You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Treehouse Brewing Julius Clone

- Thread starter kaz4121

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Little_Lebowski

Well-Known Member

- Joined

- May 31, 2016

- Messages

- 209

- Reaction score

- 39

Currently on tap. Turned out fantastic. I used the northeast IPA recipe on beersmith and just bumped the flaked oats up to 1#. I also added half the dry hops to the primary on day 7 and you could literally see the oily haze flowing down into the beer. I think these primary hop additions definitely contribute to this sought after haze.

I don't know if this has been posted, but I know oxygen has been talked about

https://www.homebrewtalk.com/showthread.php?t=580532

It would seem, at least to me, that the control of oxygen is incredibly important. I'm going to be trying my best on this next batch in order to reduce oxidation as much as possible

https://www.homebrewtalk.com/showthread.php?t=580532

It would seem, at least to me, that the control of oxygen is incredibly important. I'm going to be trying my best on this next batch in order to reduce oxidation as much as possible

Oxygenation of finished beer, is an important factor to control, if the beer will be sitting around for a while. Generally hoppy beers like this that are consumed fairly fast, are pretty forgiving with oxygen exposure. Commercial breweries worry about shelf stability and so DO is a big concern with packaged product.

DO in finished beer can be quite easy to avoid, especially if you are kegging. The best deterrent is healthy active yeast - dry hopping (which can introduce oxygen) near the tail end of fermentation can reduce DO in finished beer, because the yeast will scrub it out as its finishing up its job (there are other benefits to this, but that's another topic).

Also having the ability to keg your beer will allow you to purge the container of O2 before putting beer into it, greatly reducing the amount of O2 exposure. The purging procedure we use at my brewery goes: 5 psi on vessel then purge, repeat 2 more times, then up the psi to racking pressure.

If you don't have kegs, bottle conditioning your beer with healthy yeast will do a good job of greatly reducing DO in the finished product. Hope this helps.

DO in finished beer can be quite easy to avoid, especially if you are kegging. The best deterrent is healthy active yeast - dry hopping (which can introduce oxygen) near the tail end of fermentation can reduce DO in finished beer, because the yeast will scrub it out as its finishing up its job (there are other benefits to this, but that's another topic).

Also having the ability to keg your beer will allow you to purge the container of O2 before putting beer into it, greatly reducing the amount of O2 exposure. The purging procedure we use at my brewery goes: 5 psi on vessel then purge, repeat 2 more times, then up the psi to racking pressure.

If you don't have kegs, bottle conditioning your beer with healthy yeast will do a good job of greatly reducing DO in the finished product. Hope this helps.

Gustatorian

Well-Known Member

- Joined

- Apr 1, 2015

- Messages

- 638

- Reaction score

- 23

Read through this entire feed in 2 days. Subscribed!

Gustatorian

Well-Known Member

- Joined

- Apr 1, 2015

- Messages

- 638

- Reaction score

- 23

Totally new to the forum, but I swallowed up this feed in like 2 days and I built a recipe based on some key points that were made.

This is the recipe I've built up thus far based on past knowledge, what I've read from this forum, and the links that people have so kindly provided ...PLEASE let me know what you think.

Brew is for 6 gallons of beer into the fermentor. I always brew more because I want to make sure I have 5 gallons going into the keg.

WATER:

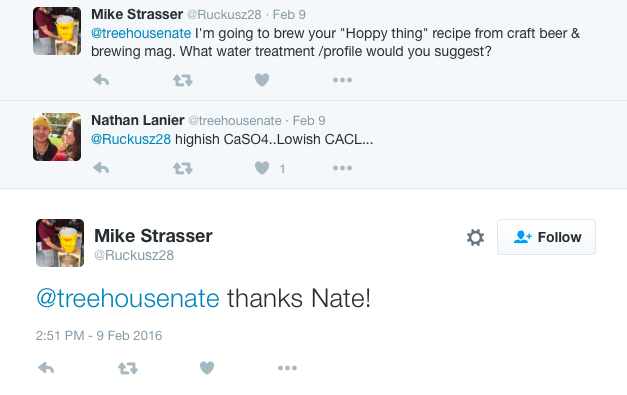

I'm working with Ozarka 100% Natural Spring Water which is essentially RO. I plan on adding 10g Gypsum, 10g CaCl2, 10g Epsom Salt into all approximately 12 gallons of water (no-sparge system). I came upon this addition based on the tweet that Nate posted about keeping Sulfate High and Chloride "lowish" (which I assume is just lower as compared to Sulfate). Based on this alteration and the acid malt I'm adding, I should get a Mash pH around 5.2 at room temp. I wanted it lower based on the low pH comments people are posting within the forum.

MALT: I'll spare you the pounds bc my efficiency is terrible. Also, I built the grist bill based on what Nate has provided from "Hoppy Thing", recipes within the forum, and I added a good helping of acid malt based on the post #431 in which Annie Johnson said to keep the water softer yet make sure the pH is low. This was difficult info to take in based on the Nate's tweet mentioned earlier. Anyways, here it is...

