badgerfan79

Well-Known Member

Anyone heard anymore?

I just got an email from Northern Brewer saying they have them exclusively.

Anyone heard anymore?

This thing looks pretty good. Any opinions or thoughts?

I just backed on the early bird

https://www.kickstarter.com/project...rmentation-made-easy?ref=category_recommended

O offense but I've discovered (the hard way) that these crowd funded projects ultimately result in disappointment. Either in actually delivering the product anywhere near the projected (promised) date or in actually functioning as promised, etc.

My advice is to keep your money in your pocket until or if it reaches the market and then evaluate true user experiences.

You'll probably be able to get it on Amazon long before the original backers at a good price, too.

A perfect example is the uKeg on Kickstarter!

We expect to ship the majority of the remaining orders throughout next week. We continued to ship throughout last week while completing production of the add ons to ensure everyones orders ship before the end of October as promised.

Northern Brewer committed to purchase The Catalyst before our Kickstarter launched, with this standing order we were able to move forward with production quicker then anticipated and this allowed us to commit to shipping all backer orders by the end of October. Without the commitment from them we would not have been able to commit to proceeding with production until we completed a successful Kickstarter campaign.

Again we truly appreciate your support and are working to get everyones order in hand as quickly as possible. I have been working hard on this project for 2 years and it is great to see so much support and demand for The Catalyst.

Thank you & Cheers,

Kyle Westfall

Founder - Craft a Brew

View attachment 373552

Mine came in yesterday. I'm posting an unboxing video to my YouTube channel this weekend. Search for "The Brew-Q" and subscribe! Appreciate any support in advance!

I hope everyone who buys one enjoys it. Two things for me: 1) I think it is overpriced and; 2) If it is truly exclusive to NB, I won't buy it even if the price goes down. Not a fan of the NB/AB/InBEV deal.

You can always just order directly from craft-a-brew themselves.

You can always just order directly from craft-a-brew themselves.

Thats correct, we have a short term exclusivity agreement with Northern Brewer which only allows CraftaBrew.com and NorthernBrewer.com to be the only online retailers. We will expand out distribution in the new year.

I'd doubt that *any* of the designers/producers which sell equipment to NB could possibly have had any knowledge before-the-fact of the AB buyout. It was pretty closely held.Did you know you were selling your souls when you signed?

Here's the unboxing video I did for this new fermenter. Cheers!

https://youtu.be/ZjcBBaY7GJU

Thats correct, we have a short term exclusivity agreement with Northern Brewer which only allows CraftaBrew.com and NorthernBrewer.com to be the only online retailers. We will expand out distribution in the new year.

I'd doubt that *any* of the designers/producers which sell equipment to NB could possibly have had any knowledge before-the-fact of the AB buyout. It was pretty closely held.

Solid Video. Thanks for doing it! It gave me a pause I hadn't thought of before. What do you think after having handled it.

Food containers like Snapware use the same style folding closure with a gasket and they always wear out and break. I am convinced they do it to make you buy more of their product.

Does the lid closure seem like it will crack and break with extended use?

Craftabrew - What's the wear estimation on the lid material?

thanks!

Ah yes, but what about selling me one for $129.00 or even $149.00 instead of $200.00?Thats correct, we have a short term exclusivity agreement with Northern Brewer which only allows CraftaBrew.com and NorthernBrewer.com to be the only online retailers. We will expand out distribution in the new year.

Ah yes, but what about selling me one for $129.00 or even $149.00 instead of $200.00?

Everyone forgets that a fast ferment with comparable accessories is about the same price anyway. Currently $185 on amazon.

The catalyst comes with a stand (fast ferment charges extra for), and trub catchers for this (mason jars) are dirt cheap, easier to sanitize, come in assorted sizes, and should last forever.

I was a kickstarter backer, and absolutely can't wait.

Honestly I had this concern too and I wanted our designers to go back to the drawing board at first but having cycle tested the latches over 500 times without any tearing or stretching I can honestly say that it is a closure that will last. We relentlessly tested everything to ensure The Catalyst would work as advertised, exceed expectation and stand the test of time. I hope everyone gets a chance to try it out or see it in action.

Maybe I'm missing something, but when you put that bottling attachment on and open the valve, doesn't it bubble up a bunch of air through your you're new beer?

Thanks for that update. Good to know. I am just starting brewing again after 15years. A lot of new equipment out there. This is on my short list of equipment to buy, as I am borrowing carboys now. Just the price is catching in my throat.

2 suggestions for future...

If you can do this in stainless for less than $250, you would beat out SSBrewtech for a lot of people. Second, consider selling the valve assembly as a stand alone. Modders would have a field day with it.

During my video unboxing of the Catalyst, there was a very large bubble of air that came through the water I used for leak testing. In all honesty, I really don't see it being an issue as usually we change out the jars only once and that is after the primary fermentation is done. There is so much CO2 in the beer at that point that the oxygen would get pushed out anyhow. The second time around, you would be closing the valve to remove the smaller yeast collection jar and then attaching the bottling/kegging tubing to move to bottles or a keg.

Bad comparison. First you pick the location where the FastFerment is listed the highest. Most places it is $99. Second, you mention no stand, well the Catalyst does not come with wall mounts, so you are even there. The wall mounts are one thing that puts the FastFerment over the Catalyst for me. But I am still digging the mason jar connection.

I noticed the big blurb as well lol. My thought was maybe opening the valve at the very beginning. Eventually, the yeast and trub will find its way there I would think.

