borealis

Well-Known Member

I am hoping to use it on my electric range outlet which is supported by a 50 amp breaker in the panel. The induction burner has a NEMA 6-20P plug.

Note: If you require a NEMA L6-20 connection instead of the L6-30, simply mention it in the notes section when you order and we will make the change. It will be the same price.

NO! An appliance should never be plugged into an outlet with a higher rating than the appliance. A table lamp may only use half an amp, but the lamps wiring is rated for 15 amps. Plugging the lamp (or your hotplate) into a 50 amp outlet could cause the wiring to catch fire before the fuse or breaker blows if there is some kind of malfunction.

I don't claim to know code, but agree with what's been said about the circuit breaker being rated to protect the wiring to the receptacle, not the device plugged into the receptacle. And that you can plug in anything drawing up to the breakers rated amperage. Here’s a company that sells the type of adapter that you’re looking for.

240v?. . . After looking more in my panel, i have a line with a 20 amp breaker that used to be dedicated to the blower fan . . .

Thanks for the replies. Alternatively, after looking more in my panel, I have a line with a 20 amp breaker that used to be dedicated to the blower fan of an old garage heater. Could I just use that line and have someone wire it to the appropriate outlet? It would be easier to make the stove outlet work though.

You could have gone with a "slow blo" fuse if they make them that big which I think they do...

I guess any voltage below 233.33 would put you over 15 amps at the 3500watt setting.

Don't know the electrical load nature of this thing but decreasing voltage doesn't necessarily mean increasing current. For some devices that's true, for others it's not.

Anyone know if an induction heater works as a "resistive device" or is somehow different?For purely resistive devices, like a normal heating elements, it's the opposite - high voltage = high current and low voltage = low current.

Thanks tbelczak! This is unfortunate. I have being saving up for this and other items to get my basement electric setup done. I unfortunately have already spent out the money for the electrical and specifically for this induction cooktop. I guess I will still end up going with this and just be careful on the power setting/usage. I think in my electrical(very limited) research, the 240v can vary on your location +/- a few volts. Is it possible your house may have a lower voltage coming in (or did for that short period of time) causing it to blow? I guess any voltage below 233.33 would put you over 15 amps at the 3500watt setting.

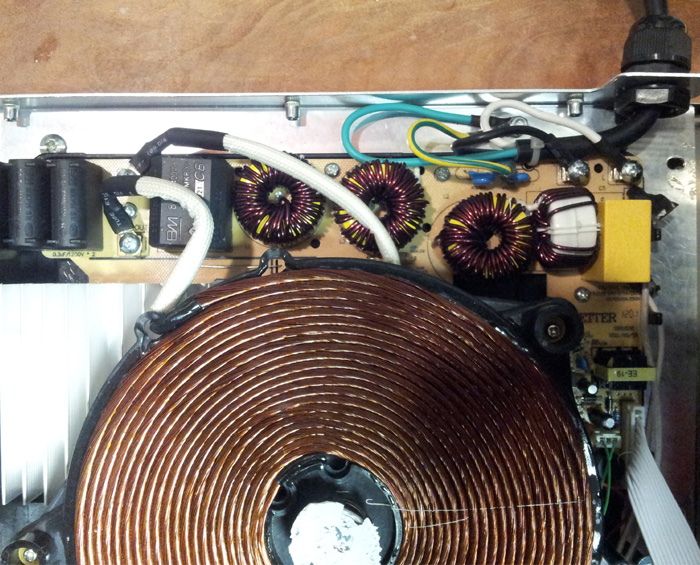

Since you did open it up...did you potentially see anyway to provide an external control for the power? Something that could be useful for temp controlling?

I think the issue is heat inside the case. In a hot environment you have to de-rate the fuse. Fortunately, by putting the fuse outside the case you have effectively solved the problem

Even without the heat, 15 amps seems a little light. The line voltage can vary by 5%, so if the load is constant, the actual current could be 14 - 16 amps.

Boiling a big pot is making the thing work pretty hard. I would have used a 20.

For purely resistive devices, like a normal heating elements, it's the opposite - high voltage = high current and low voltage = low current.

Hard to say what caused your problem, but as a comparison, over the last two years I've brewed 28 batches with the same induction hob. Most were 11 gallon boils that lasted at least 75 minutes (not counting the time it takes to get to a boil) and the unit was run mostly at the full 3500 watt setting. The power coming into my house is in the 235 to 240 volts range.If it blows again, I will just run the cooktop at the 3100W setting in the future.

Exactly what I was thinking of doing, induction and the megapot. What size pot is that? How well has it been working for you, any issues with boils or anything? I am trying to plan out my brewery right now and if this is working good for you, I think I will go that way. I have been impressed with the megapots for the price.