2-Row (92.3%)

C60 (3%)

Honey Malt (2.1%)

Acid Malt (2.6%)

Plan on mashing at 148 to hit 1.013 with Wyeast 1318 (1.013 being a number we've all landed on as the target)

KETTLE HOPS: I'm shooting between 58-72 IBUS. Closer to 58 actually. That was the IBU provided by the lab tested Julius can. The 72 IBU number is based on the IBU provided from Nate's "Hoppy Thing" recipe. Per Beersmith, the following charges will yield 61 IBUs (close enough).

Columbus, 1 oz, 60 min

Centennial, 0.5 oz, 20 min

Amarillo, 1 oz, 20 min

STEEP/WHIRL POOL: WP will be for 90 minutes (I know this seems overkill, but I have good results with longer steep times), kettle top on, and starting at 140ºF.

Centennial, 1 oz

Amarillo, 1 oz

Simcoe, 1 oz

Citra, 2 oz

After the steep, I'll be pitching into my 7 G conical at 66ºF, pitching 1318, and fermenting at 66ºF until fermentation has slowed immensely. At that point, I'll turn off my temp control, dry-hop with 4 oz Citra, and allow the temp to free rise (likely to around 69-71ºF) until fermentation has stopped.

Next, I plan on close-circuit transferring the beer into a corny keg via CO2 pressure. Prior to the transfer, I'll place a mesh tube around my liquid out tube, sanitize, and drop 6 oz. Citra into bottom, purge heavily with CO2, and then transfer beer from conical.

Once keg is filled, I'll carb for a week at room temp, then remove CO2, invert keg for 24 hours, return keg to it's non-inverted position and cold-crash for 24 hours before pouring.

SPECS: (per Beersmith)

OG: 1.066

FG: 1.013

IBU: 61

ABV: 6.9%

SRM: 10

Concerns:

My Chloride to Sulfate ratio is 0.58. Per EZ Water Calc, any ratio below 0.77 could sharpen/accentuate the bitterness of the beer (which I never get a sharp bitterness in Julius). Should I reconfigure my water profile?

The amount of acid malt. I usually never break 1.5% of the grist bill with acid malt, and now I'm at 2.6%. Do you think this will be too sour or will the C60 and Honey help with the balance?

Any other concerns or suggestion are welcome. I'm all ears!

TIA!

This is the recipe I've built up thus far based on past knowledge, what I've read from this forum, and the links that people have so kindly provided ...PLEASE let me know what you think.

Brew is for 6 gallons of beer into the fermentor. I always brew more because I want to make sure I have 5 gallons going into the keg.

WATER:

I'm working with Ozarka 100% Natural Spring Water which is essentially RO. I plan on adding 10g Gypsum, 10g CaCl2, 10g Epsom Salt into all approximately 12 gallons of water (no-sparge system). I came upon this addition based on the tweet that Nate posted about keeping Sulfate High and Chloride "lowish" (which I assume is just lower as compared to Sulfate). Based on this alteration and the acid malt I'm adding, I should get a Mash pH around 5.2 at room temp. I wanted it lower based on the low pH comments people are posting within the forum.

MALT: I'll spare you the pounds bc my efficiency is terrible. Also, I built the grist bill based on what Nate has provided from "Hoppy Thing", recipes within the forum, and I added a good helping of acid malt based on the post #431 in which Annie Johnson said to keep the water softer yet make sure the pH is low. This was difficult info to take in based on the Nate's tweet mentioned earlier. Anyways, here it is...

2-Row (92.3%)

C60 (3%)

Honey Malt (2.1%)

Acid Malt (2.6%)

Plan on mashing at 148 to hit 1.013 with Wyeast 1318 (1.013 being a number we've all landed on as the target)

KETTLE HOPS: I'm shooting between 58-72 IBUS. Closer to 58 actually. That was the IBU provided by the lab tested Julius can. The 72 IBU number is based on the IBU provided from Nate's "Hoppy Thing" recipe. Per Beersmith, the following charges will yield 61 IBUs (close enough).

Columbus, 1 oz, 60 min

Centennial, 0.5 oz, 20 min

Amarillo, 1 oz, 20 min

STEEP/WHIRL POOL: WP will be for 90 minutes (I know this seems overkill, but I have good results with longer steep times), kettle top on, and starting at 140ºF.

Centennial, 1 oz

Amarillo, 1 oz

Simcoe, 1 oz

Citra, 2 oz

After the steep, I'll be pitching into my 7 G conical at 66ºF, pitching 1318, and fermenting at 66ºF until fermentation has slowed immensely. At that point, I'll turn off my temp control, dry-hop with 4 oz Citra, and allow the temp to free rise (likely to around 69-71ºF) until fermentation has stopped.

Next, I plan on close-circuit transferring the beer into a corny keg via CO2 pressure. Prior to the transfer, I'll place a mesh tube around my liquid out tube, sanitize, and drop 6 oz. Citra into bottom, purge heavily with CO2, and then transfer beer from conical.

