Gregredic

Well-Known Member

This cord is great. It will save me from having to buy a 30A breaker that is GFCI.

Safer than what? Using a GFI in a cord like I showed above? If yes, why?The GFCI breakers are expensivebut it is safer so I'm going that route...

Helping a lot actually. It's always good to constantly re-think things and you guys are keeping me thinking!Hope we are helping a bit Kal... opinions are like a$$holes, we all have them, but yours is the one that you should worry about

There's that disconnect thing again...FWIW, I used 50A GFCI -> 6/3 wire -> range outlet -> range cord -> disconnect -> Subpanel w/ 2 30A and 1 15A circuits

There's that disconnect thing again...Anyone have a picture/link to what it is? Google doesn't help as it's a pretty generic term. What exactly is a "disconnect"?

Safer than what? Using a GFI in a cord like I showed above? If yes, why?

Kal

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I am enjoying the discussion. I am also building an electric rig. What I am planning, FWIW, is 50A GFCI -> 6/3 + ground wire -> Subpanel w/ 1 30A breaker -> 10/4 stranded wire to a 4 prong 30 amp dryer outlet -> 10/4 wire to the control panel -> 10/4 wire to the 5500 watt element. The subpanel has slots for future expansion if I want to run a 120v curcuit. I may also add outlets to the control panel to run 2 elements but not at the same time.

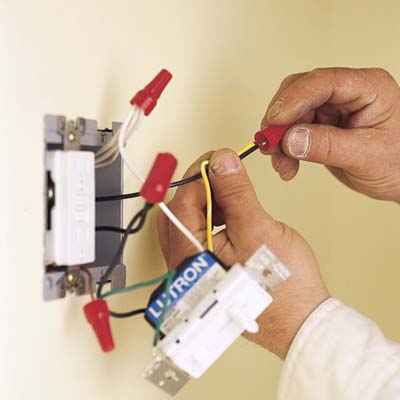

Got it! Thank you! So just a big switch essentially. Can you use these to power on/off the brew panel so that no 30A+ power switch is required in the brew panel? Assuming it won't be turned on/off more than say once a day (more likely once a month).Here's what mine looks like:

I already have 25' of 10/4 so I will use half to go from the wall to the control panel and the other half from the control panel to the burner. If I didn't already have the 10/4, I agree, 10/3 is what I should use.I'm no electrican but that setup makes sense to me. The only typo I see is that the wire to the elements is 10/3 not 10/4 (there's no need for a neutral). You can use 10/4 wire if you want, just cap the neutral with a marret.

I'd go even further and ask what the consensus is on large wire nuts vs distribution blocks?

I didn't want to use 6 gauge wire everywhere the 220 went. I may not have had to but the sub panel wasn't that expensive and I already had a regular 30 amp breaker for the sub panel. I can also add a 120 v breaker to the subpanel and it will be protected by the gfci as well.

Every person that keeps saying that I am no electrician should not be giving advise when they have no idea what is available or needed (to code).

but it would basically be considered an appliance..... i will submit a brew rig diagram and i bet i can get it passed.

For the record: there is basically no way to build an electric brew rig to code. We are building (or have built) hot water heaters. However, it's not very hard to wire from main box to the receptacle to code - a basic wiring book has that in it, as well as subpanels, etc. You can actually read the real codes as well (I did for parts of it.) Actually on the brew rig, we can give advice on what has work and should work based on other electrical wiring principles and how other "to code" wiring implementations might be done. In the end, it's just unprofessional advice

That's the disclaimer. Electricity can kill you. Never ever do anything that's not to code. My posts should never be followed and are for reference only.

If you need to hire an electrical contractor or engineer to tell you not build an electric brew rig (because, legally, that's what they should do), then please do. However, if you have issues running a basic 30A circuit, you can hire that out, but I'd recommend you seriously reconsider going electric. If you have trouble with a pretty simple 240V circuit, then you probably don't need to screw around with SSR's and 5400W heater elements.

There, does that make you happy?

Why is it such a bad thing to have one leg still hot to the element?

All I was trying to say here is get someone with electronic experience to help with the engineering of the circuits if you have very little ability with electronics.

I went on a semi-rant about this in another thread:

https://www.homebrewtalk.com/f11/bl...rms-conversion-93217/index14.html#post1036288

Basically, use a DPST switch on the element circuit and turn it off when you want element to be completely off.