kal

Well-Known Member

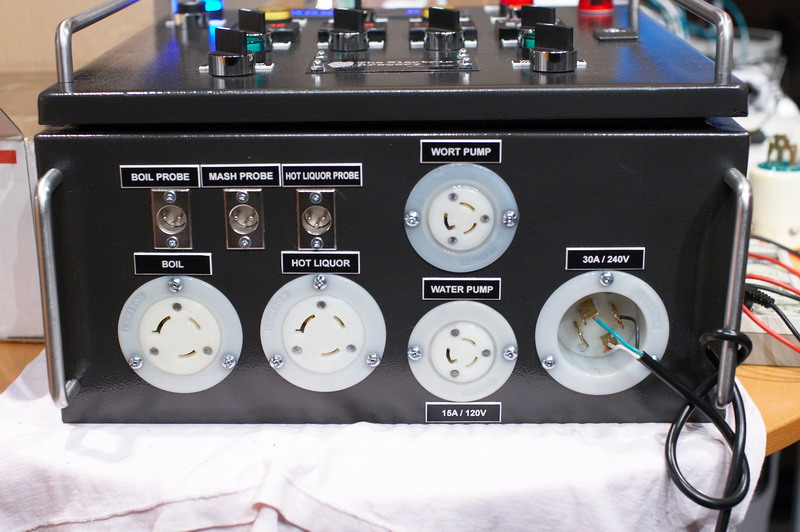

I'm thinking of doing the following:

*Regular* 30A 2-pole breaker in the panel -> 10/4 wire -> some sort of 'disconnect switch' to power the brew panel on/off -> 30A dryer outlet.

The brew panel will be plugged into the dryer outlet using this 30A/240V 2-pole 4-wire GFI cord to provide protection:

$80 off ebay: 30A Ground Fault Interrupt Plug GFI CordCable FREE SHIP - eBay (item 110302613578 end time Jan-19-09 10:23:22 PST)

It's pretty inexpensive. Anyone ever use one of these? They don't mention if it's a "Class A" GFI. That's about my only concern.

One of the nice things about putting the GFI in the cable is that I can then take my brew setup with me elsewhere as we have 'brew day' events around here. 30A dryer outlets are easy to find.

Kal

Got this 30A GFI cable today. The thing is *MASSIVE*. I had concerns about the build quality as it was hard to tell from the pictures but the cord shielding is super-thick and the actual GFI module is almost a FOOT long. It's huge the whole thing weighs almost 8 lbs.

Kal

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)