Once keg is filled, I'll carb for a week at room temp, then remove CO2, invert keg for 24 hours, return keg to it's non-inverted position and cold-crash for 24 hours before pouring.

SPECS: (per Beersmith)

OG: 1.066

FG: 1.013

IBU: 61

ABV: 6.9%

SRM: 10

Concerns:

My Chloride to Sulfate ratio is 0.58. Per EZ Water Calc, any ratio below 0.77 could sharpen/accentuate the bitterness of the beer (which I never get a sharp bitterness in Julius). Should I reconfigure my water profile?

The amount of acid malt. I usually never break 1.5% of the grist bill with acid malt, and now I'm at 2.6%. Do you think this will be too sour or will the C60 and Honey help with the balance?

Any other concerns or suggestion are welcome. I'm all ears!

TIA!

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$33.98

DYKWSWYX Heavy Duty Brewing Gloves (1 Pair) - 55CM Long Chemical Resistant Plastic Gloves for Beer & Wine Making, Cleaning, Homebrew Equipment Protection

wuhanshijiayangzhiyimaoyiyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

I'm pretty sure that a ratio of 1:1 for sulfate chloride is what you should be aiming for to get the mouth feel. Or at least somewhere close

Here's my feedback based on my experiences. To each their own, but this is what works for me.

I came upon this addition based on the tweet that Nate posted about keeping Sulfate High and Chloride "lowish" (which I assume is just lower as compared to Sulfate).

Nice! That was me who tweeted him about that. I'm glad that topic has been helping others. I know he said higher sulfates, but I've had better results with the opposite. 1:0.5 ratio of calcium chloride to gypsum based on my tap profile.

WY1056 works great as well. 1318 is okay, but I've had better luck and closer results with 1056, followed by conan, than 1318.

Columbus, 1 oz, 60 min

Centennial, 0.5 oz, 20 min

Amarillo, 1 oz, 20 min

I think the above will work, but I'd move the centennial and amarillo addition to the 5 minute mark or later.

STEEP/WHIRL POOL: WP will be for 90 minutes (I know this seems overkill, but I have good results with longer steep times), kettle top on, and starting at 140ºF.

Centennial, 1 oz

Amarillo, 1 oz

Simcoe, 1 oz

Citra, 2 oz

I've never steeped that low so make sure you follow up with your results. I have whirlpooled at 150 with a similar amount of hops and the beer came out too bitter to drink. I'm currently using about 1.5-1.8 oz of hops/gallon total per batch and it's acceptable. Too much hops in the whirlpool gives me a lot of vegetal/raw hop flavor that IMO ruins the beer.

After the steep, I'll be pitching into my 7 G conical at 66ºF, pitching 1318, and fermenting at 66ºF until fermentation has slowed immensely. At that point, I'll turn off my temp control, dry-hop with 4 oz Citra, and allow the temp to free rise (likely to around 69-71ºF) until fermentation has stopped.

I find that the haze is achieved without the use of adjuncts by dry hopping at peak fermentation (2-3 days in) and then again in the keg.

Next, I plan on close-circuit transferring the beer into a corny keg via CO2 pressure. Prior to the transfer, I'll place a mesh tube around my liquid out tube, sanitize, and drop 6 oz. Citra into bottom, purge heavily with CO2, and then transfer beer from conical.

I've found that 2-3oz in the keg (2.5 gallon keg) is a powerful nose. Almost stronger than what i've experienced with TH, but good nonetheless.

Once keg is filled, I'll carb for a week at room temp, then remove CO2, invert keg for 24 hours, return keg to it's non-inverted position and cold-crash for 24 hours before pouring.

I recommend fining the keg with gelatin during the cold crash to remove any hop matter/yeast still in suspension. It really cleans up the flavor and makes it more enjoyable. I've only had to do this when using Conan and Yeast Cultured from TH. I'm fairly certain they use something along the lines of a conan strain.

Gustatorian

Well-Known Member

- Joined

- Apr 1, 2015

- Messages

- 638

- Reaction score

- 23

Here's my feedback based on my experiences. To each their own, but this is what works for me.

Thanks for the input!

I went ahead and made a few alterations to the raw materials/process.

First off, going with WLP-001. Although I've had success with London III in the past, I can't imagine it's subtle fruitiness will shine through amidst the onslaught of hops (could be wrong though, and maybe they subtle yeast element assists with the "waves of flavor" in Julius). Due to the yeast change, I'll alter my mash temp to 152 and, per beersmith, come in around 1.013, ABV still at 6.8%.

Additionally, I changed the minerals to favor Cholride. C/S ratio is now around 1.6. Based on the water calculators I use, I think I'll have a mash pH of 5.2ish.

Also, I'm moving my late hops (Amarillo and Centennial) to the 5 minute mark. Due to this, I've increase the amount from 0.5 oz each to 1 oz each, in order to compensate for the IBU loss. I know Amarillo makes a great mid-late boil addition, I do fear the loss of major hop oils though.

