6/11/2016 update

i was out all last week for business so no progress. i was supposed to be home on friday night but weather got me a bonus stay, sort of hosed my saturday but progress continues. started with more stuff in the mail:

rotating cip sprayball for my keg/carboy cleaner:

and some new magnets for my stir plate build:

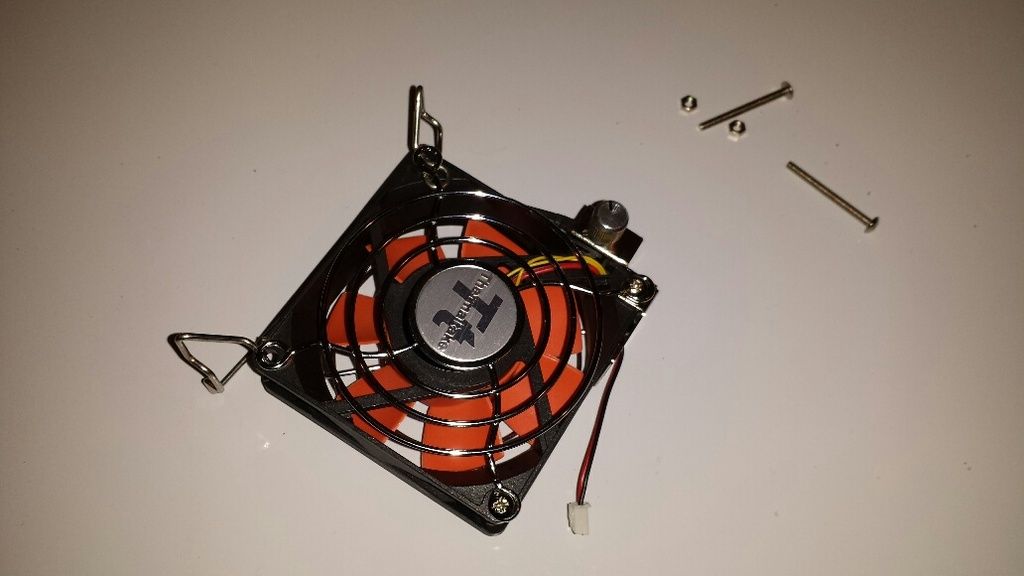

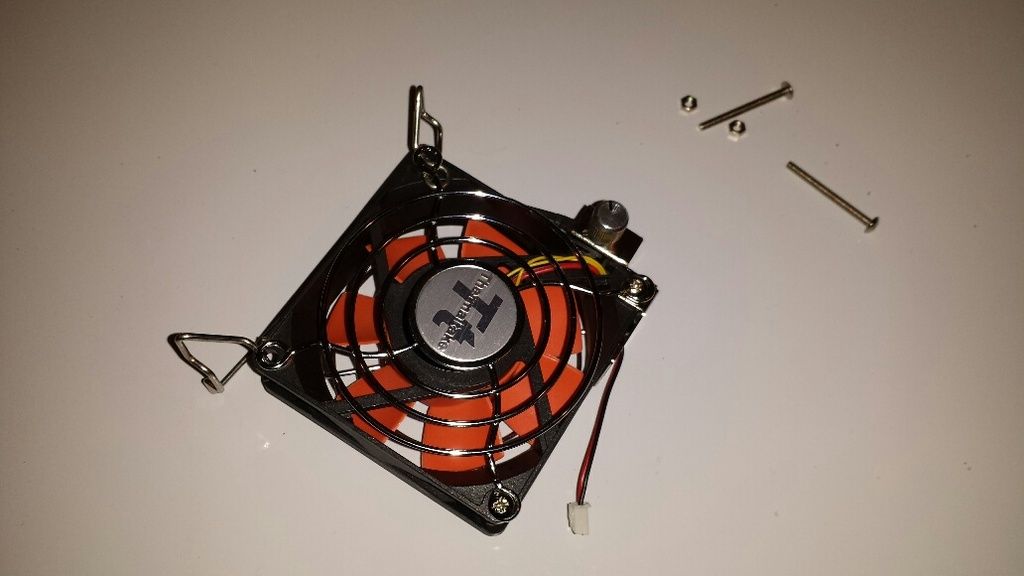

i really wanted to get a starter going so i tackled the stir plate project. similar to others, computer fans with magnets in a case of some type. started by removing the protective grills from the fans:

