I believe my issue on this last brew was that I had the mash recirc too slow. Which theoretically, I should be picking up more heat from the HLT/HERMS due to slower speed and longer time inside the HERMS coil, however that was not the case.

My process is pretty close to yours.

The recipe calls for single mash rest at 152F. Beersmith calls for my strike water to be at 165 to account for temp loss when I add the grain.

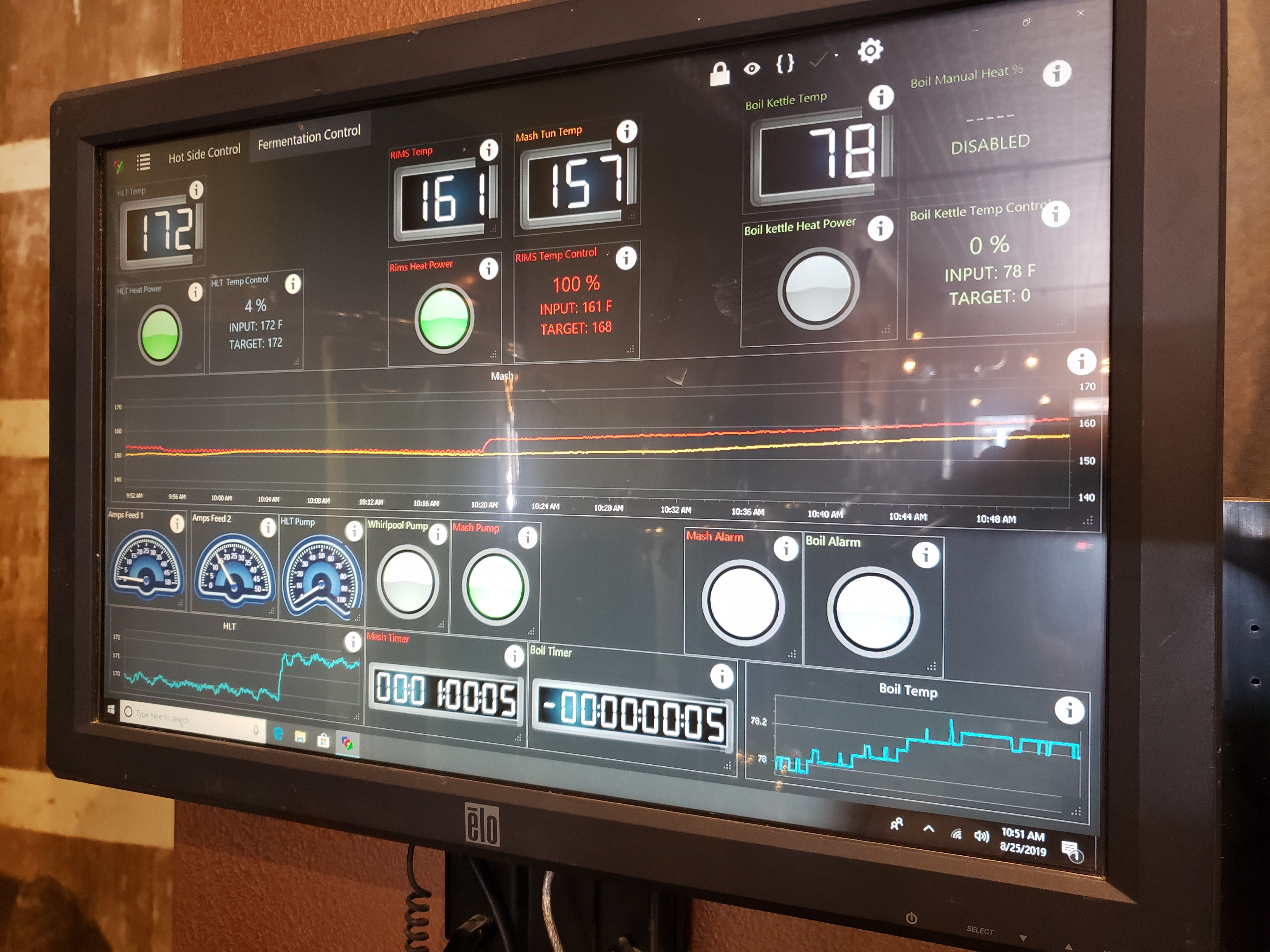

- To get the water in my mash tun to 165 I set my panel to 175 because it is faster heating the strike water when the HLT is much hotter.

- Press go and begin to heat HLT water with a pump recirculating it in the HLT

- Fill my mash tun to the strike water level calculated by beersmith (7.88 gallons in this case)

- Begin recirculating my strike water through the HERMS coil (so now I'm heating both HLT and mash water at the same time).

- Wait until my mash water is at strike temp (added acids/campden/brewing salts)

- Reduce HLT controller to 3 degrees above mash temp. (This differential works perfect when recirc is full bore, I am still dialing in the temp with recirc throttled back. Towards the end of my last brew I opened up the recirc valve and the differential was closer to 5 degrees.)

- Add cold water to HLT to help drop temp quickly

- Turn off my wort pump and close MT valve - at this point my mash tun water is at 165 and my HLT water is at 157

- Mash in grain and stir, ensuring that the temp levels off at 152

- Let the mash sit for 5 minutes covered

- Stir the mash

- Turn wort pump back on and throttle back to about 1/4 open.

- I watch the mash tun outlet temperature (mash going TO the HERMS coil) as an indicator of bulk mash temp - if it starts to drop over the course of my 60 minute mash, I will raise my HLT temp by 2-4 degrees to compensate but I rarely need to do this.

- At the end of 60 minutes I shut off the mash recirc, add silicone hose to mash recirc port, and switch hoses around for the sparge - and simultaneously set the HLT to 168

- Once the HLT hits 168 I'll start sparging

My issue the last brew was during step 6, I had the Mash recirc barely cracked (trickle) and in order to keep my Mash temp anywhere near 152, I had to turn the HLT temp up. (15°-18° higher than mash) Once I opened up the mash recirc a bit (slow stream) the differential was closer to 5°.