Everything else looks to be the same. I went to the LHBS to crush my grain and chewing the malt gave me a lackluster flavor with a few of my choices. The 2-Row and C60 seemed a bit bland (I'm used to sticking to MO and GP). Hoping that they'll lend a nice backbone.

Yeast starter was made today and on the stir plate. Slated for brewing on Thursday!

Here's my feedback based on my experiences. To each their own, but this is what works for me.

Can you share the details or a screen shot of that tweet?

This guy? Came out Allright. I ran out of citra and subbed in nelson. It's really floral and white grapey.

This was brewed with conan (omega dipa). It's drinking well at about 2 weeks of age.

View attachment 1466042083312.jpg

This was brewed with conan (omega dipa). It's drinking well at about 2 weeks of age.

View attachment 1466042083312.jpg

Quick question on dry hopping...

I'm planning on splitting up 6 total oz of hops into 2 dry hop additions. The first towards the end of fermentation and the second a few days after that. Since I don't have a means of closed transfer to a secondary, it will all be done in the primary.

I typically wouldn't leave a dry hop in there for more than 6 days (usually 4-6). So, if the first addition goes in on day 3 and the second on day 6... I think I could bottle on day 10 with the first addition having been in there for 7 days and the second for 4.

Does that sound about right? Or would you adjust the timing of the additions in any way? I'm mostly worried about that first 3 oz addition sitting in there for 7 days. Of course, this all assumes fermentation goes as planned.

I'm planning on splitting up 6 total oz of hops into 2 dry hop additions. The first towards the end of fermentation and the second a few days after that. Since I don't have a means of closed transfer to a secondary, it will all be done in the primary.

I typically wouldn't leave a dry hop in there for more than 6 days (usually 4-6). So, if the first addition goes in on day 3 and the second on day 6... I think I could bottle on day 10 with the first addition having been in there for 7 days and the second for 4.

Does that sound about right? Or would you adjust the timing of the additions in any way? I'm mostly worried about that first 3 oz addition sitting in there for 7 days. Of course, this all assumes fermentation goes as planned.

Quick question on dry hopping...

I'm planning on splitting up 6 total oz of hops into 2 dry hop additions. The first towards the end of fermentation and the second a few days after that. Since I don't have a means of closed transfer to a secondary, it will all be done in the primary.

I typically wouldn't leave a dry hop in there for more than 6 days (usually 4-6). So, if the first addition goes in on day 3 and the second on day 6... I think I could bottle on day 10 with the first addition having been in there for 7 days and the second for 4.

Does that sound about right? Or would you adjust the timing of the additions in any way? I'm mostly worried about that first 3 oz addition sitting in there for 7 days. Of course, this all assumes fermentation goes as planned.

Primary term may not be done by day 3 it could be day 4 or 5. Check your fg on your second dry hop. If it's at your number and it's been 10 days it's prob done but Conan cleans up more if you let it sit a little longer. If you keg than I'd just dry hop at tail end of primary whenever that is for you then 3 days later then transfer.

ryancrook

Well-Known Member

what temperature are you dry hopping at? 7 days is an average time to dry hop but I think it's best to taste the beer each day until you achieve the flavor you want/like. This study: http://brulosophy.com/2015/10/26/dry-hop-length-long-vs-short-exbeeriment-results/ is a good read for you. there's another study on the same site that talks about quantity and temp of dry hopping.

Primary term may not be done by day 3 it could be day 4 or 5. Check your fg on your second dry hop. If it's at your number and it's been 10 days it's prob done but Conan cleans up more if you let it sit a little longer. If you keg than I'd just dry hop at tail end of primary whenever that is for you then 3 days later then transfer.

Unfortunately, I'm definitely going to have to bottle this one. Given that, I'm thinking I might just check the gravity on day 3 and see how things are progressing. If it is slower than expected, I might consider waiting on the first addition and/or add them all at one time with a goal of ensuring fermentation is complete before the hops have been in there too long.

The big wild card is that I'm not sure what yeast my LHBS will have. Sort of a last min thing and might even be 1056. If so.... I'll just add flour and oats and whatever else I can find to make it cloudy.

Unfortunately, I'm definitely going to have to bottle this one. Given that, I'm thinking I might just check the gravity on day 3 and see how things are progressing. If it is slower than expected, I might consider waiting on the first addition and/or add them all at one time with a goal of ensuring fermentation is complete before the hops have been in there too long.

The big wild card is that I'm not sure what yeast my LHBS will have. Sort of a last min thing and might even be 1056. If so.... I'll just add flour and oats and whatever else I can find to make it cloudy.

The wait and see is the best approach. I used to add all dry hops at once on day 10 but now I'll do one addition at the end of primary ferment that could be day 4-6 depending on yeast and temps. I would not add flour but that's just me I don't see the need but some people use it to effect so to each their own.

The wait and see is the best approach. I used to add all dry hops at once on day 10 but now I'll do one addition at the end of primary ferment that could be day 4-6 depending on yeast and temps. I would not add flour but that's just me I don't see the need but some people use it to effect so to each their own.

I am going to wing this one on short notice and no ingredients locked down other than a call to my LHBS confirming they have Citra...

1. Grain bill similar to Nate's "Hoppy Thing" but with the C60 dialed down equal to the honey and 1lb of flaked oats added to get me to 1065 on my system in Beersmith.

7g pre boil... 6 into the fermentor... and 5 in the keg/bottle.

- 13lb 2 row

- .25lb C60

- .25lb Honey

- 1lb Flaked Oats

2. One bittering charge equaling about 40 IBU. Figure an oz Magnum or so.

3. 12oz additional hops split into 4 additions of 3oz each. Any combination of...

Citra

Galaxy

Amarillo

Mosaic

Centennial

... etc.

- 3oz flameout

- 3oz whirlpool (30 mins from 160 - 140 degrees or so)

- 3oz active fermentation dry hop (day 4)

- 3oz second dry hop (a few days after the first)

Yeast - Might go with Conan or 1318 or 1056. Depends on what my LHBS has tomorrow.

I will report on how it goes!

This guy? Came out Allright. I ran out of citra and subbed in nelson. It's really floral and white grapey.

This was brewed with conan (omega dipa). It's drinking well at about 2 weeks of age.

No, the "tweet that Nate posted about keeping Sulfate High and Chloride 'lowish'"

No, the "tweet that Nate posted about keeping Sulfate High and Chloride 'lowish'"

Here you go:

I love how he is specific lol. I can't blame him, that's his bread and butter. I've actually found the opposite to be more conducive for hop forward beers. 2 chloride : 1 sulfate additions.

In terms of dry hopping, i'm adding half of my dry hops about 2-3 days into fermentation and the rest in the keg or 24 hours before bottling. My latest batch, i put half of my dry hops into the primary fermenter just before pitching my yeast. Results to follow next week.

In terms of dry hopping, i'm adding half of my dry hops about 2-3 days into fermentation and the rest in the keg or 24 hours before bottling. My latest batch, i put half of my dry hops into the primary fermenter just before pitching my yeast. Results to follow next week.

I meant to give an update on this. It turned out fantastic. A few modifications were needed (link) Huge notes of pineapple and mango. Underlying notes of other tropical fruit, citrus and light pine/dank/earthiness, and a candy-like citrus fruit note I get from amarillo. It was difficult to tell what was hops, and if anything was contributed by the yeast itself. I thought it was kind of grassy and yeasty at first, but a little bit of cold conditioning really helped it out. That may have been keg clogging and trub issues though. After sitting in the keg for a few weeks, it actually dropped relatively clear. Relatively to the milkshake consistency we can get at least. It was still hazy, but translucent at least.

I really liked the interplay of the hops. Citra and mosaic play great together in my experience.

I won a local homebrew competition with it. Nothing fancy or major, but I'm proud of it. It was also well received at the homebrewer events I took it to.

Next time I'm going to play with the amount of oats. I keep hearing more oats. It was good as is, but there is always room for improvement. I'd love to do a side by side with Conan and 1318 as well. A "down under" version with maybe Galaxy, Nelson Sauvin, and maybe Waimea or Wai-iti sounds like it could be glorious as well.

I really liked the interplay of the hops. Citra and mosaic play great together in my experience.

I won a local homebrew competition with it. Nothing fancy or major, but I'm proud of it. It was also well received at the homebrewer events I took it to.

Next time I'm going to play with the amount of oats. I keep hearing more oats. It was good as is, but there is always room for improvement. I'd love to do a side by side with Conan and 1318 as well. A "down under" version with maybe Galaxy, Nelson Sauvin, and maybe Waimea or Wai-iti sounds like it could be glorious as well.

This is the recipe I came up with. It's vaguely based off of Hoppy Things, and influenced by some other beers of this style like Heady Topper and HopHands. I'd appreciate any insight or suggestions. The carafoam feels a pretty unnecessary considering the wheat and oats. It's not all that dissimilar to a grain bill that Ruckusz28 posted maybe 20 pages or so ago, and noslenwerd posted recently. I'm looking to brew this in a few weeks perhaps.

Projected for 5.5 gallons at 65% efficiency. I figure I'll lose a lot to trub.

11 lbs 8.0 oz Pale Malt (2 Row) US (2.0 SRM) Grain 78.0 %

1 lbs 8.0 oz White Wheat Malt (2.4 SRM) Grain 10.2 %

12.0 oz Oats, Flaked (1.0 SRM) Grain 5.1 %

8.0 oz Carafoam (2.0 SRM) Grain 3.4 %

4.0 oz Caramel/Crystal Malt - 60L (60.0 SRM) Grain 1.7 %

4.0 oz Honey Malt (25.0 SRM) Grain 1.7 %

Bittering: (may use hopshot if I order soon)

0.50 oz Columbus (Tomahawk) [14.00%] (60 min) (First Wort Hop) Hops 31.3 IBU

1.00 oz Citra [11.10%] (15 min) Hops 12.0 IBU

1.00 oz Amarillo Gold [8.50%] (15 min) Hops 9.2 IBU

Flameout:

1.50 oz Citra [11.10%] (0 min) Hops -

0.75 oz Amarillo Gold [8.50%] (0 min) Hops -

0.75 oz Mosaic [12.50%] (0 min) Hops -

Hopstand @ 170-180 for 30min

1.50 oz Citra [11.10%] (30 min) (Aroma Hop-Steep) Hops -

0.75 oz Amarillo Gold [8.50%] (30 min) (Aroma Hop-Steep) Hops -

0.75 oz Mosaic [12.50%] (30 min) (Aroma Hop-Steep) Hops -

Dry Hop (will probably split in half. Half as fermentation is subsiding, and half after totally attenuated)

3.00 oz Citra [11.10%] (Dry Hop 7 days) Hops -

1.50 oz Amarillo Gold [8.50%] (Dry Hop 7 days) Hops -

1.50 oz Mosaic [12.50%] (Dry Hop 7 days) Hops -

1 Pkgs London Ale III (Wyeast Labs #1318) Yeast-Ale

ultravista

Well-Known Member

Subscribing

I mashed mine at 153F for 60min. I will admit my last beer finished a bit high (1.018 IIRC), but I've heard that can be an issue with first generation Conan. I was shooting for around 1.013. With the soft mouthfeel and fruit flavors it was kind of hard to tell the gravity was higher than intended. I used Bootleg Biology's The Magi. While I made a starter, the pack was a little old.

stickyfinger

Well-Known Member

This is an interesting exBeeriment that is relevant to this thread:

http://brulosophy.com/2016/06/20/th...g-in-a-ne-style-pale-ale-exbeeriment-results/

http://brulosophy.com/2016/06/20/th...g-in-a-ne-style-pale-ale-exbeeriment-results/

- Joined

- Dec 16, 2015

- Messages

- 935

- Reaction score

- 355

This is an interesting exBeeriment that is relevant to this thread:

http://brulosophy.com/2016/06/20/th...g-in-a-ne-style-pale-ale-exbeeriment-results/

Something interesting/annoying I noticed.

Right up front he aknowledges that water profiles play a big role in NE beers, but he chooses to ignore that and eliminate it. But isn't the point to experiment with the full style? I guess you could say you wanted to test one variable at a time, but shouldn't you then go and test the other?

While NE-style ales are commonly made with water thats very high in chloride, we decided it would be best to go with a balanced water profile in order to reduce the impact it has on haziness. With the treated strike water all warmed up, Ed incorporated the grains and hit his target mash temperature.

The whole point was to experiment with haziness, so why leave out a variable that might be contributing.

He even brings it back up at the end

When it comes to this newfangled style, it seems to me theres more to it than just grist, chloride levels, and yeast alone, but rather the interplay of various factors that contribute to what has become a hot commodity among the craft beer drinking community.

I'd like to see the same thing done but with the water profile included.

stickyfinger

Well-Known Member

I'd guess that the yeast strain and malt are more important than the salts. I've used very high chloride levels and gotten crystal clear beers pretty quickly. You're right that it might not taste quite right without the chloride though.

I thought is was much more interesting that the two beers didn't differ in flavor given that one was fined. I always thought fining would hurt a hoppy beer. I need to try some side-by-sides with gelatin again.

I thought is was much more interesting that the two beers didn't differ in flavor given that one was fined. I always thought fining would hurt a hoppy beer. I need to try some side-by-sides with gelatin again.

stickyfinger

Well-Known Member

Looks like he used 100ppm of chloride and 100 ppm of sulfate (after reading the post where he developed the recipe.)

This isn't entirely new news, but a new brewer in portland seems to be chatty about the NEIPA style

http://www.marketwatch.com/story/how-portlands-65th-craft-brewer-has-learned-to-compete-2016-07-08

What I realized is that it was a combination of things to make a New England style of IPA to get that hop flavor. Here in Portland, we saw the IBU wars over the last few years and, fortunately, they have gone away. Nobody’s bragging about a 100 IBU beer anymore. What we’re seeing now, from my perspective, are beers that are more balanced, lighter in color, less crystal and caramel malts, beers that have a higher protein content through wheat and oats. The protein in the style is one of the defining factors — they’re hazy, and you can’t get through that.

People look at our beers and say: “You have too much yeast in suspension.” What it comes down to is educating people that there is some yeast in every beer — we don’t filter, we don’t fine, we don’t centrifuge — but we cold crash all of our beer, drop the yeast out and then do a heavy dry hopping. We dry hop about two and a half to three gallons per barrel. When you dry hop that heavily, you get hop polyphenols that are basically tannins that saturate beer with oils.

Without protein content from wheat or oats, those oils eventually drop out. What we’re finding to be the defining characteristic of our beers is this marriage of protein and hop oil saturation. What’s happening is that those two are binding. You have this hop oil stuck in suspension and when you pour it into a glass, you’re tasting the hop oil.