grills and speed adjustment removed:

idea is to glue a steel washer to the fan and attach magnets to the washer:

next comes the 'case' for the fan. i didn't have any boxes or similar lying around but i have scrap wood. plan is for a plywood 'top' on 2x4 'feet'. cutting the plywood to size:

center of board marked for drilling:

hole drilled:

mounting holes for the fan drilled and countersunk:

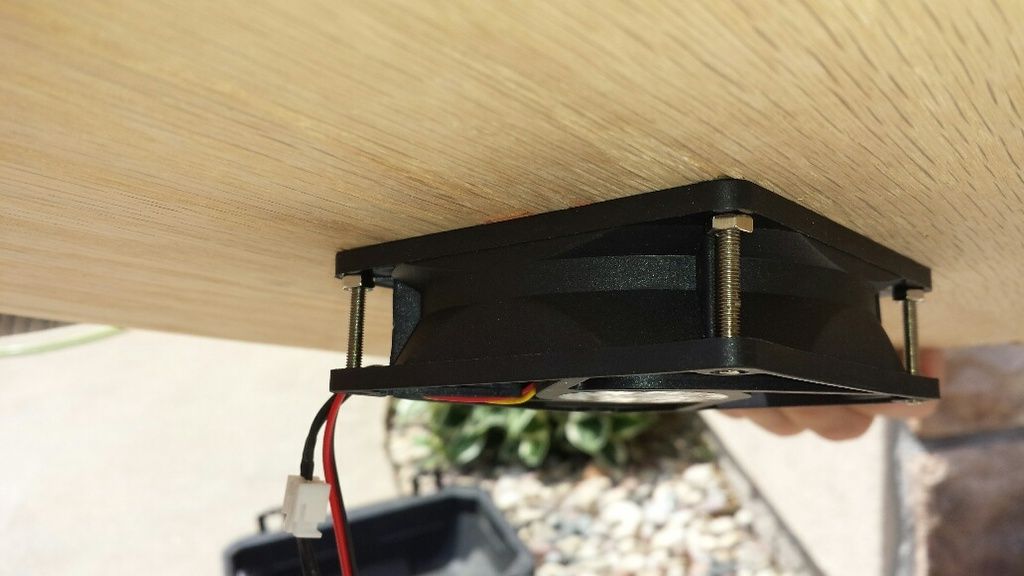

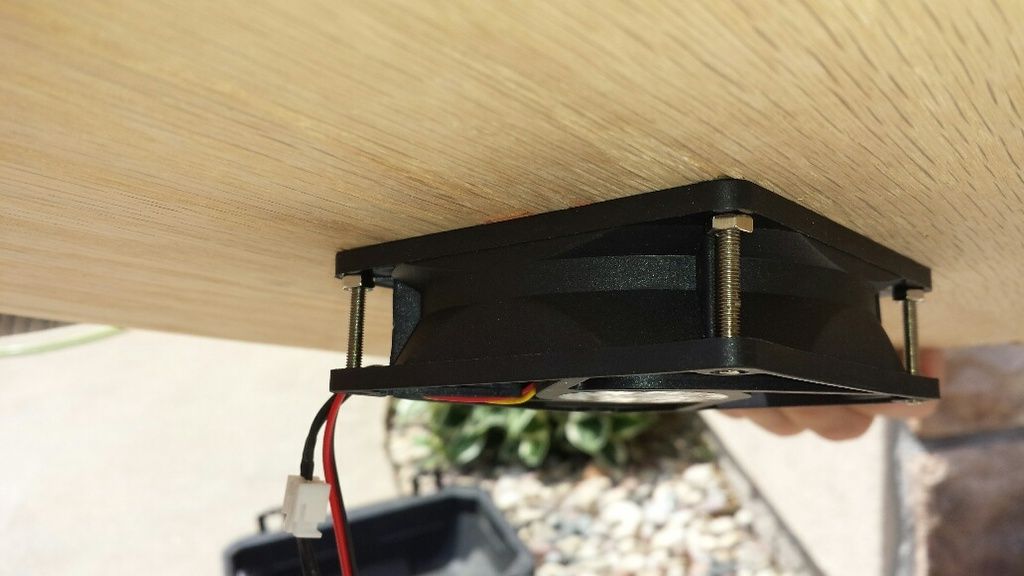

fan installed (with magnets):

a view from below. due to the thickness of the plywood, the bolts that held the protective grills on there are not long enough to pass through both sets of mounting holes at each corner of the fan. so i just nutted them through one mounting hole. this stir plate won't be seeing daily use so it should be fine:

scrap 2x4 cut up for the 'feet'. these are to raise the plywood off the surface it will rest on and keep space around the fan for air movement. the fan is one inch think so a 2x4 allows for a half inch of free air space under the fan:

mounting the feet to the corners:

and the plate in action:

time to start some real brewing activities. boiling up some light dme for a starter. it has been about 12 years since the last time i boiled up some dme, the smell took me back to our tiny apartment in chicago:

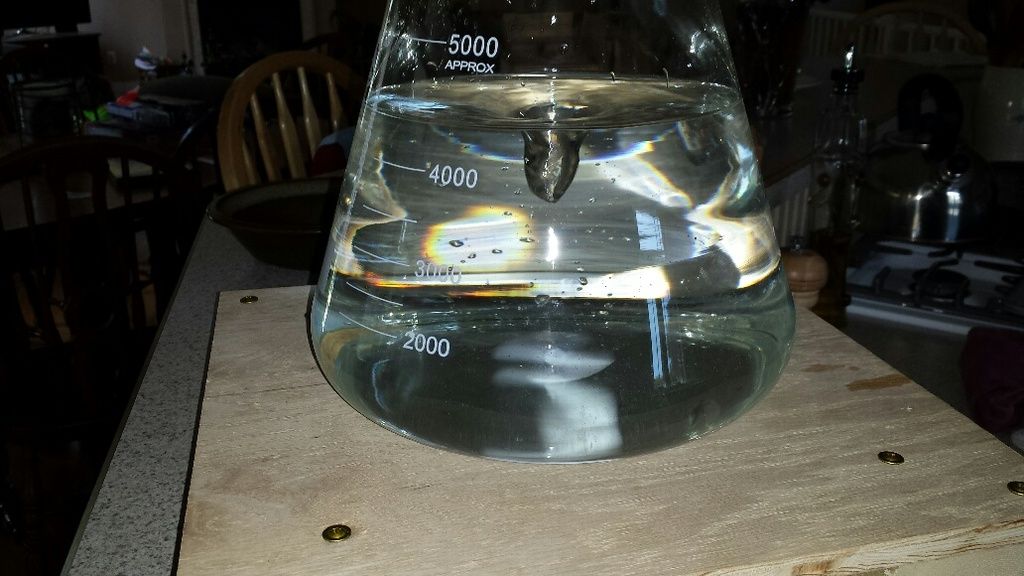

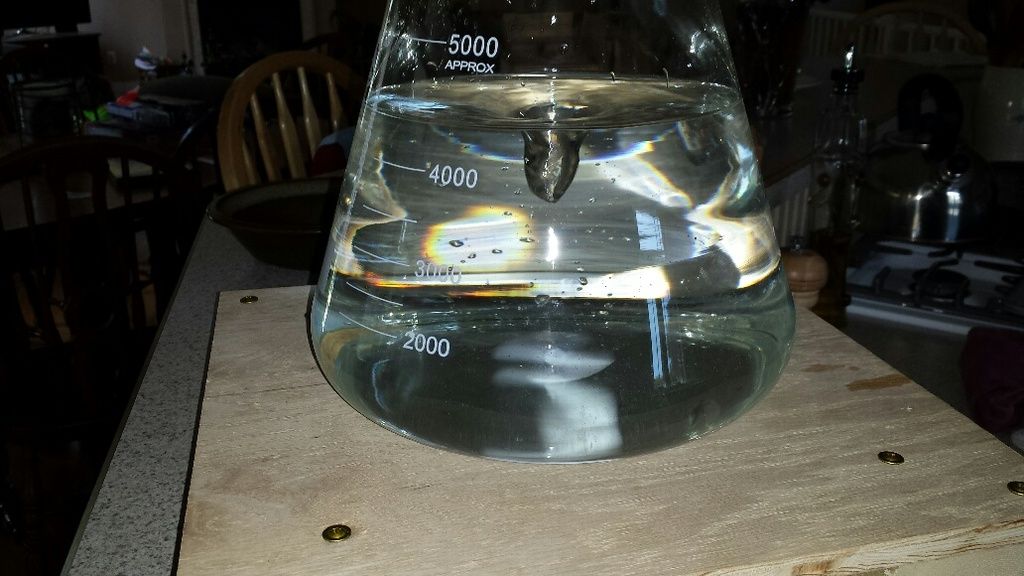

wort cooled, poured into sanitized flask, yeast pitched and stir plate in operation:

since i had my wood tools out, i figured i would make a small frame for my keg/carboy cleaner, for the carboy drying rack to rest on for stability. cutting scrap 1x1 to length:

and the completed frame, with stand attached. notice the fancy spray ball as well. alas, i cannot use it to the fullest, the carboy opening is too narrow to slide over the ball! damn! oh well, it still works with kegs. i'll just need to thread it on-off each time:

since i had the washer setup, i took the opportunity to wash all my carboys (four).

i was out all last week for business so no progress. i was supposed to be home on friday night but weather got me a bonus stay, sort of hosed my saturday but progress continues. started with more stuff in the mail:

rotating cip sprayball for my keg/carboy cleaner:

and some new magnets for my stir plate build:

i really wanted to get a starter going so i tackled the stir plate project. similar to others, computer fans with magnets in a case of some type. started by removing the protective grills from the fans:

grills and speed adjustment removed:

idea is to glue a steel washer to the fan and attach magnets to the washer:

next comes the 'case' for the fan. i didn't have any boxes or similar lying around but i have scrap wood. plan is for a plywood 'top' on 2x4 'feet'. cutting the plywood to size:

center of board marked for drilling:

