I also found a site that custom makes multilevel switches... but I bet they are $$$$$$ expensive $$$$$

http://www.auberins.com/index.php?main_page=product_info&cPath=7_32&products_id=339

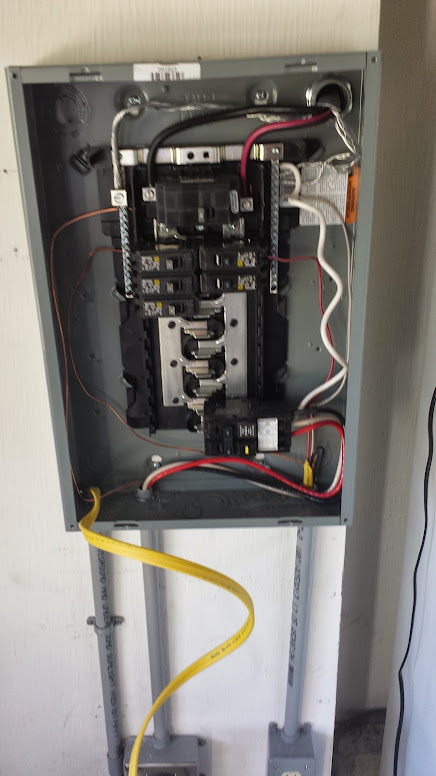

Here she is

I also found a site that custom makes multilevel switches... but I bet they are $$$$$$ expensive $$$$$

to bad im going BIAB because this would be perfect.

I also noticed that auber put a gasket in for a weldless install. Anyone know off hand if this is food safe or should I just assume, I'll be replacing this.

Use some industrial Velcro... easy to remove, but should stay in place nicely

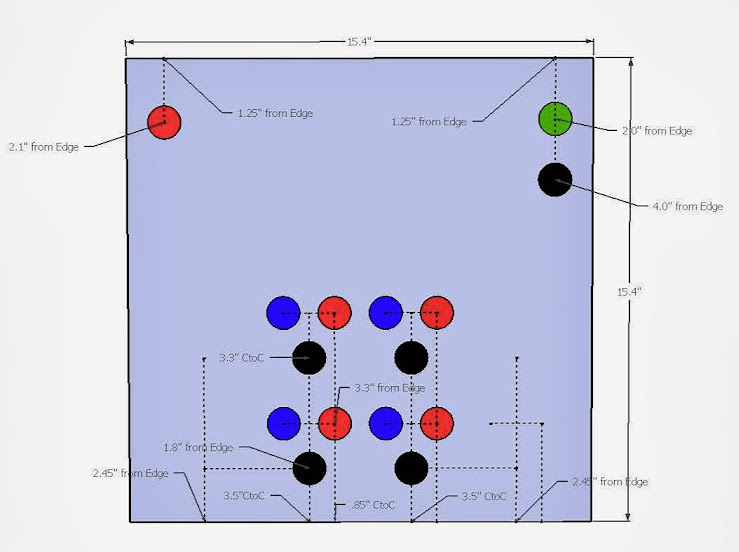

Brilliant! I am getting some right nowJust waiting on the last few pieces to decide how I'm going to lay out the box and then on to drilling the rest of the holes! I've laid out the inside probably a dozen times while trying to decide how I'm going to go with it. Picked up a couple DIN mounts for the contactors so that they can be mounted much easier and need less holes

Since you're using DIN rails, I suggest getting some "DIN-Rail Mount High-Amp Distribution Blocks" from McMaster-Carr. I bought some 6367T22's from them. I used them for taking the big 6-gauge wires which were the power inputs for my panel and splitting those into four 10-gauge wires as power outputs, which ran to other sections of the control panel.

They take up a lot less space than the old-fashioned terminal blocks.

The Cloney the Piner was much appreciated at the tailgate! Looking forward to your next batch :rockin:

I also found a site that custom makes multilevel switches... but I bet they are $$$$$$ expensive $$$$$

Rather than one switch with both functions, why not one each for high water and low water levels. A little stainless steel pipe, and these can be at whatever height you want. http://www.sourcingmap.com/tank-water-level-sensor-stainless-steel-float-switch-p-139200.html

Keep in mind that the float switch in the posted link is not the correct one for mounting through the side of a kettle. A curve neck is requied like this one: Curve Water Level Sensor Liquid Steel Float Switch Pool

Hope this helps.

thats gonna be tight with your pump outlet

I ran into an issue. I can't seem to pull the locking mechanism off the enclosure. It looks like its almost glued down. Does anyone have any suggestions? If not, I'm considering cutting it off and ordering one off Granger to replace it with.

Give us a close-up pic of the inside door.

The knurled ring on the back of the lock thing unscrews and the whole thing comes off. You can see it in your 2nd picture.

That means tonight/tomorrow can start the wiring... I think.

That means tonight/tomorrow can start the wiring... I think.