We’re spending a lot of money on hops, and if these hops are going to drop out, it feels like you’re wasting money. That’s the beauty of the New England-style IPA, and that’s why that style is blowing up across the nation. I’m not a hop scientist, but this is just my observation from making it over and over again. It’s not something that we’re keeping a secret: People know you’re using flaked wheat or oats and leaving those hop oils in suspension. It’s like a hefeweizen: That’s not cloudy because of the yeast; it’s because of the wheat.

http://www.marketwatch.com/story/how-portlands-65th-craft-brewer-has-learned-to-compete-2016-07-08

What I realized is that it was a combination of things to make a New England style of IPA to get that hop flavor. Here in Portland, we saw the IBU wars over the last few years and, fortunately, they have gone away. Nobody’s bragging about a 100 IBU beer anymore. What we’re seeing now, from my perspective, are beers that are more balanced, lighter in color, less crystal and caramel malts, beers that have a higher protein content through wheat and oats. The protein in the style is one of the defining factors — they’re hazy, and you can’t get through that.

People look at our beers and say: “You have too much yeast in suspension.” What it comes down to is educating people that there is some yeast in every beer — we don’t filter, we don’t fine, we don’t centrifuge — but we cold crash all of our beer, drop the yeast out and then do a heavy dry hopping. We dry hop about two and a half to three gallons per barrel. When you dry hop that heavily, you get hop polyphenols that are basically tannins that saturate beer with oils.

Without protein content from wheat or oats, those oils eventually drop out. What we’re finding to be the defining characteristic of our beers is this marriage of protein and hop oil saturation. What’s happening is that those two are binding. You have this hop oil stuck in suspension and when you pour it into a glass, you’re tasting the hop oil.

We’re spending a lot of money on hops, and if these hops are going to drop out, it feels like you’re wasting money. That’s the beauty of the New England-style IPA, and that’s why that style is blowing up across the nation. I’m not a hop scientist, but this is just my observation from making it over and over again. It’s not something that we’re keeping a secret: People know you’re using flaked wheat or oats and leaving those hop oils in suspension. It’s like a hefeweizen: That’s not cloudy because of the yeast; it’s because of the wheat.

stickyfinger

Well-Known Member

This isn't entirely new news, but a new brewer in portland seems to be chatty about the NEIPA style

Thanks! That's a fun read. I wish I could find more inside info on this style. I think I'm starting to understand it better. I think the yeast and flaked grains are definitely the major things that separate them from the west coast ipa style. I don't remember if i said this before, but, on a whim, I split a 10 gallon batch of wit bier (45ish% flaked wheat, 45ish% pils and 10% flaked oats) into two beers. I turned one half into a "NE IPA." It only is about 4.2% ABV, but it has great mouthfeel, is super hazy, even after cold conditioning and over 1 week of serving from the keg! It has HUGE hop presence that is not really dying very easily! There must be something to the protein holding the hop deliciousness in suspension!

grassfeeder

Well-Known Member

- Joined

- Jan 30, 2014

- Messages

- 424

- Reaction score

- 107

This isn't entirely new news, but a new brewer in portland seems to be chatty about the NEIPA style

http://www.marketwatch.com/story/how-portlands-65th-craft-brewer-has-learned-to-compete-2016-07-08

What I realized is that it was a combination of things to make a New England style of IPA to get that hop flavor. Here in Portland, we saw the IBU wars over the last few years and, fortunately, they have gone away. Nobodys bragging about a 100 IBU beer anymore. What were seeing now, from my perspective, are beers that are more balanced, lighter in color, less crystal and caramel malts, beers that have a higher protein content through wheat and oats. The protein in the style is one of the defining factors theyre hazy, and you cant get through that.

People look at our beers and say: You have too much yeast in suspension. What it comes down to is educating people that there is some yeast in every beer we dont filter, we dont fine, we dont centrifuge but we cold crash all of our beer, drop the yeast out and then do a heavy dry hopping. We dry hop about two and a half to three gallons per barrel. When you dry hop that heavily, you get hop polyphenols that are basically tannins that saturate beer with oils.

Without protein content from wheat or oats, those oils eventually drop out. What were finding to be the defining characteristic of our beers is this marriage of protein and hop oil saturation. Whats happening is that those two are binding. You have this hop oil stuck in suspension and when you pour it into a glass, youre tasting the hop oil.

Were spending a lot of money on hops, and if these hops are going to drop out, it feels like youre wasting money. Thats the beauty of the New England-style IPA, and thats why that style is blowing up across the nation. Im not a hop scientist, but this is just my observation from making it over and over again. Its not something that were keeping a secret: People know youre using flaked wheat or oats and leaving those hop oils in suspension. Its like a hefeweizen: Thats not cloudy because of the yeast; its because of the wheat.

Great Notion has some fantastic beers however I still don't see their IPA's being top of class with the NE guys quite yet. Their sours I think steal the show there.

grassfeeder

Well-Known Member

- Joined

- Jan 30, 2014

- Messages

- 424

- Reaction score

- 107

.

I was lucky enough to get 8 cans of Julius from the brewery. Definitely very citrus in aroma and flavour. The biggest thing I noticed though is that its not that bitter. I don't think the IBU's are any more than maybe 50.