During my video unboxing of the Catalyst, there was a very large bubble of air that came through the water I used for leak testing. In all honesty, I really don't see it being an issue as usually we change out the jars only once and that is after the primary fermentation is done. There is so much CO2 in the beer at that point that the oxygen would get pushed out anyhow. The second time around, you would be closing the valve to remove the smaller yeast collection jar and then attaching the bottling/kegging tubing to move to bottles or a keg.

Nope this is the worst time for oxidation. CO2 saturation will not stop oxidation of the beer. You'll need to somehow purge the second jar of oxygen before attaching or the beer will be oxidized.

You really only need to do this once other than right before fermentation, and you can just fill the jar with boiled water if you're worried about oxidation.

FYI,

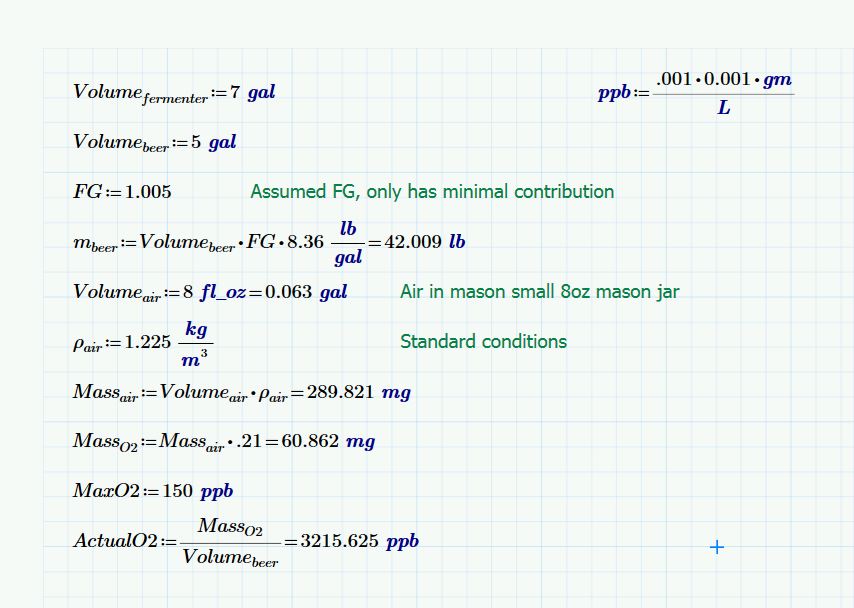

Per this presentation To prevent premature degradation of beer flavor due to packaged O2, the Total Packaged Oxygen (TPO) should be less than about 150 ppb (0.15 ppm).

Per Brewing Science and Practice TPO should be less than 200ppb and less than 100ppb should be picked up post fermentation.

Assuming that the beer has total 0ppb dissolved oxygen (DO) when the 8oz jar is screwed in and opened the O2 added from the air in the jar is approximately 3,000ppb, 15 times the total recommended DO.

It would be much preferable to add 8oz of StarSan than 8oz of air.

This isn't a product specific thing, many people use attachments on the bottom of other conicals.

Yes, this is something we have done before to test it and it greatly decreases the amount of air traveling through the beer. If this is done with the 8oz jar you are only introducing 8oz of water into 640 oz of beer which is a dilution of just over 1%.

Wouldn't this formula assume that all 8oz of air would be dissolved into the solution as it travels through the beer?

I think in practice much less then 1% of the air bubble would be absorbed into the beer as it travels through the solution, 99%+ will go through the beer and arrive on top of the fermenter.

At this time the CO2 will be heavier then the air in the headspace protecting it from any oxidation.

Also since there will still be dissolved CO2 in the beer it will continue to equalize with the headspace which will push even more CO2 into the headspace as the beer ages.

I think this would be a great fermentor for brewers trying to decrease their oxygen exposure with the exception of the bottling connector. I could go from fermentor to the in post on my purged corny with no or very little exposure.

That's where it falls short in this respect. That bottling adapter has too much volume. But I'm guessing it has to be that way to accommodate the swing of the large butterfly valve.

You could just discard the first pint or two of beer that pushes the air out of the adapter and tubing assuming that there are no voids that create air pockets. The diffusion of gas through the liquid beer would be small enough that the discarded beer would protect the rest of the beer.

You could if the volume of air was smaller. As soon as you open that butterfly valve, all that air bubbles up through the entire batch. I'm not saying that it's going to ruin your batch of beer, but some brewers go to great lengths to minimize the introduction of oxygen after fermentation, this product will float a big plug of air up through your beer when it comes time to transfer or bottle. I see this as a big drawback for $200.

Now, I could see installing my own valve out the side like on a steel conical, but for $200, I don't want to have to go about modifying it to make it suitable for my needs.

I did the math for oxidation with the small jar earlier in the thread. Didn't realize the bottling attachment had a big enough void to bubble through the beer! Figured you could just push it out like I used to do on conicals.

I did the math for oxidation with the small jar earlier in the thread. Didn't realize the bottling attachment had a big enough void to bubble through the beer! Figured you could just push it out like I used to do on conicals.By the way CraftaBrew is this pressure rated at all? If it can do 1-3psig it may make a good fermenter for me to wrap some discharge hose around for glycol temp control and use for small experimental batches.

Yea I'm one of them.I did the math for oxidation with the small jar earlier in the thread. Didn't realize the bottling attachment had a big enough void to bubble through the beer! Figured you could just push it out like I used to do on conicals.

Couldn't you just purge the jar(s) with CO2 before connecting? Use one of those handheld cartridge things. I realize it would not be 100% effective but should drastically reduce the amount of oxygen.

I also kickstarted this thing and am excited to start brewing again after a few years hiatus.

Enter your email address to join: