Merlin-CO

Active Member

[LONG POST...if you're willing to read!]

You guys are all bad influences! All these great DIY builds of all kinds of stuff that I've been following the last year or so drove me to desperation and I had to go and build a bar in my basement. Shame on you!

So now I'm sure you'll want to see the 'porn' shots of how it all went together - but I don't have a ton. I didn't think to grab the camera until 2/3 through the project. But I do have some shots of what kind of setup I did put together. Hopefully I can inspire a few others of you out there!

What I started with was a 'blank canvas' corner. Luckily for me (or possibly divine intervention) the space behind the wall is where the utility room was (the basement was already finished when I bought the place). And low & behold it was perfectly sized for my keezer!

Moving this back into the utility area allowed me to start doing some serious re-tuning of how I had my keezer setup. The biggest item was clearing the space taken up by the CO2 tank and moving it out. In this shot below you'll see that I'm running a two-regulator system with one going into a 3-way distribution panel. The other is free right now to pressurize kegs outside of the keezer for initial shake-priming.

Eventually I'll upgrade the 3-way to a larger panel to accommodate more kegs on two different pressures (so I can have a higher pressure group for Wheats/Wiezen's) as well as get a Nitro system setup - but that's later. You'll see that I have each tagged with a letter and color...

...and these match up with the appropriate CO2 supply line that has a zip-tie ID tag on each...

Inside the keezer I'll eventually be able to run 6-kegs with a 7th for a glycol-like system supply I'm running (with just water at the moment). I just finished installing the fan into the top today, and boy what a difference it makes in maintaining temp!

Right now the water/glycol system is just sitting in a bucket with a good pond pump I picked up at my local Lowes. The 'In' & 'Out' lines run in a group with 3 beer lines that I wrapped together from scratch.

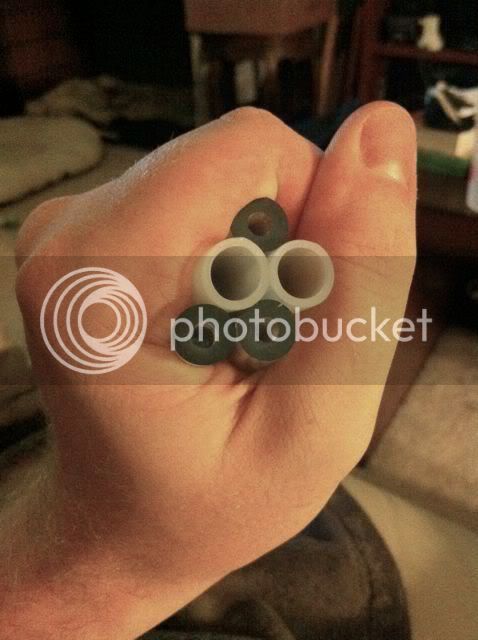

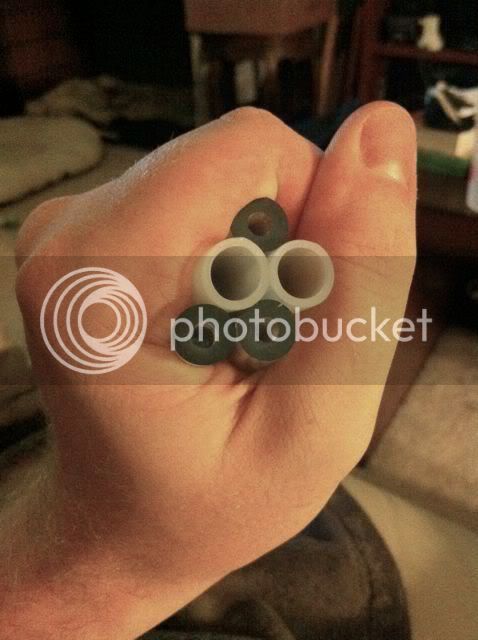

The 'In' & 'Out' lines run in a group with 3 beer lines that I wrapped together from scratch in this configuration (below). I used a plastic wrap to keep them together and then wrapped that in a layer of aluminum ducting tape and then wrapped that in a foam-rubber self-sealing pipe insulation section.

Right now I'm also running a Tee off of the glycol lines and that runs out of the keezer into a water bucket with some copper tubing in the water that helps to keep my currently fermenting Hefe at a decent temp (it's pretty warm here in Colorado, even in my basement).

[CONT'D]

You guys are all bad influences! All these great DIY builds of all kinds of stuff that I've been following the last year or so drove me to desperation and I had to go and build a bar in my basement. Shame on you!

So now I'm sure you'll want to see the 'porn' shots of how it all went together - but I don't have a ton. I didn't think to grab the camera until 2/3 through the project. But I do have some shots of what kind of setup I did put together. Hopefully I can inspire a few others of you out there!

What I started with was a 'blank canvas' corner. Luckily for me (or possibly divine intervention) the space behind the wall is where the utility room was (the basement was already finished when I bought the place). And low & behold it was perfectly sized for my keezer!

Moving this back into the utility area allowed me to start doing some serious re-tuning of how I had my keezer setup. The biggest item was clearing the space taken up by the CO2 tank and moving it out. In this shot below you'll see that I'm running a two-regulator system with one going into a 3-way distribution panel. The other is free right now to pressurize kegs outside of the keezer for initial shake-priming.

Eventually I'll upgrade the 3-way to a larger panel to accommodate more kegs on two different pressures (so I can have a higher pressure group for Wheats/Wiezen's) as well as get a Nitro system setup - but that's later. You'll see that I have each tagged with a letter and color...

...and these match up with the appropriate CO2 supply line that has a zip-tie ID tag on each...

Inside the keezer I'll eventually be able to run 6-kegs with a 7th for a glycol-like system supply I'm running (with just water at the moment). I just finished installing the fan into the top today, and boy what a difference it makes in maintaining temp!

Right now the water/glycol system is just sitting in a bucket with a good pond pump I picked up at my local Lowes. The 'In' & 'Out' lines run in a group with 3 beer lines that I wrapped together from scratch.

The 'In' & 'Out' lines run in a group with 3 beer lines that I wrapped together from scratch in this configuration (below). I used a plastic wrap to keep them together and then wrapped that in a layer of aluminum ducting tape and then wrapped that in a foam-rubber self-sealing pipe insulation section.

Right now I'm also running a Tee off of the glycol lines and that runs out of the keezer into a water bucket with some copper tubing in the water that helps to keep my currently fermenting Hefe at a decent temp (it's pretty warm here in Colorado, even in my basement).

[CONT'D]