top phase to fermenter (5 liter glass carboy, 4+ liters of wort) and added just a little bit of boiled water to get it exactly to OG 1.057 (for me post-boil it was 1.059). Let it warm up to 17-18°C in a water bath. Then pitched the yeast slurry from a 0.4 liter starter of wyeast 1968. Fermentation took place submerged in a water bath. Temperature was controlled with some ice elements. Water temperature 17-->21°C gradient, time to reach FG was approximately 4-5 days. Then 2 more days at 21°C ('diacetyl rest'). Then cooled the primary down to 0.5°C in the fridge. 2 days there. Then transferred to two secondary vessels (2 liters each) with virtually no head space and added dry hops (cones in a weighted bag). Target ~1g/liter. Also tried 2g/l but that was probably a bit too much. I kept secondaries at 20°C for 2 days, then 3+ days at 0.5°C. Then removed the hop bags and added a little bit of NBS silica gel finings adjunct and after a while 0.15g/liter of dissolved gelatin. 3+ days again at 0.5°C. Bottled in Fuller's bottles and carbonated to 2.1 vols with boiled glucose solution. 25 days in a dark place at 21°C, then chilled down to serving temperature. On the left, my bottle carbonated version, on the right Fuller's bottled, exported ESB. The Target aroma is still more pungent in Fuller's beer compared to my 1g/l and the hops may express citrus a little bit more. But they are very close now, it is not easy to distinguish these two beers.

View attachment 567285

It has been a fascinating project (my first beer as a homebrewer) and I need to thank everybody for guidance and especially the Fuller's people who have kindly revealed how they do it. I think I will brew some bottles for the summer with minor modifications in hop amounts and process. I'll now turn to Bavarian wheats and some yeast work at home, although it would be nice to brew some mild bitters, too...

ESBbrewer you should start your own Fullers ESB Clone thread! This much time and effort deserves much attention!!! Thank you for sharing!!!

Northern_Brewer

British - apparently some US company stole my name

couchsending

Well-Known Member

- Joined

- Jun 21, 2016

- Messages

- 3,032

- Reaction score

- 2,131

The potassium chloride addition is interesting. Even with my horrible math that seems like a lot. Anyone care to scale that down? I don’t know their recipes or system to know water volumes.

ESBrewer

Well-Known Member

Batch volume seems to be 39000 liters so 8.1 kgs(?) probably means about 0.2 grams KCl per one liter of beer. A moderate addition to add a bit of chloride. KCl is probably anhydrous so they add 95 mg chloride per liter of beer. Base water is probably London (Chiswick) municipal water. That would mean 140-150mg/liter chloride altogether if we assume all the chloride ends up in the beer. But I wonder why they prefer potassium over calcium here ?

Last edited:

couchsending

Well-Known Member

- Joined

- Jun 21, 2016

- Messages

- 3,032

- Reaction score

- 2,131

Batch volume seems to be 39000 liters so 8.1 kgs(?) probably means about 0.2 grams KCl per one liter of beer. A moderate addition to add a bit of chloride. KCl is probably anhydrous so they add 95 mg chloride per liter of beer. Base water is probably London (Chiswick) municipal water. That would mean 140-150mg/liter chloride altogether if we assume all the chloride ends up in the beer. But I wonder why they prefer potassium over calcium here ?

Based on that water report Ca is somewhere between 90 and 110 right?

Lots of hops and high Cl combined with Ca over 100 can get rather chalky/mineraly/bitter. They probably want to keep the Ca down and up the Cl.

Interesting that it’s twice as much KCL as their stout recipe that’s listed in this thread.

ESBrewer

Well-Known Member

Yes could be, and of course calcium would bring the pH further down unlike potassium. So they already have enough calcium and no need to bring it further down.

Last edited: