MSUCatBrewer

Well-Known Member

Second all-grain batch today...and it tested my mettle as a new home brewer...and a VERY new AG brewer.

Newcastle Brown Ale Clone.

Grain Bill:

6 oz English Crystal Malt

8.5 LB Pale Ale Malt

1.5 LB Flaked Maize

3 oz Chocolate Malt

Total: 10.56 LB

First issue: I use a Barley Crusher. My 1st AG batch I milled at .038 and I didn't get very good efficiency. I set my mill to 0.36 and the first hopper went through like magic. The 2nd hopper I couldn't get to go...I fiddled and fiddled and fiddled, finally set it back to 0.38 and it went right through...frustrating, but no big deal.

Couldn't get my mash temp down to the recommended 150 F after striking at 170 F...it stalled at 157 F. I added (3) ice cubes, it dropped to 153 F, and I called it good. Tun didn't lose so much as 1/2 a degree.

Second Issue: My manifold ended up near vertical inside the grain bed...I'm guessing a symptom of my dough-in stirring. It kept stalling during vorlauf. I kept blowing air back through the tube, and got the vorlauf done. During fly sparge, it kept stalling. I eventually re-stirred the mash and got my kettle volume. Next time I will tuck the manifold under the brass interior valve baring it that should solve that problem. Moving on.

Third Issue: I had a 1oz pack of Kent Golding hops, of which I was only supposed to use 1/2 oz. I knew this, made a note of it, but got in a hurry and dumped the whole thing in. I suppose I'll just have a hoppier brown ale. Hopefully this won't wreck the beer...I don't think it will.

Fourth Issue: With 4:49 left, I ran OUT OF PROPANE! STUPID! I did the lift test and thought I had enough. AG brewing takes way more propane. I guessed wrong. Won't make that mistake again. I was down for EXACTLY 13 min (luckily the grocery store wasn't busy this evening), got hooked back up, added 10 min to my boil time, and wrapped it up.

Fifth Issue: My hose sprung a leak during cooling with my Copper Circulation Chiller. Just bad luck there...thankfully had a backup hose.

Sixth Issue: I forgot to check brewhouse efficiency.

Seventh Issue: I missed my SG. It was estimated at 1.051, I came in at 1.047. Oh well.

I used White Labs English Ale 002. I made a starter for the first time and it seemed pretty spunky...no issues there. I pitched, cleaned up, and pounded a beer...and then another.

I still need to get more organized...I think I'm ready...and then I drive myself crazy. I've learned that homebrewing is "hurry up and wait" until about 10 min left in the boil and then it's balls to the wall. I'll keep working on that...

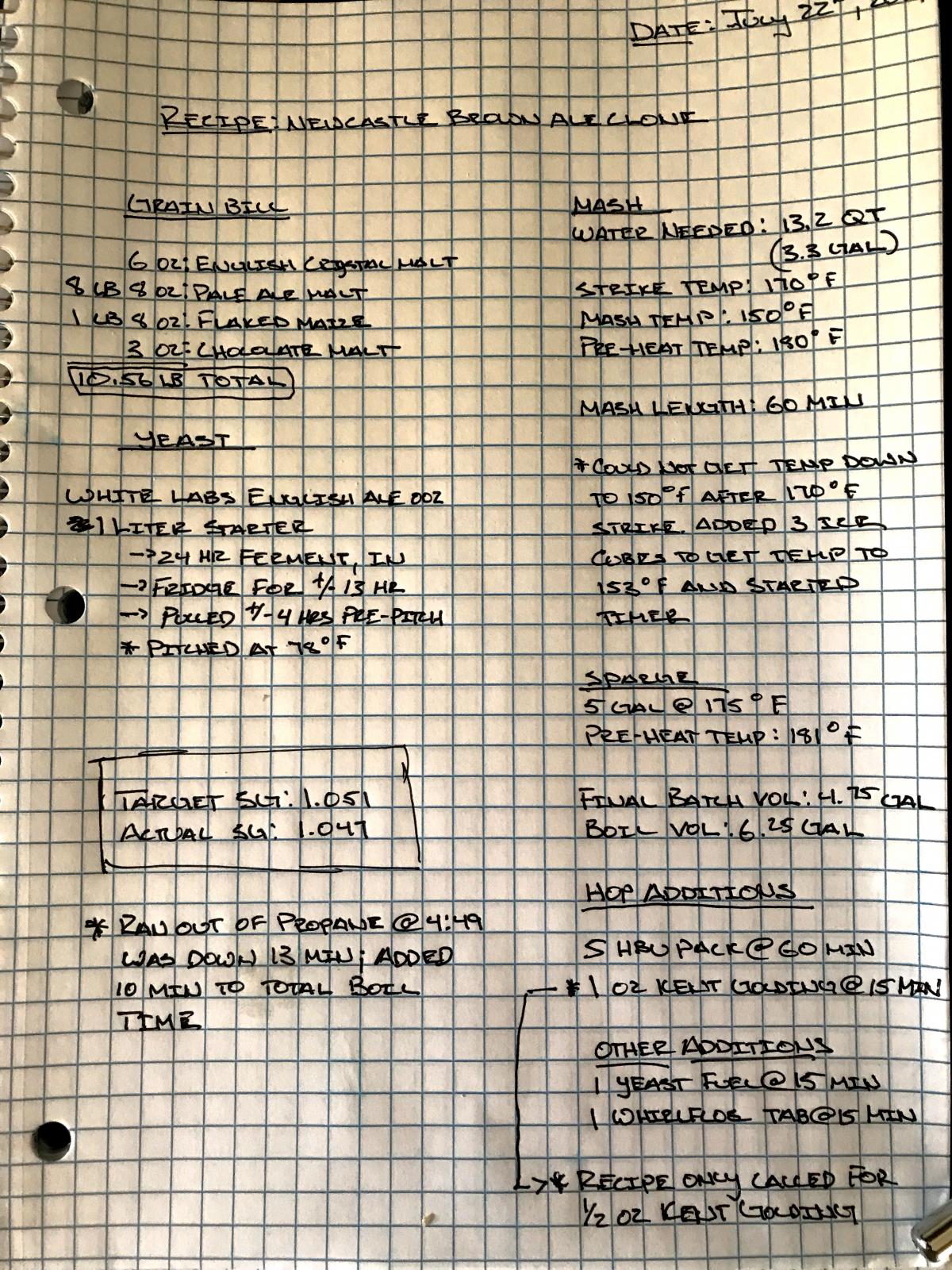

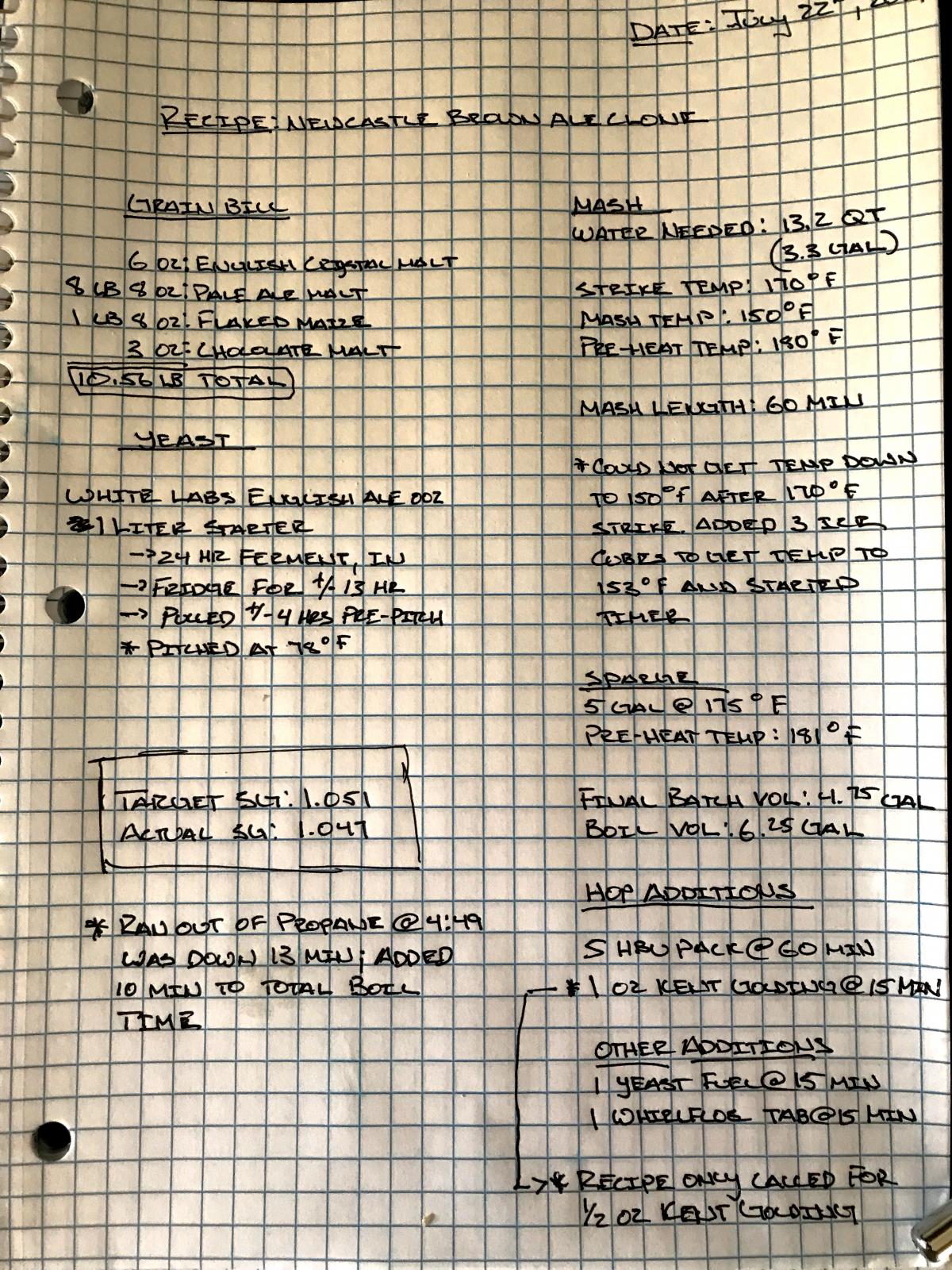

I've attached a picture of my notes...I like graph paper and it's kinda hard to read; I'll use blue pen next time. If anybody has recommendations, as always, I'll be very thankful!

Until next time friends!

Newcastle Brown Ale Clone.

Grain Bill:

6 oz English Crystal Malt

8.5 LB Pale Ale Malt

1.5 LB Flaked Maize

3 oz Chocolate Malt

Total: 10.56 LB

First issue: I use a Barley Crusher. My 1st AG batch I milled at .038 and I didn't get very good efficiency. I set my mill to 0.36 and the first hopper went through like magic. The 2nd hopper I couldn't get to go...I fiddled and fiddled and fiddled, finally set it back to 0.38 and it went right through...frustrating, but no big deal.

Couldn't get my mash temp down to the recommended 150 F after striking at 170 F...it stalled at 157 F. I added (3) ice cubes, it dropped to 153 F, and I called it good. Tun didn't lose so much as 1/2 a degree.

Second Issue: My manifold ended up near vertical inside the grain bed...I'm guessing a symptom of my dough-in stirring. It kept stalling during vorlauf. I kept blowing air back through the tube, and got the vorlauf done. During fly sparge, it kept stalling. I eventually re-stirred the mash and got my kettle volume. Next time I will tuck the manifold under the brass interior valve baring it that should solve that problem. Moving on.

Third Issue: I had a 1oz pack of Kent Golding hops, of which I was only supposed to use 1/2 oz. I knew this, made a note of it, but got in a hurry and dumped the whole thing in. I suppose I'll just have a hoppier brown ale. Hopefully this won't wreck the beer...I don't think it will.

Fourth Issue: With 4:49 left, I ran OUT OF PROPANE! STUPID! I did the lift test and thought I had enough. AG brewing takes way more propane. I guessed wrong. Won't make that mistake again. I was down for EXACTLY 13 min (luckily the grocery store wasn't busy this evening), got hooked back up, added 10 min to my boil time, and wrapped it up.

Fifth Issue: My hose sprung a leak during cooling with my Copper Circulation Chiller. Just bad luck there...thankfully had a backup hose.

Sixth Issue: I forgot to check brewhouse efficiency.

Seventh Issue: I missed my SG. It was estimated at 1.051, I came in at 1.047. Oh well.

I used White Labs English Ale 002. I made a starter for the first time and it seemed pretty spunky...no issues there. I pitched, cleaned up, and pounded a beer...and then another.

I still need to get more organized...I think I'm ready...and then I drive myself crazy. I've learned that homebrewing is "hurry up and wait" until about 10 min left in the boil and then it's balls to the wall. I'll keep working on that...

I've attached a picture of my notes...I like graph paper and it's kinda hard to read; I'll use blue pen next time. If anybody has recommendations, as always, I'll be very thankful!

Until next time friends!