Morrey

Well-Known Member

I recently visited White Labs new facility in Asheville NC where I tried a 4-way split batch of various WL yeasts in IPA beers. The WLP 066 totally took me by a pleasant surprise at the difference between this and WLP001, WLP008 and Sacc Trois. This lead me to my own split batch experiment with WLP066 and WY1318 which is truly my go to yeast for a NE IPA. Can the "King" 1318 be dethroned?

The NE IPA recipe I always use is from @Braufessor plus my IPA specialist brew buddy @TravelingLight weighed in to help me make a tweak here or there as a final adjustment on the grain bill.

Hops were Galaxy/Mosaic/Citra, and brewing salts ratios were 150ppm Chlorides to 75ppm Sulfates. Other than that, I wasn't really interested in picking apart the beer's grain and hop bills per se, but was focused on all the differences the two beers offered strictly as a function of the two different yeasts.

Spinning up the two yeasts in side by side flasks showed the more aggressive speed of 1318. Within the same afternoon building the starters, the 1318 started forming a krausen head, and the 066 had not shown signs of forming a ring yet. Lesson learned is that 066 needed 20-24 hours to come to a full krausen while the 1318 peaked in 16-18 hours. I'll also add that the date of mfg of these two yeasts was within a week of each other.

The 13G brew itself was uneventful and 1.060 wort was split 6.5G each into identical tanks and cooled down to 73F at which point the yeast was pitched. I chose this temp since both starters were at 73F on my counter and I wanted to pitch at these same temps. Once pitched, I step lowered the temps down to 68F (my ferm temp) over the next 2 hours. Fermenters are identical Ss 7G Uni tanks controlled by FTSs systems inc heaters and a glycol chiller. Every detail was as identical as possible.

As expected, the tank with 1318 started off gassing in less than 12 hours - then in 18 hours it was fully engaged. Lagging behind (again, as expected from the starter), the 066 took 18 hours to show any off gassing, then in 24 hours it was fully engaged as well. Since these two tanks were not on the same fermentation schedule, I decided not to do an early biotransformation dry hop, so I waited for both beers stabilize before dry hopping. By day 6, both beers were still, but I waited until day 9 to dry hop. I dry hopped both tanks identically for the same amount of time which was 2 days before removing the hop strainers.

After 11 days and dry hopping finished, both tanks showed stable FG's, so I slowly started lowering the temps. I did this very gradually as in 5F in the am, then another 5F in the evening. By day 14 I was around the 40F mark so that's where the beer was kegged.

I'll post pics of the beers side by side as well as a taste comparison by several folks who know and appreciate the subtleties of good IPA beers.

The Ss system does a fantastic job keeping sister tanks at the exact same temps.

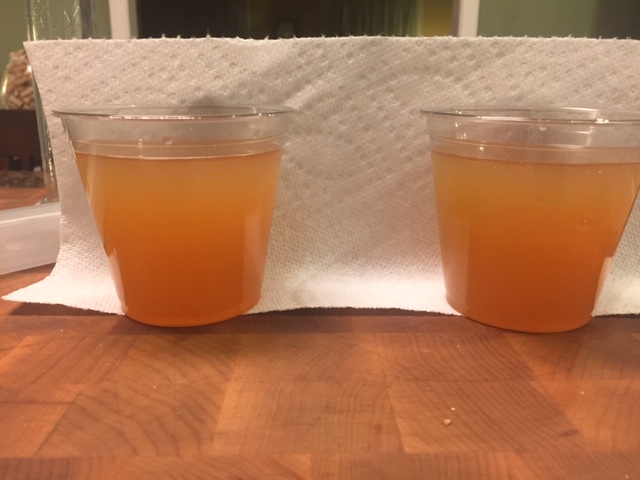

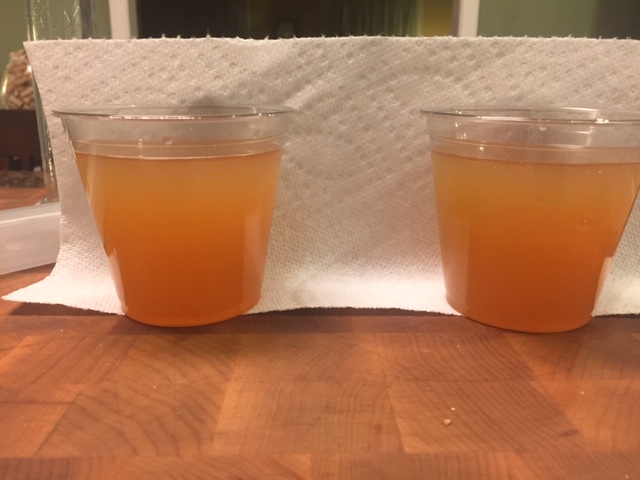

Interesting was that both beers came out to exactly the same FG which was 1.012. Beers were carbed to the same level and same serving temps. These beers LOOKED identical and none of us could visually separate the 066 from the 1318.

WLP 066 on the left

Tasting was blind sampled by me, my wife and a home brew buddy turned pro. My wife did my evaluation separately so I would not see. All of us agreed both beers were outstanding representatives of this style. All of us also agreed the 066 was SLIGHTLY smoother on the trailing edge and was more rounded on the palate. 1318, by contrast, was more straightforward and packed a bit more hop pronounced upfront punch that lingered to the finish. This was a real tough call to pick a favorite since I like the hop forward punch in an IPA while the wife liked the smoother edge. My brewer friend liked both equally, my wife preferred the 066 and I would pick the 1318 in a pinch.

Clearly, there is not much of a difference. I like either and both...a pro brewer had no preference as they are too close to differentiate. Going forward, I'd make a decision based on the age of the yeast and the price difference if buying in a LHBS. Honestly, I like both equally and wouldn't turn around for the difference. Lets call this one a dead heat and a tie for outstanding beers produced from two of the best yeasts out there.

The NE IPA recipe I always use is from @Braufessor plus my IPA specialist brew buddy @TravelingLight weighed in to help me make a tweak here or there as a final adjustment on the grain bill.

Hops were Galaxy/Mosaic/Citra, and brewing salts ratios were 150ppm Chlorides to 75ppm Sulfates. Other than that, I wasn't really interested in picking apart the beer's grain and hop bills per se, but was focused on all the differences the two beers offered strictly as a function of the two different yeasts.

Spinning up the two yeasts in side by side flasks showed the more aggressive speed of 1318. Within the same afternoon building the starters, the 1318 started forming a krausen head, and the 066 had not shown signs of forming a ring yet. Lesson learned is that 066 needed 20-24 hours to come to a full krausen while the 1318 peaked in 16-18 hours. I'll also add that the date of mfg of these two yeasts was within a week of each other.

The 13G brew itself was uneventful and 1.060 wort was split 6.5G each into identical tanks and cooled down to 73F at which point the yeast was pitched. I chose this temp since both starters were at 73F on my counter and I wanted to pitch at these same temps. Once pitched, I step lowered the temps down to 68F (my ferm temp) over the next 2 hours. Fermenters are identical Ss 7G Uni tanks controlled by FTSs systems inc heaters and a glycol chiller. Every detail was as identical as possible.

As expected, the tank with 1318 started off gassing in less than 12 hours - then in 18 hours it was fully engaged. Lagging behind (again, as expected from the starter), the 066 took 18 hours to show any off gassing, then in 24 hours it was fully engaged as well. Since these two tanks were not on the same fermentation schedule, I decided not to do an early biotransformation dry hop, so I waited for both beers stabilize before dry hopping. By day 6, both beers were still, but I waited until day 9 to dry hop. I dry hopped both tanks identically for the same amount of time which was 2 days before removing the hop strainers.

After 11 days and dry hopping finished, both tanks showed stable FG's, so I slowly started lowering the temps. I did this very gradually as in 5F in the am, then another 5F in the evening. By day 14 I was around the 40F mark so that's where the beer was kegged.

I'll post pics of the beers side by side as well as a taste comparison by several folks who know and appreciate the subtleties of good IPA beers.

The Ss system does a fantastic job keeping sister tanks at the exact same temps.

Interesting was that both beers came out to exactly the same FG which was 1.012. Beers were carbed to the same level and same serving temps. These beers LOOKED identical and none of us could visually separate the 066 from the 1318.

WLP 066 on the left

Clearly, there is not much of a difference. I like either and both...a pro brewer had no preference as they are too close to differentiate. Going forward, I'd make a decision based on the age of the yeast and the price difference if buying in a LHBS. Honestly, I like both equally and wouldn't turn around for the difference. Lets call this one a dead heat and a tie for outstanding beers produced from two of the best yeasts out there.

Last edited: