I'm looking to wire a 110V 15a eBIAB CraftBeerPi setup. I've read the GitHub documentation for installing CBP on the Pi, but had a couple of wiring questions:

1.) After reading through the monster CraftBeerPi HBT thread and watching a couple of YouTube videos, a couple folks suggested using a ULN2803A Darlington Array, to ensure that the Pi can trigger the element SSR and is less likely to be fried if something dumb happens. However, I didn't see much in the way of instructions (for the wiring inexperienced) about a permanemt setup using a ULN2803a without a breadboard or a CBP PCB. Would one of these boards work for the pictured wiring diagram? (Amazon.com: Voltage Driver Power Supply Module, 2Pcs ULN2803A Module Darlington Tube High Current Voltage Driver Voltage Protection Electric Component : Electronics). It'd be nice to be able to use Dupont connectors for Pi - ULN2083A, and for the ULN side of the ULN - SSR. I'd just have 2 SSRs, one for the element and one for a Chugger pump, and 1 DS18B20 for the kettle.

2.) For building an enclosure, does anyone have a recommendation for a way to include 2 panel mount power outlets that doesn't involve manually cutting a hole? My thought would be to use round power outlets like these (MEETOOT 2pcs 3Pin Power Outlet Socket Jack Connector Round US Type Industrial Plug Panel Mount Outlet Power Socket 15A 250V Universal Electrical AC Power Socket - - Amazon.com) with a junction box that has pre-punched 3/4 and 1" holes (DJC Supply Co. 12" x 12" x 3" PVC Plastic Junction Conduit Box with Pre Molded 3/4" & 1" Punch in holes - - Amazon.com). Based upon the power outlet dimensions, it looks like it should fit in the 1" holes, and the 3/4" would be nice for PG11 cable gland that fits the 110V power cord.

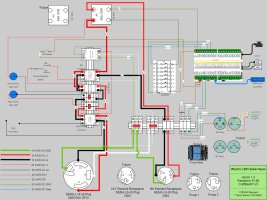

Wiring diagram taken from this YouTube video by Andrew Lynch:

1.) After reading through the monster CraftBeerPi HBT thread and watching a couple of YouTube videos, a couple folks suggested using a ULN2803A Darlington Array, to ensure that the Pi can trigger the element SSR and is less likely to be fried if something dumb happens. However, I didn't see much in the way of instructions (for the wiring inexperienced) about a permanemt setup using a ULN2803a without a breadboard or a CBP PCB. Would one of these boards work for the pictured wiring diagram? (Amazon.com: Voltage Driver Power Supply Module, 2Pcs ULN2803A Module Darlington Tube High Current Voltage Driver Voltage Protection Electric Component : Electronics). It'd be nice to be able to use Dupont connectors for Pi - ULN2083A, and for the ULN side of the ULN - SSR. I'd just have 2 SSRs, one for the element and one for a Chugger pump, and 1 DS18B20 for the kettle.

2.) For building an enclosure, does anyone have a recommendation for a way to include 2 panel mount power outlets that doesn't involve manually cutting a hole? My thought would be to use round power outlets like these (MEETOOT 2pcs 3Pin Power Outlet Socket Jack Connector Round US Type Industrial Plug Panel Mount Outlet Power Socket 15A 250V Universal Electrical AC Power Socket - - Amazon.com) with a junction box that has pre-punched 3/4 and 1" holes (DJC Supply Co. 12" x 12" x 3" PVC Plastic Junction Conduit Box with Pre Molded 3/4" & 1" Punch in holes - - Amazon.com). Based upon the power outlet dimensions, it looks like it should fit in the 1" holes, and the 3/4" would be nice for PG11 cable gland that fits the 110V power cord.

Wiring diagram taken from this YouTube video by Andrew Lynch: