Automatic Control with the Avantco burner... Sure? Anything can be automated with a slight hack (right)?!?!

I have been working on this for a while now (OK, more thinking), and one may say it's still at the "idea" stage... But with two young kids I barely have time to brew!

Anyway, here are my plans that I hope to be testing out soon and I hope it sparks a few more ideas here for Automatic Control.

Goal: Automatic Control of the Mash temperature of course!

1. Add two wire pairs to the underside of the PCB to control the Up/Down switches. Status: Done! See pictures.

2. Add two SSR's to the wire pairs that will activate the up/down switches. The switches had around 5 volts DC on them (if I remember correctly) and when shorted together it will act like the switch was pressed. Status: Need to find the SSR's.

3. Recirculating mash. Status: Done!

4. Write an application that will control the SSR's based on the mash temp and have a cool interface and have control over my entire brew process! Status: STARTED!

5. Tune and Test! Status: Coming soon...

6. Brew!!! Repeat steps 5 and 6 again and again! Status: Coming soon...

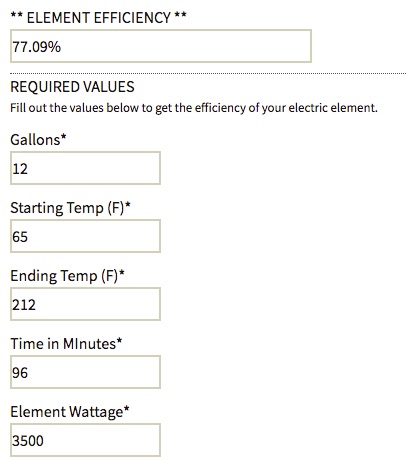

I'm using Vb.net to a USB controller with several I/O, one would be able to do this with a raspberry pi and/or arduino just as easy. Tuning the controller is going to be the best part and what I'm looking forward to the most! There are only 10 steps from 500 to 3500 watts. 500 isn't off but in my experience it's close enough. I do plan on using the Watt mode, but will also try out the temp mode when tuning as the burner does have some control already and it may help... I don't remember home many steps there are while in the temp mode?

Concerns I have:

Loud beeping noise? (Would hate to wake up the kids!) First, I will try adding some tape over the speaker, if that isn't enough I will just remove the speaker all together.

Switching too fast or too much? Start with a 10 second delay before making any changes and adjust as needed. But, maybe it doesn't matter at all and one would just switch away... Not sure, but the tighter the control means more accurate temps and it also means more switching... Also Faster the better!

No feedback to tell me the power level or step? May take some more digging into the PCB to find a spot to monitor and tie it back to one of the controller's input.

Again, not complete yet... But I wanted to share what I have so far to help spark other ideas!

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)