Little_Lebowski

Well-Known Member

- Joined

- May 31, 2016

- Messages

- 209

- Reaction score

- 39

I was lucky enough to get 8 cans of Julius from the brewery. Definitely very citrus in aroma and flavour. The biggest thing I noticed though is that its not that bitter. I don't think the IBU's are any more than maybe 50.

Yeah and I don't miss that bitterness at all. Trying to get away from that standard "1 oz at 60" addition myself and start experimenting with 45-30 min additions around .5-.75 or even FWH additions to cut that bitterness way back.

stickyfinger

Well-Known Member

I wonder if all of the bitterness in some of these beers is just coming from the hop stand and the dry hop? I don't think the 60 minute addition is really even needed, unless you like more bitterness in your beer. I'd rather get a dryer finish using gypsum than boost the bitter character.

grassfeeder

Well-Known Member

- Joined

- Jan 30, 2014

- Messages

- 424

- Reaction score

- 107

I wonder if all of the bitterness in some of these beers is just coming from the hop stand and the dry hop? I don't think the 60 minute addition is really even needed, unless you like more bitterness in your beer. I'd rather get a dryer finish using gypsum than boost the bitter character.

I did 1oz at 30 minutes in my last NE style for 30 IBU's, it's soon tropical fruit forward it honestly needs just a bit more. I think 45 IBU's would be perfect. I actually blended it 75 mine and 25 local IPA that's mosaic/citra forward and it's perfect.

I did 1oz at 30 minutes in my last NE style for 30 IBU's, it's soon tropical fruit forward it honestly needs just a bit more. I think 45 IBU's would be perfect. I actually blended it 75 mine and 25 local IPA that's mosaic/citra forward and it's perfect.

What's your hopping schedule? I'd like to compare it to mine.

My last batch size was about 3 gallons and I added .2 oz of Columbus at 60 and then 3 oz at 180* WP. Still came out a little too bitter for me. The last one I made I moved the bitter to 30 minutes and bumped down to .1 oz. it's still finishing up in the fermenter right now. I know Columbus can be a little harsh though.

There's a Bissell Brothers SWISH clone on HBT and the clone was based off of a email from one of the Bissell bros. They used .1 oz for bittering and 2 oz at 10 min and then 4 oz in a WP for a 5 gallon batch. I believe SWISH is a DIPA and only comes in around 50-60 IBU (measured) for a DIPA. Which is pretty low.

I believe the super low bitterness/high hop flavor helps provide that mouthfeel, in addition to water and a lower carbonation.

grassfeeder

Well-Known Member

- Joined

- Jan 30, 2014

- Messages

- 424

- Reaction score

- 107

What's your hopping schedule? I'd like to compare it to mine.

My last batch size was about 3 gallons and I added .2 oz of Columbus at 60 and then 3 oz at 180* WP. Still came out a little too bitter for me. The last one I made I moved the bitter to 30 minutes and bumped down to .1 oz. it's still finishing up in the fermenter right now. I know Columbus can be a little harsh though.

There's a Bissell Brothers SWISH clone on HBT and the clone was based off of a email from one of the Bissell bros. They used .1 oz for bittering and 2 oz at 10 min and then 4 oz in a WP for a 5 gallon batch. I believe SWISH is a DIPA and only comes in around 50-60 IBU (measured) for a DIPA. Which is pretty low.

I believe the super low bitterness/high hop flavor helps provide that mouthfeel, in addition to water and a lower carbonation.

That beer is here: https://www.homebrewtalk.com/showthread.php?t=586762

Yeah and I don't miss that bitterness at all. Trying to get away from that standard "1 oz at 60" addition myself and start experimenting with 45-30 min additions around .5-.75 or even FWH additions to cut that bitterness way back.

it's all going to depend on your system. I don't think there's anything wrong with bittering at 60. I put all of my flavor hops in post boil. since I don't have a means of keeping my kettle at a specified temperature (and/or don't want to go through the trouble of relighting my burner, etc), I just wait for the wort to be below 175 and toss all the kids in the pool. am I missing out on some flavors that would have developed above that temperature? sure. but they probably aren't terribly significant and the unpredictability in the cooling of the vessel means my IBUs would be all over the place if I didn't do all of the bittering at 60.

- Joined

- Dec 16, 2015

- Messages

- 935

- Reaction score

- 355

I'm doing .75oz of warrior at 60min for a 5 gallon batch, which comes down to .5oz when I make a 3-3.5gallon batch. Everything else is flame out and WP. 3oz at flameout, 3 oz at 160° WP. Then two dry hops. The aim was 35IBU from the 60min addition and the rest from flameout and WP.

All the above is from Braufessor's NE IPA thread. Amazingly good beer that will get you close to julius.

All the above is from Braufessor's NE IPA thread. Amazingly good beer that will get you close to julius.

Similar threads

- Replies

- 0

- Views

- 697

- Replies

- 9

- Views

- 10K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)