hole drilled:

mounting holes for the fan drilled and countersunk:

fan installed (with magnets):

a view from below. due to the thickness of the plywood, the bolts that held the protective grills on there are not long enough to pass through both sets of mounting holes at each corner of the fan. so i just nutted them through one mounting hole. this stir plate won't be seeing daily use so it should be fine:

scrap 2x4 cut up for the 'feet'. these are to raise the plywood off the surface it will rest on and keep space around the fan for air movement. the fan is one inch think so a 2x4 allows for a half inch of free air space under the fan:

mounting the feet to the corners:

and the plate in action:

time to start some real brewing activities. boiling up some light dme for a starter. it has been about 12 years since the last time i boiled up some dme, the smell took me back to our tiny apartment in chicago:

wort cooled, poured into sanitized flask, yeast pitched and stir plate in operation:

since i had my wood tools out, i figured i would make a small frame for my keg/carboy cleaner, for the carboy drying rack to rest on for stability. cutting scrap 1x1 to length:

and the completed frame, with stand attached. notice the fancy spray ball as well. alas, i cannot use it to the fullest, the carboy opening is too narrow to slide over the ball! damn! oh well, it still works with kegs. i'll just need to thread it on-off each time:

since i had the washer setup, i took the opportunity to wash all my carboys (four).