You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

diagram

- Thread starter BrewBeemer

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

OMJ

Well-Known Member

the diagram is too small to see and when I zoomed in it was too blurry to read

Hang Glider

Beer Drinker

+1

please repost

please repost

TipsyDragon

Well-Known Member

yea way to small to be read by humans. what is it a diagram of?

BrewBeemer

Well-Known Member

Okay, i am trying again.

TipsyDragon

Well-Known Member

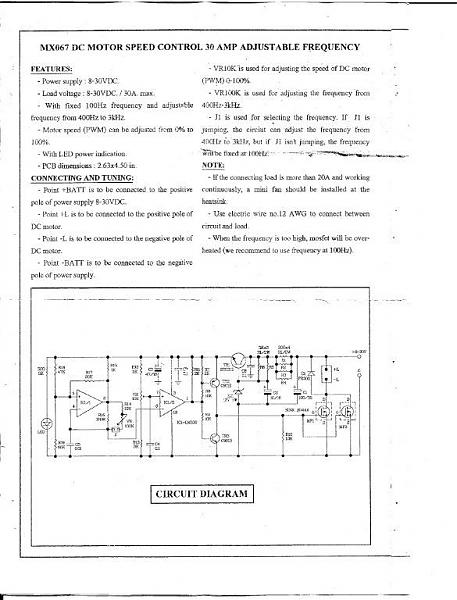

ok way better ..... what about it?

BrewBeemer

Well-Known Member

This is a PWM with a fixed frequency of 100 Hz, remove the jumper and get 350 to 3K Hz adjustable with the pot. I need to change the frequency to 5 Hz the low end to 50 Hz or what the Hz ends at with the pot controlling IC/1. This will allow me to pulse, flush and check the balance of fuel injectors more to their normal operating range of 600 to 6,000 rpms.

I haven't a clue what to change to alter this frequency down lower plus not doing any damage to this kit I assembled.

Any resistance or parts change values will be greatly appreciated for this project.

I'm due for a smog check and running out of time. With 24 injectors to flush and pick i'll be able to find a balanced set of 8 with flow. I made a sight glass cylinder out of a 750 ML wine bottle on my diamond saw. I have a electronic timer to repeat tests plus a Burette tube to measure in cc's the output volumes. Sorry way off topic of the HBT ya think?

In my email box I have a much larger scan photo as an attachment but can not get this onto the forum.

Email me i'll send the diagram back that is larger in my email, i'm at [email protected]. Again thanks for the intrest and help. Carl.

I haven't a clue what to change to alter this frequency down lower plus not doing any damage to this kit I assembled.

Any resistance or parts change values will be greatly appreciated for this project.

I'm due for a smog check and running out of time. With 24 injectors to flush and pick i'll be able to find a balanced set of 8 with flow. I made a sight glass cylinder out of a 750 ML wine bottle on my diamond saw. I have a electronic timer to repeat tests plus a Burette tube to measure in cc's the output volumes. Sorry way off topic of the HBT ya think?

In my email box I have a much larger scan photo as an attachment but can not get this onto the forum.

Email me i'll send the diagram back that is larger in my email, i'm at [email protected]. Again thanks for the intrest and help. Carl.

This would be a lot easier for you to do if you had an oscilliscope. It has been literally years since I did this kind of stuff, but to lower the frequency you want to increase either the resistance or capacitance in the circuit. Assuming the potentiometer on the left is the one you're talking about, you can probably just stick another resistor in series with that to tune it to a lower frequency range.

The amount of combined resistance times capacitance is inversely proportional to the frequency. So if you're trying to reduce the frequency by 10x you need 10x more combined resistance and capacitance.

The amount of combined resistance times capacitance is inversely proportional to the frequency. So if you're trying to reduce the frequency by 10x you need 10x more combined resistance and capacitance.

BrewBeemer

Well-Known Member

This would be a lot easier for you to do if you had an oscilliscope. It has been literally years since I did this kind of stuff, but to lower the frequency you want to increase either the resistance or capacitance in the circuit. Assuming the potentiometer on the left is the one you're talking about, you can probably just stick another resistor in series with that to tune it to a lower frequency range.

The amount of combined resistance times capacitance is inversely proportional to the frequency. So if you're trying to reduce the frequency by 10x you need 10x more combined resistance and capacitance.

The cap (C5 in diagram) that's in the circuit now is a 0.01 value, the resistor (R16) to the IC is 330K ohm. I want to lower the Hz by a value of 20. So I would need a cap 20 times larger or 0.2 in value as Kladue PM'ed me plus the resistance of 6.6 meg ohm resistor if i'm thing straight here correct? This does not have to be nats azz Hz just close to the Hz that a standard inject recieves from an idle on up to nearing a redline. This at 600 to 6K rpm's for a better volume check thru their operating Hz zone. I can read the Hz and PW with my Fluke 87 meter.

I also have HBT member Kladue on my PM with a reply. Thanks.

Right or you could use a combination of capacitor and resistor to lower the frequency. It doesn't have to be all one or the other.

BrewBeemer

Well-Known Member

With Kladues PM reply I replaced the 0.01cap with a .22uf, (0.20 was not availble at Radio Shack). It now has a fixed 4.85Hz, close enough for the low idle speed testing off the timer. When switched to variable it starts at 19Hz with the pot control up to 149Hz. This covers the range in Hz that commercial units produce i've run across on the net. I'm very happy and can move forward on this project. Many thanks to all that repled to my posting. A special thanks to Kladue as he has replied to me a couple times.

Carl.

Carl.

Similar threads

- Replies

- 27

- Views

- 714

- Replies

- 6

- Views

- 424

- Replies

- 11

- Views

- 1K