Stand

Well-Known Member

That and a wi-fi Inkbird that lets you monitor and control temp remotely (and go on vacations during fermentation with less stress!). "Set it and forget it" across almost any temp is wonderful! I'm now about to dabble in the world of Tilt hydrometers, which will be "nice to have" but will not have the same impact of the glycol chiller and wi-fi controller, which are now essential tools for me.

If you like that wi-fi Inkbird, you should check out what a Fermentrack or BrewPiLess can do. Absolutely insane amount of control. I can schedule a fermentation profile, track my Tilt hydrometer, record fermentation procedure, and it controls temps within .1 degree.

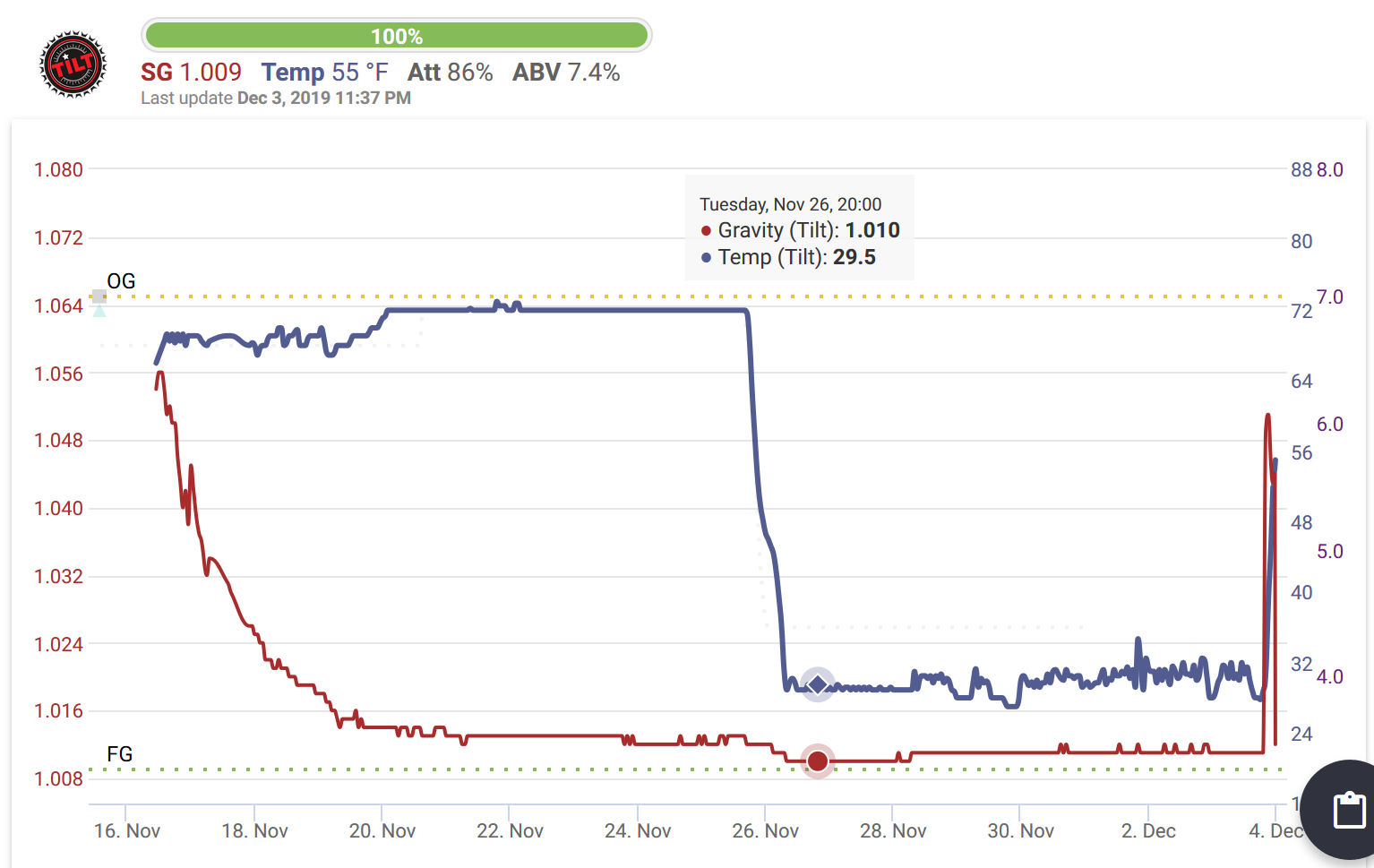

I didn't think a Tilt would be as big a deal as it turned out to be. Watching the arc as your fermentation reaches FG is intensely satisfying, but it also lets you be 100% sure when the fermentation is finished.

BrewPi requires some DIY soldering, but it's not too bad. Fantastic project if you're into that kind of thing.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)