vanilla_prison

New Member

- Joined

- May 5, 2020

- Messages

- 3

- Reaction score

- 3

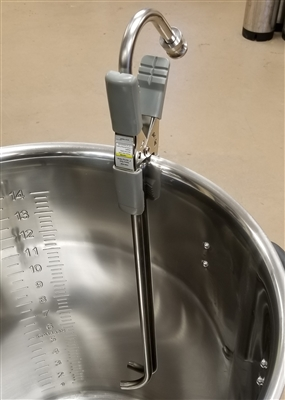

I can’t seem to find a straight answer for my question via googling. There seems to be much debate on whirlpooling with or without cooling. For context, I brew with an Anvil Foundry 10.5 and I have a Riptide pump with a 21” swirly arm. So doing whirlpools is an easy task. My question is about when exactly to whirlpool or cool, considering I’m going for trub reduction in the fermenter? I don’t do any whirlpool hop additions, so this is specifically about wanting beer as clear as possible. So should I:

1) Run wort through CFC while doing whirlpool, rest, then transfer to fermenter

2) Whirlpool, rest, then run through CFC into fermenter

3) Recirculate through CFC back into kettle until cool, then whirlpool, rest, and transfer

Seems like a dumb question, but beforehand I used an immersion chiller and whirlpooled by hand simply to cool faster before transfer. So with my new pump, CFC, and swirly arm a different world is opened up. Thanks!

1) Run wort through CFC while doing whirlpool, rest, then transfer to fermenter

2) Whirlpool, rest, then run through CFC into fermenter

3) Recirculate through CFC back into kettle until cool, then whirlpool, rest, and transfer

Seems like a dumb question, but beforehand I used an immersion chiller and whirlpooled by hand simply to cool faster before transfer. So with my new pump, CFC, and swirly arm a different world is opened up. Thanks!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)