I see that, but I just don't understand it. Maybe I'm being too obtuse.

I just don't understand why having a RIMS or HERMS system gives you any greater control over mash temp than having a recirculating one pot system. I also don't understand why you would go with a RIMS or HERMS system to try and get better efficiency. In part, the extra half a pound of grain at bulk prices runs another $0.75 to get the same final gravity. If your HERMS or RIMS system costs $800 (and I know it doesn't) it would take 1,000 brews to justify the cost difference over just getting some more grain. And even at that point, you could just crush a little finer with BIAB to get the same final gravity.

It's a very common system, I get it. I see them for sale second hand all the time, and see companies offering the three vessel system for big cash. I just don't understand it. A commercial brewery can't put their grain in a bag, and can't afford to throw an extra hundred pounds of grain in a mash tun. Which is why they need a three vessel (or two) system. But on a 5 gallon or 10 gallon system I just don't see it as worthwhile.

But who knows. Maybe my attitude will change over time.

That's exactly what I was going for. Thank you for the validation.

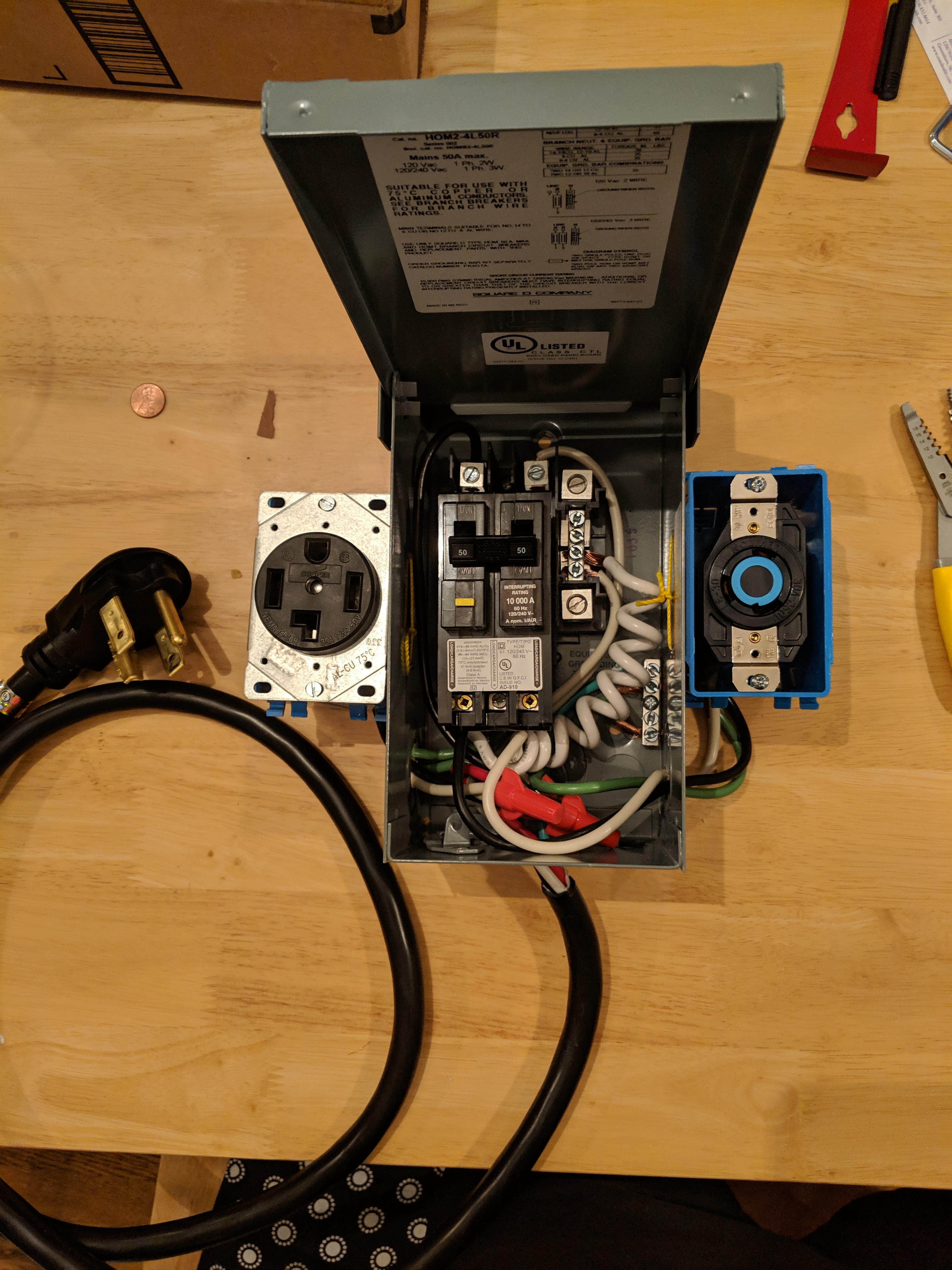

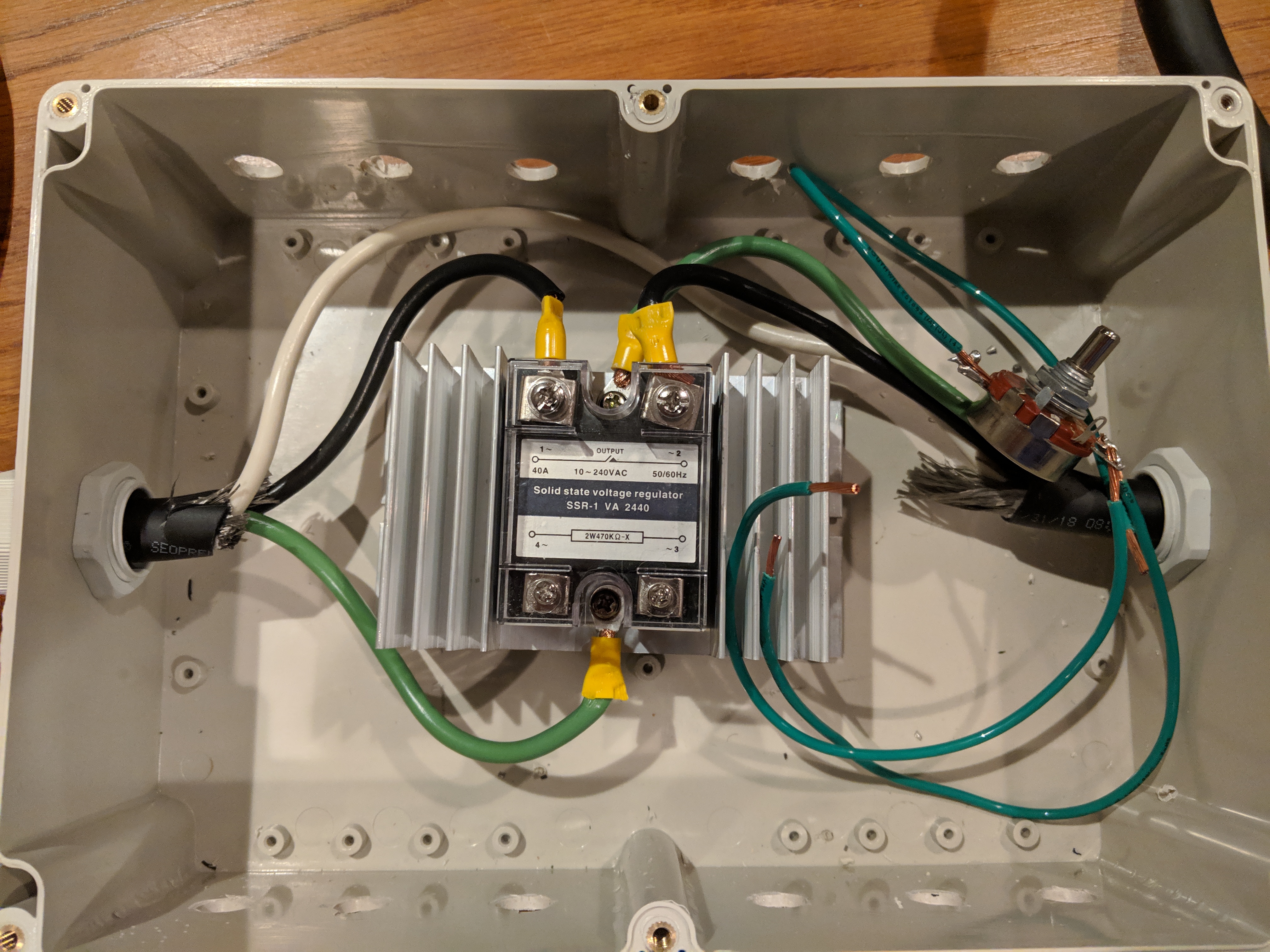

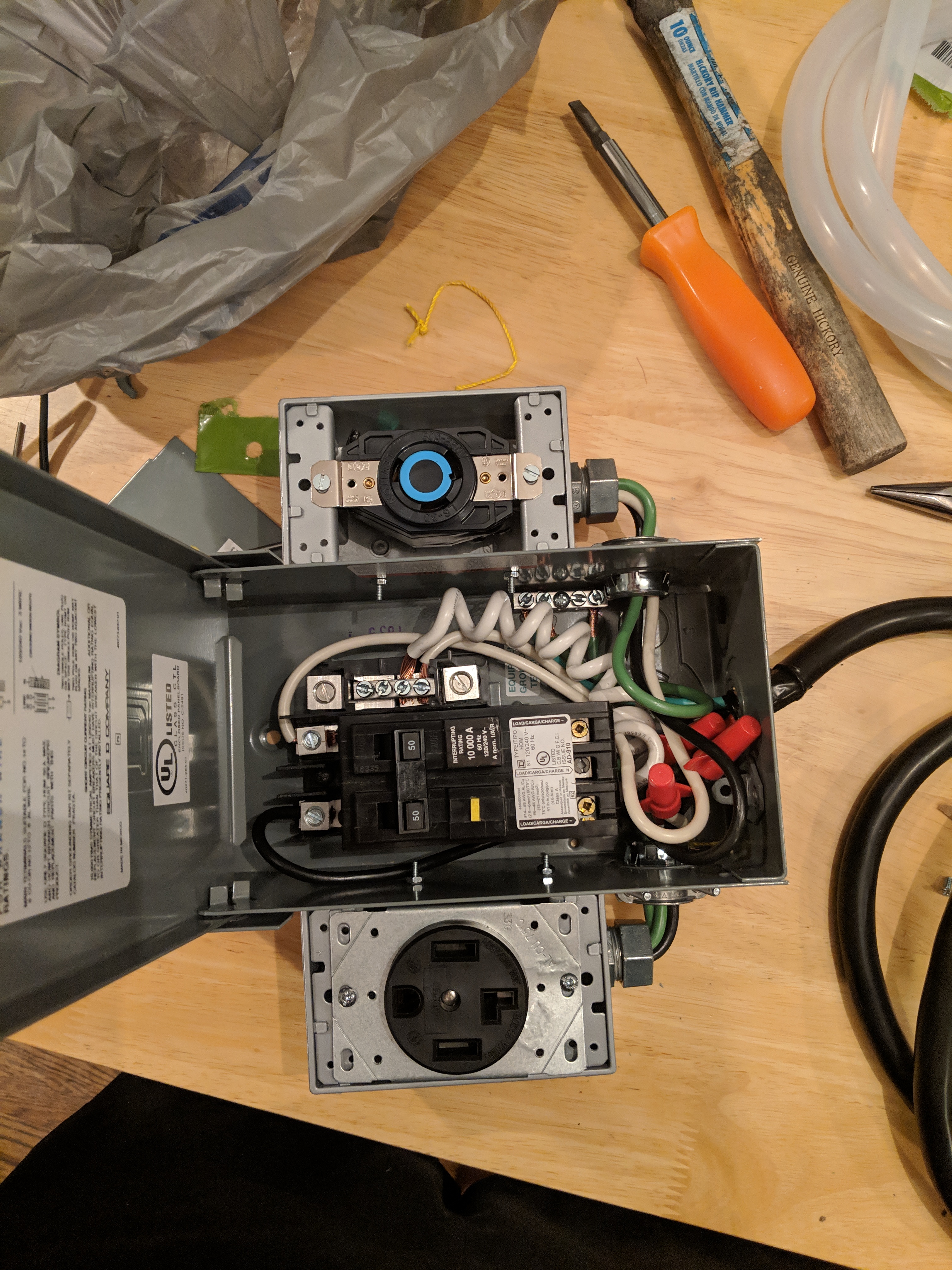

Honestly I started on this journey looking for a bigger kettle. My 7.5 gallon pot wasn't going to work forever. If I was getting a bigger kettle, I mine as well get an output valve on it. And if I'm getting an output valve on it, I mine as well get all the ports I could imagine using later on. It was only at that point that I figured "why would I get a kettle that has a port for an electric heater, but not get the electric heater?"

The rest of the ports I currently have no plans on using. I also have no plans on making a 10 gallon batch. But I can if I want to in a year, or 5. I can add a mash re-circulation, or a steamslayer, or a whirlpool pump, or a PID controller, or ditch the BIAB and go with a 3 vessel system. Hopefully not (for my wallets sake), but you never know