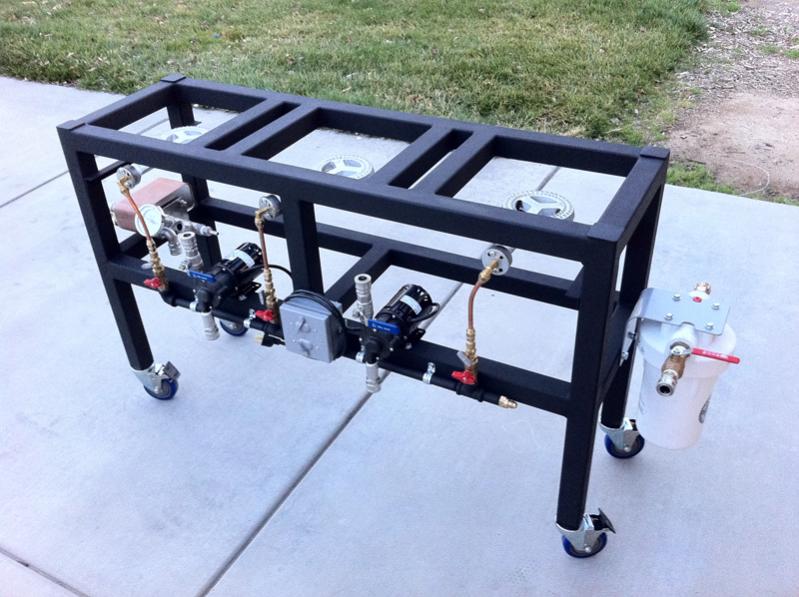

Done, but for the gas connection between the burners and the manifold. Camera battery died just after I moved the brew frame outside for a shot, lol.

So, right now I have pretty much what I built before, a short run of black pipe with Tees and ball valves off it, totals 10" or so.

This time I'm thinking of putting the tees directly below the burners, with something other than a ball valve. Trippr if you're around, I like your valves here:

-Can you tell me the type of make, and where I might get them?

I recall now, too, that that brewery I built 20 years ago had soft copper and compression fittings, IIRC. I Leak-tested each brewday. I think I'd like to maybe go to soft copper this time as well, as finding short runs of propane hoses isn't easy, and I don't feel like paying $75-90 for them, seems ridiculous to me anyway.

I thought this looked clean. Member, sorry, can't recall where I saw this:

Questions are: do you guys like copper - or does it wig you out a bit, and if so, what type of hose do you like (I also like that yellow flex-hose stuff, not sure if it comes in like 2' sections). Secondly, if I do go soft copper, I've only used compression, as I said. Something tells me flare's a better/safer option, yes? If so, just some guidance on what's involved - a flaring tool, for the copper? Anything else?

Final pic once the battery is charged, lol.

Thanks all, once again.